Composite flocculating agent for treating oil sand deposit tailings, and treating method for cured fine tailings

A composite flocculant and a treatment method technology are applied in the treatment field of composite flocculants and matured fine tailings, and can solve the problems that the treatment effect needs to be improved, the suspended matter in the supernatant is high, and the water content of the sediment is high, and the capillary suction can be achieved. The effect of short time, clear supernatant and high sediment solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 50% polyacrylamide (viscosity-average molecular weight 10 million, ionicity 30%), 30% polydimethyldiallylammonium chloride (relative molecular weight 500,000), 10% calcium carbonate, 9.5% The modified diatomite is mixed with 0.5% activated carbon to prepare a composite flocculant.

[0062] The appearance of the flocculating agent is gray solid particles, the effective content is ≥88%, and the density (20°C) is 0.7-0.8g / cm 3 , The pH value of 0.5% aqueous solution is 7-8.

Embodiment 2

[0064] After fully shaking the tailings sample, weigh 1000g and place it in a 1L beaker. The sample was stirred with a stirrer at a speed of 350 rpm for 3 minutes, then the speed was reduced to 160 rpm, and 0.05% of the aqueous flocculant solution prepared in Example 1 was added.

[0065] Once the flocculant solution is added, start timing, and the time for adding the flocculant is 1 minute, and continue to stir for 1 minute after adding. Turn off the agitator and transfer the flocculated tailings sample into a 1 L graduated cylinder with graduated paper. Start timing quickly, and record the sedimentation curve of the sedimentation height versus time.

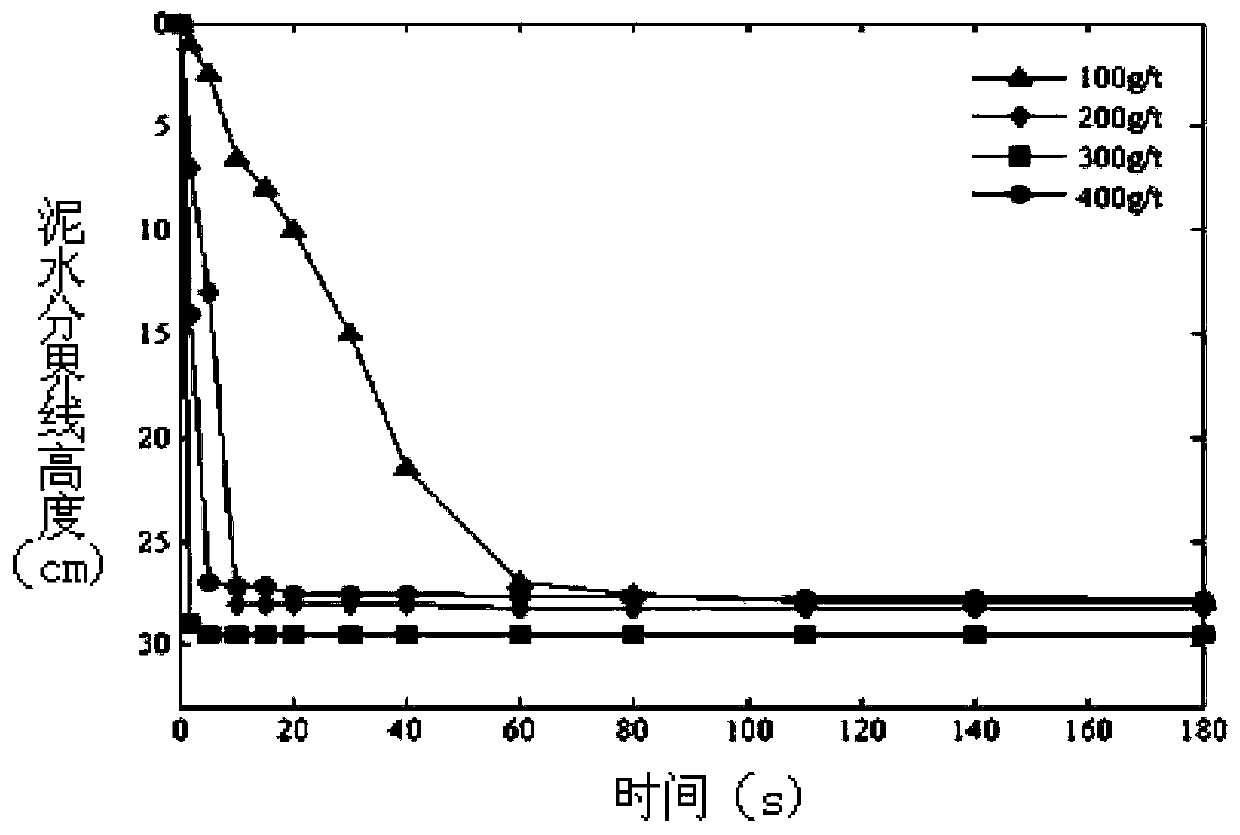

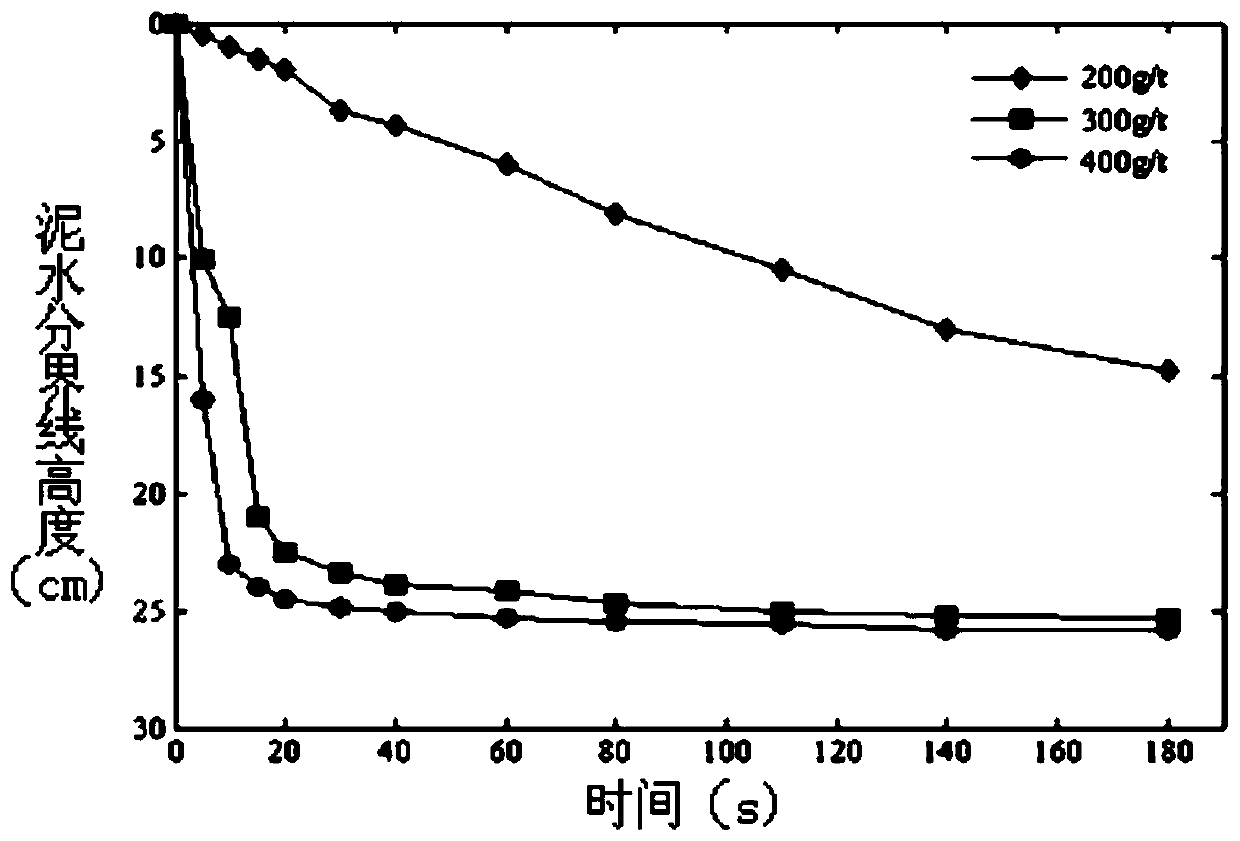

[0066] At the same time, do the sedimentation experiment of adding different dosages of the composite flocculant and polyacrylamide alone. For each settling curve, see figure 2 and image 3 , figure 2 It is the sedimentation curve of the composite flocculant of the present invention, and its dosage is respectively 100g / t...

Embodiment 3

[0072] 65% polyacrylamide (viscosity-average molecular weight 10 million, ionicity 30%), 5% polydimethyldiallyl ammonium chloride (relative molecular weight 500,000), 10% calcium carbonate, 19% The modified diatomite is mixed with 1% activated carbon to prepare a composite flocculant.

[0073] The appearance of the flocculating agent is gray solid particles, the effective content is ≥88%, and the density (20°C) is 0.7-0.8g / cm 3 , The pH value of 0.5% aqueous solution is 7-8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com