Mncozn-like ferrite and its manufacturing method

A manufacturing method and technology of ferrite, applied in chemical instruments and methods, cobalt compounds, magnetic properties of inorganic materials, etc., can solve the problems of insufficient grain boundary formation, reduced resistivity, etc., to inhibit the growth of abnormal particles and achieve good magnetic properties. Characteristics, effect of low coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

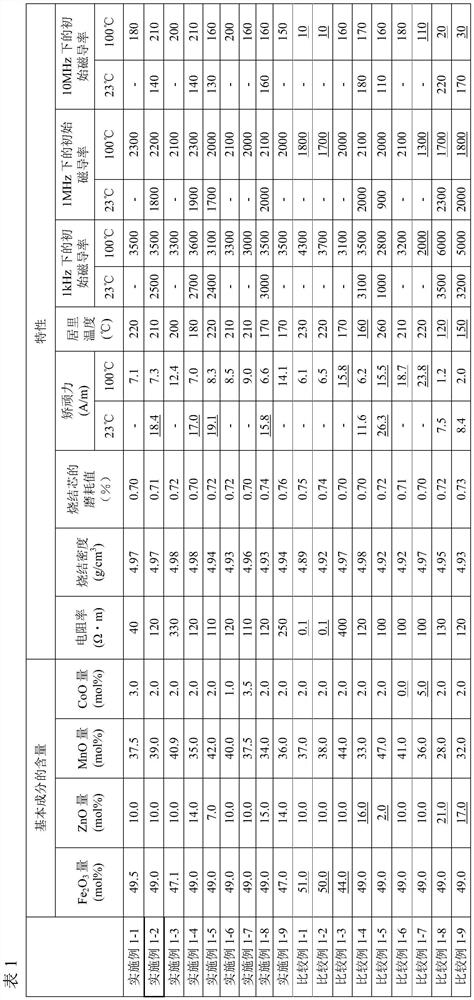

Embodiment 1

[0128] After converting all the iron, zinc, cobalt and manganese contained into Fe 2 o 3 , ZnO, CoO and MnO, weigh Fe according to the ratio shown in Table 1 2 o 3 , the amounts of ZnO, CoO and MnO, each raw material powder was mixed for 16 hours using a ball mill, and then calcined at 925° C. in air for 3 hours. Then, weigh 150 and 700 mass ppm equivalent SiO 2 and CaO, it was added to the calcined powder and pulverized using a ball mill for 12 hours. Next, polyvinyl alcohol was added to the obtained pulverized slurry, spray-dried and granulated at an exhaust air temperature of 250 °C, coarse powder was removed through a sieve with a mesh size of 350 μm, and then a pressure of 118 MPa was applied to form a ring core and rectangular core. In addition, due to the use of high-purity raw materials, and before use, media such as ball mills are thoroughly cleaned to reduce the mixing of components derived from other materials, so the impurities contained in the annular core an...

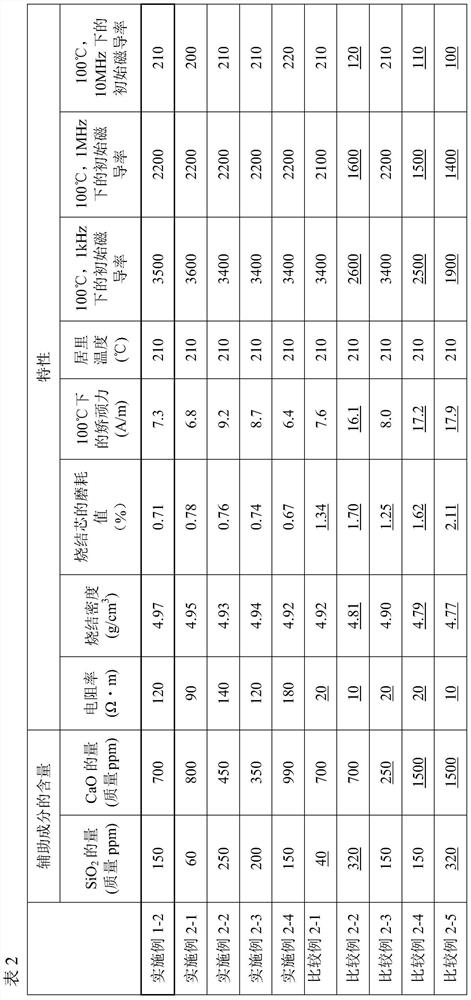

Embodiment 2

[0140] After converting all the iron, zinc, cobalt and manganese contained into Fe 2 o 3 , ZnO, CoO and MnO, according to Fe 2 o 3 A composition of 49.0 mol% ZnO, 10.0 mol% ZnO, 2.0 mol% CoO and the balance MnO Weigh the raw materials, mix them with a ball mill for 16 hours, and then calcinate them in air at 925°C for 3 hours. Then, the amount of SiO shown in Table 2 was added to the calcined powder 2 and CaO, and pulverized using a ball mill for 12 hours. Next, polyvinyl alcohol was added to the obtained pulverized slurry, spray-dried and granulated at an exhaust air temperature of 250 °C, coarse powder was removed through a sieve with a mesh size of 350 μm, and then a pressure of 118 MPa was applied to form a ring core and cylindrical core. The impurities Cd, Pb, Sb, As, and Se contained in the annular core and the cylindrical core were all 3 mass ppm, and Zr and Bi were 5 mass ppm. In addition, the particle size distribution d90 of the granulated powder used for moldi...

Embodiment 3

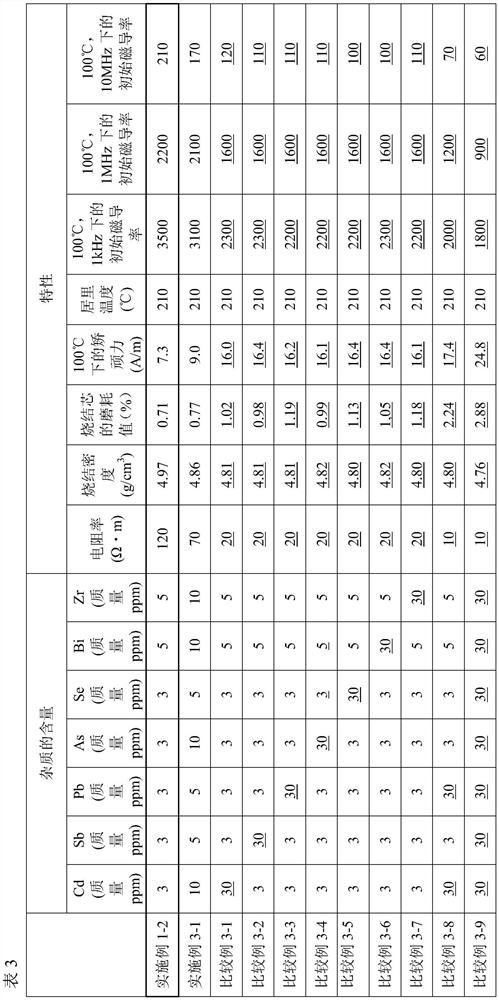

[0150] According to the method shown in Examples 1 and 2, the outer diameter is produced by using the basic ingredients and auxiliary ingredients in the same proportion as in Example 1-2, but using raw materials with different amounts of impurities, or adding ingredients intentionally: 25mm, inner diameter: 15mm, height: sintered body annular core of 5mm, and 5 diameters: 10mm, height: the cylindrical core of 10mm, use the same method and apparatus evaluation characteristic with embodiment 1, and the result that obtains is shown in Table 3. In addition, the particle size distribution d90 of the granulated powder used for molding was 230 μm, and the crushing strength was 1.29 MPa.

[0151] [table 3]

[0152]

[0153] As shown in the table, in Example 3-1 in which the contents of Cd, Pb, Sb, As, Se, Bi, and Zr were below the specified values, the strength expressed in terms of abrasion values, and the strength expressed in terms of wear at 100°C Magnetic properties indicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com