Pure styrene-acrylic architectural emulsion and preparing method thereof

A styrene-acrylic construction and emulsion technology, applied in the coating and other directions, can solve the problems of affecting the normal progress of the polymerization reaction, reducing the stability of the emulsion, affecting the storage stability, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

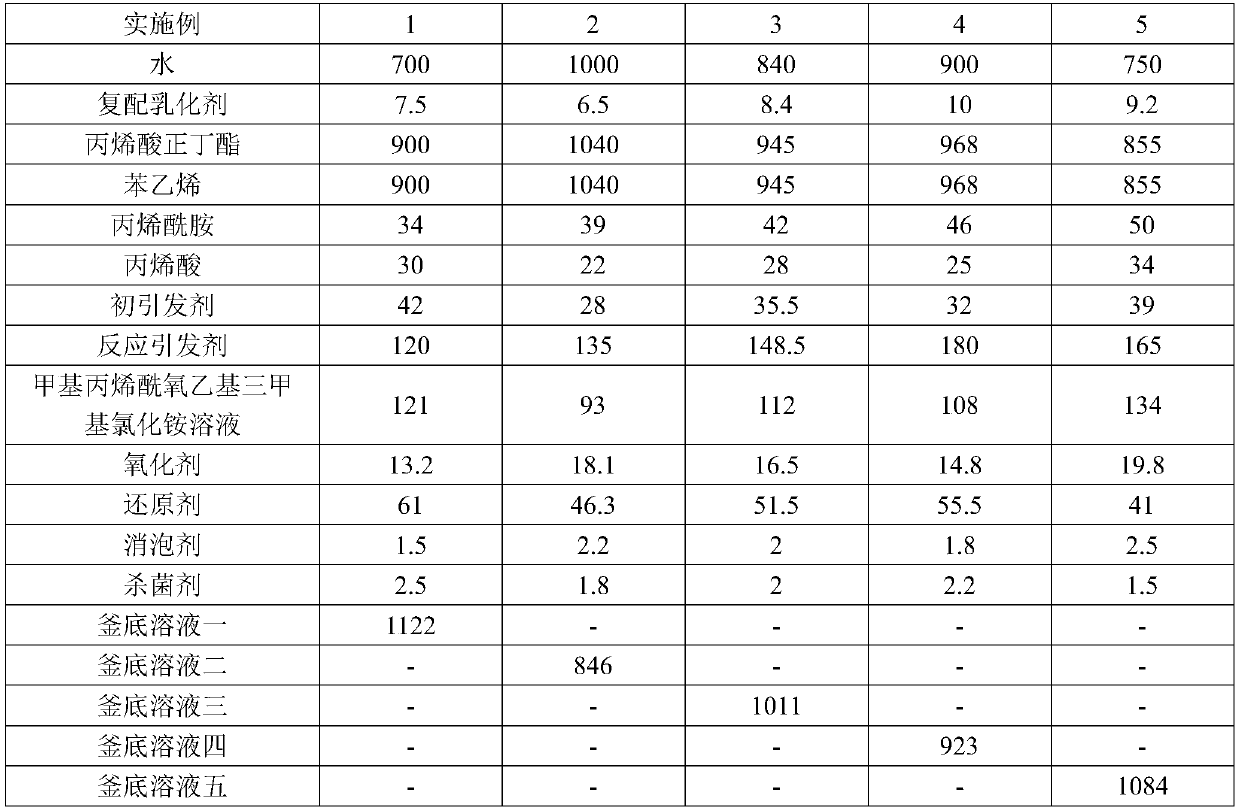

[0042] A kind of pure styrene-acrylic building emulsion, its raw material ratio is shown in Table 1, Table 2;

[0043] (1) In the mixing kettle, water, allyloxy hydroxypropyl sulfonate sodium reactive emulsifier, and sodium bicarbonate are mixed evenly to obtain the solution at the bottom of the kettle, which is set aside;

[0044] (2) In another mixing tank, mix water, compound emulsifier, n-butyl acrylate, styrene, acrylamide, and acrylic acid evenly, and the weight ratio of n-butyl acrylate and styrene is 1:1 , to obtain a mixed monomer solution for subsequent use;

[0045] (3) Add still bottom solution in reactor, and under the condition that temperature is 83 ℃, add initial initiator in the still bottom solution in reactor, initial initiator selects mass fraction for use and is the ammonium persulfate solution of 18.33% , and the initial initiator was prepared 30 minutes before adding to the reactor, the temperature was controlled at 86°C, and then the mixed monomer solu...

Embodiment 2

[0050] A kind of pure styrene-acrylic building emulsion, its raw material ratio is shown in Table 1, Table 2;

[0051] (1) In the mixing kettle, water, allyloxy hydroxypropyl sulfonate sodium reactive emulsifier, and sodium bicarbonate are mixed evenly to obtain the solution at the bottom of the kettle, which is set aside;

[0052] (2) In another mixing tank, mix water, compound emulsifier, n-butyl acrylate, styrene, acrylamide, and acrylic acid evenly, and the weight ratio of n-butyl acrylate and styrene is 1:1 , to obtain a mixed monomer solution for subsequent use;

[0053] (3) Add still bottom solution in reactor, and under the condition that temperature is 83 ℃, add initial initiator in the still bottom solution in reactor, initial initiator selects mass fraction for use and is the ammonium persulfate solution of 18.33% , and the initial initiator was prepared 20 minutes before adding to the reactor, the temperature was controlled at 86°C, and then the mixed monomer solu...

Embodiment 3

[0058] A kind of pure styrene-acrylic building emulsion, its raw material ratio is shown in Table 1, Table 2;

[0059] (1) In the mixing kettle, water, allyloxy hydroxypropyl sulfonate sodium reactive emulsifier, and sodium bicarbonate are mixed evenly to obtain the solution at the bottom of the kettle, which is set aside;

[0060] (2) In another mixing tank, mix water, compound emulsifier, n-butyl acrylate, styrene, acrylamide, and acrylic acid evenly, and the weight ratio of n-butyl acrylate and styrene is 1:1 , to obtain a mixed monomer solution for subsequent use;

[0061] (3) Add still bottom solution in reactor, and under the condition that temperature is 83 ℃, add initial initiator in the still bottom solution in reactor, initial initiator selects mass fraction for use and is the ammonium persulfate solution of 18.33% , and the initial initiator was prepared 10 minutes before adding to the reactor, the temperature was controlled at 86°C, and then the mixed monomer solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com