Dual-functional electrocatalyst Pt-IrO2 and preparation method

A pt-iro2, catalyst technology, applied in the field of electrocatalysis, can solve problems such as unsolved defects, and achieve the effects of easy removal, high catalytic performance, and high active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

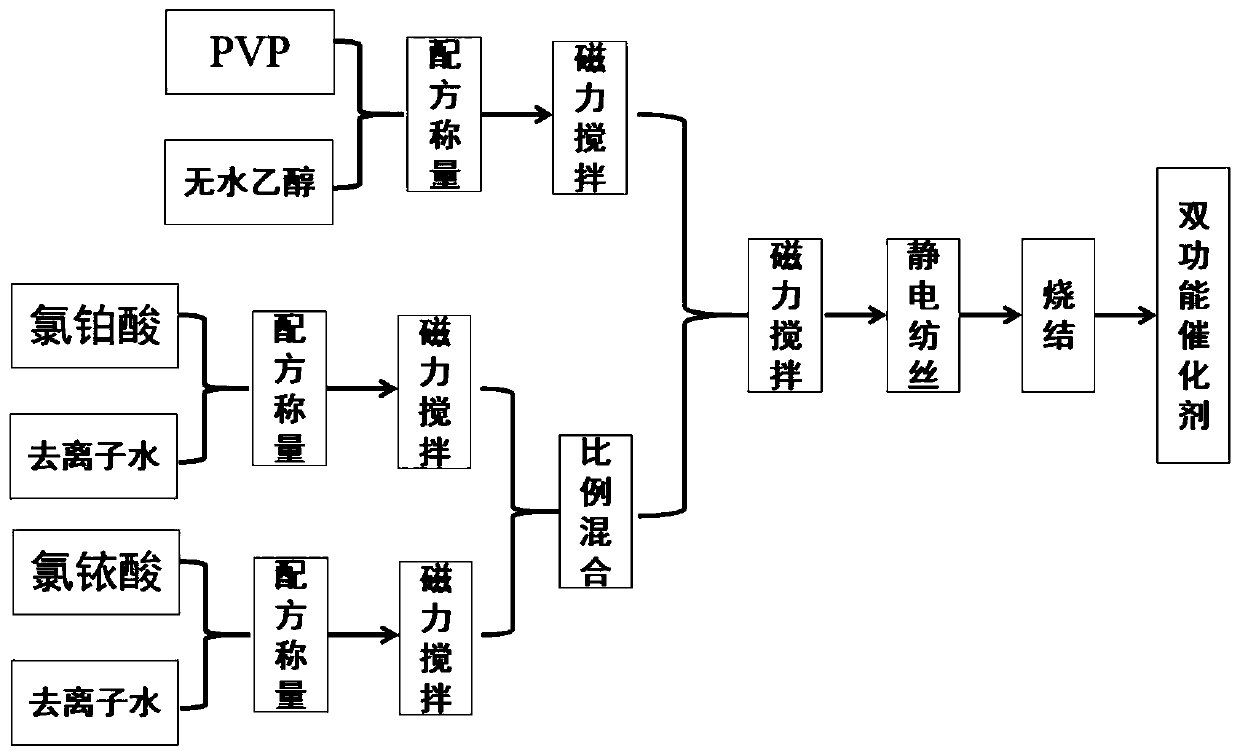

[0031] Step 1: Take a certain amount of polyvinylpyrrolidone and add absolute ethanol, and stir magnetically to prepare an 8wt% PVP solution.

[0032] Step 2, respectively take 1 g of chloroiridic acid and chloroplatinic acid and add deionized water and stir to obtain a chloroplatinic acid solution and a chloroiridic acid solution with a Pt and Ir content of 0.34 mol / L.

[0033] Step 3: After mixing the solutions in step 2 according to the ratio of Pt / Ir=1:9, add a certain amount of PVP solution in step 1, and magnetically stir for 12 hours to obtain the spinning precursor solution.

[0034] Step 4, adding the precursor solution into the electrospinning equipment, the spinning voltage is 12KV, the spinning distance is 10cm, and the solution propulsion rate is 0.15ml / h.

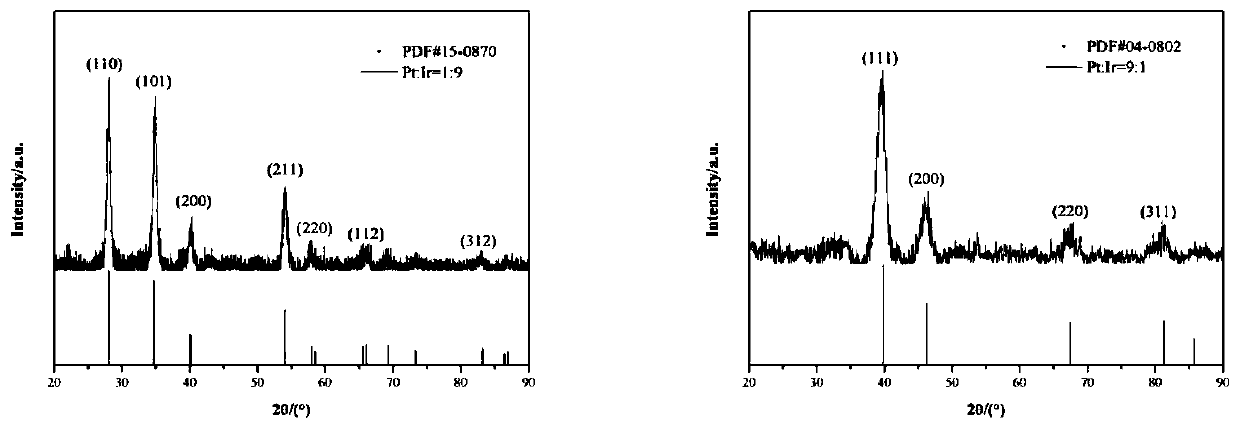

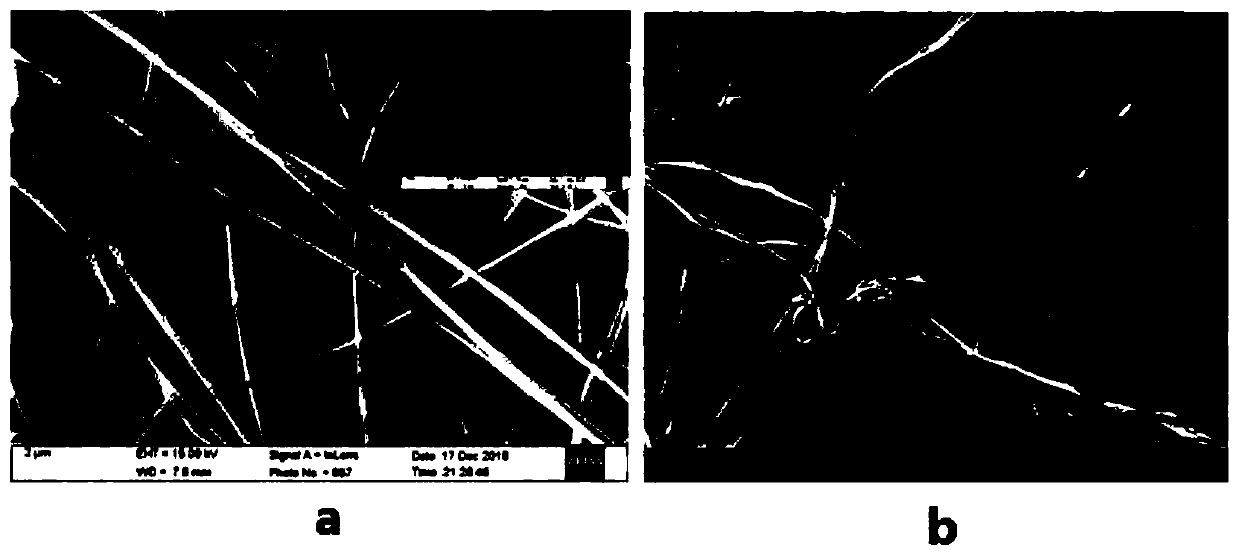

[0035] Step 5: Collect the spun nanofibers (flat ribbon structure, width 200nm-600nm) and calcinate them in an air atmosphere at a heating rate of 0.75°C / min, first raise the temperature to 260°C and keep it f...

Embodiment 2

[0037] Step 1: Take a certain amount of polyvinylpyrrolidone and add absolute ethanol, and stir magnetically to prepare an 8wt% PVP solution.

[0038] Step 2, respectively take 1 g of chloroiridic acid and chloroplatinic acid and add deionized water and stir to obtain a chloroplatinic acid solution and a chloroiridic acid solution with a Pt and Ir content of 0.17 mol / L.

[0039] Step 3: After mixing the solutions in step 2 according to the ratio of Pt / Ir=1:9, add a certain amount of PVP solution in step 1, and magnetically stir for 12 hours to obtain the spinning precursor solution.

[0040] Step 4, adding the precursor solution into the electrospinning equipment, the spinning voltage is 12KV, the spinning distance is 10cm, and the solution propulsion rate is 0.15ml / h.

[0041] Step 5: Collect the spun nanofibers (nanowire structure, diameter 220nm-350nm) and calcinate them in an air atmosphere at a heating rate of 0.75°C / min, first raise the temperature to 260°C for 1 hour, t...

Embodiment 3

[0043] Step 1: Take a certain amount of polyvinylpyrrolidone and add absolute ethanol, and stir magnetically to prepare an 8wt% PVP solution.

[0044] In step 2, 1 g of chloroiridic acid and chloroplatinic acid were added into deionized water and stirred to obtain a chloroplatinic acid solution and a chloroiridic acid solution with a Pt and Ir content of 0.085 mol / L.

[0045] Step 3: After mixing the solutions in step 2 according to the ratio of Pt / Ir=3:7, add a certain amount of PVP solution in step 1, and magnetically stir for 12 hours to obtain the spinning precursor solution.

[0046] Step 4, adding the precursor solution into the electrospinning equipment, the spinning voltage is 12KV, the spinning distance is 10cm, and the solution propulsion rate is 0.15ml / h.

[0047] Step 5, collect the spun nanofibers (nanowire structure, diameter 220nm-250nm, good uniformity), and calcinate in the air atmosphere, the heating rate is 0.75°C / min, the temperature is first raised to 260°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com