Biomedical Ti-Zr-Hf-Nb-Ta series high-entropy alloy and preparing method

A ti-zr-hf-nb-ta, high-entropy alloy technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problem of unfavorable implant materials used in biomedical fields, allergic reactions leading to cancer, and hindering metal ion and other issues, to achieve the effect of weakening the stress shielding effect, good biocompatibility, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

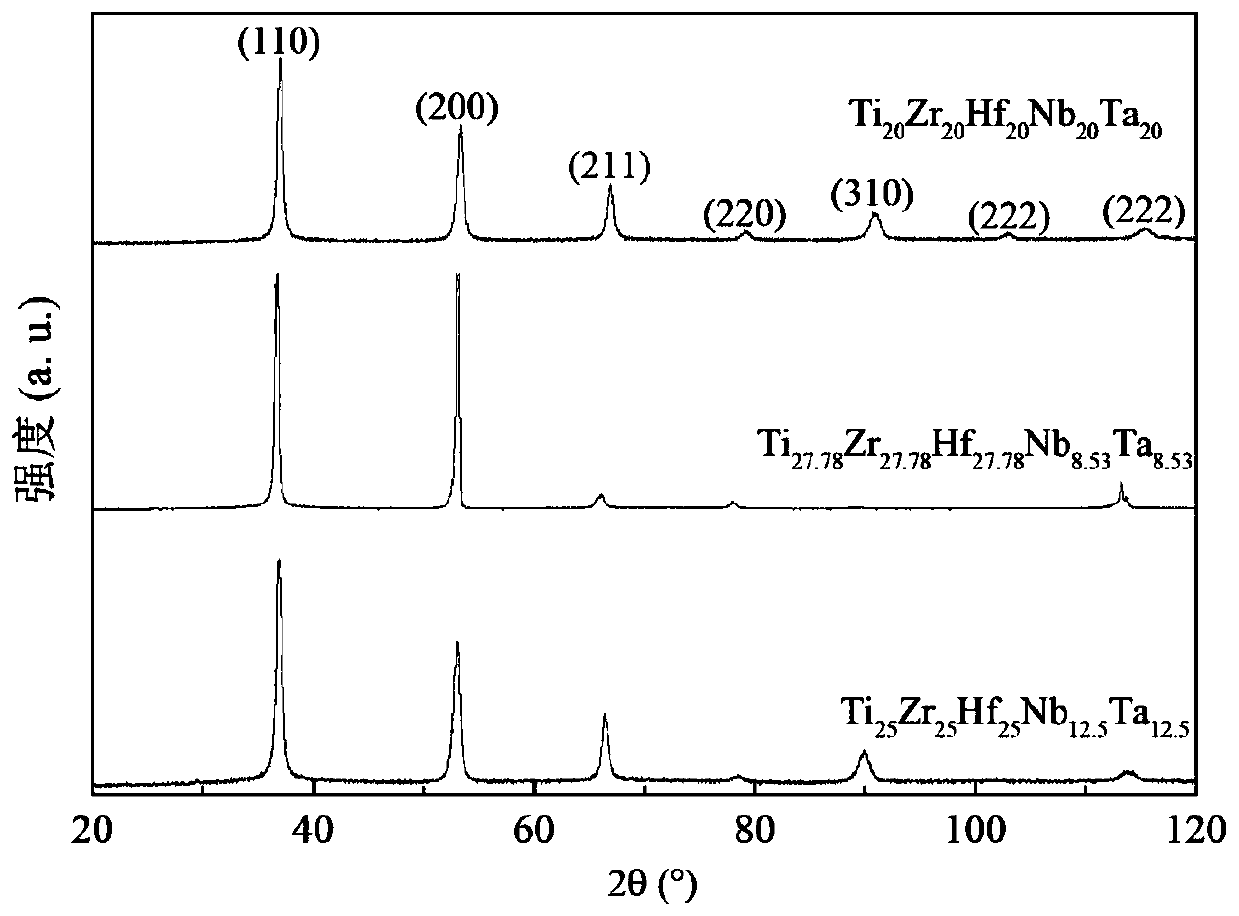

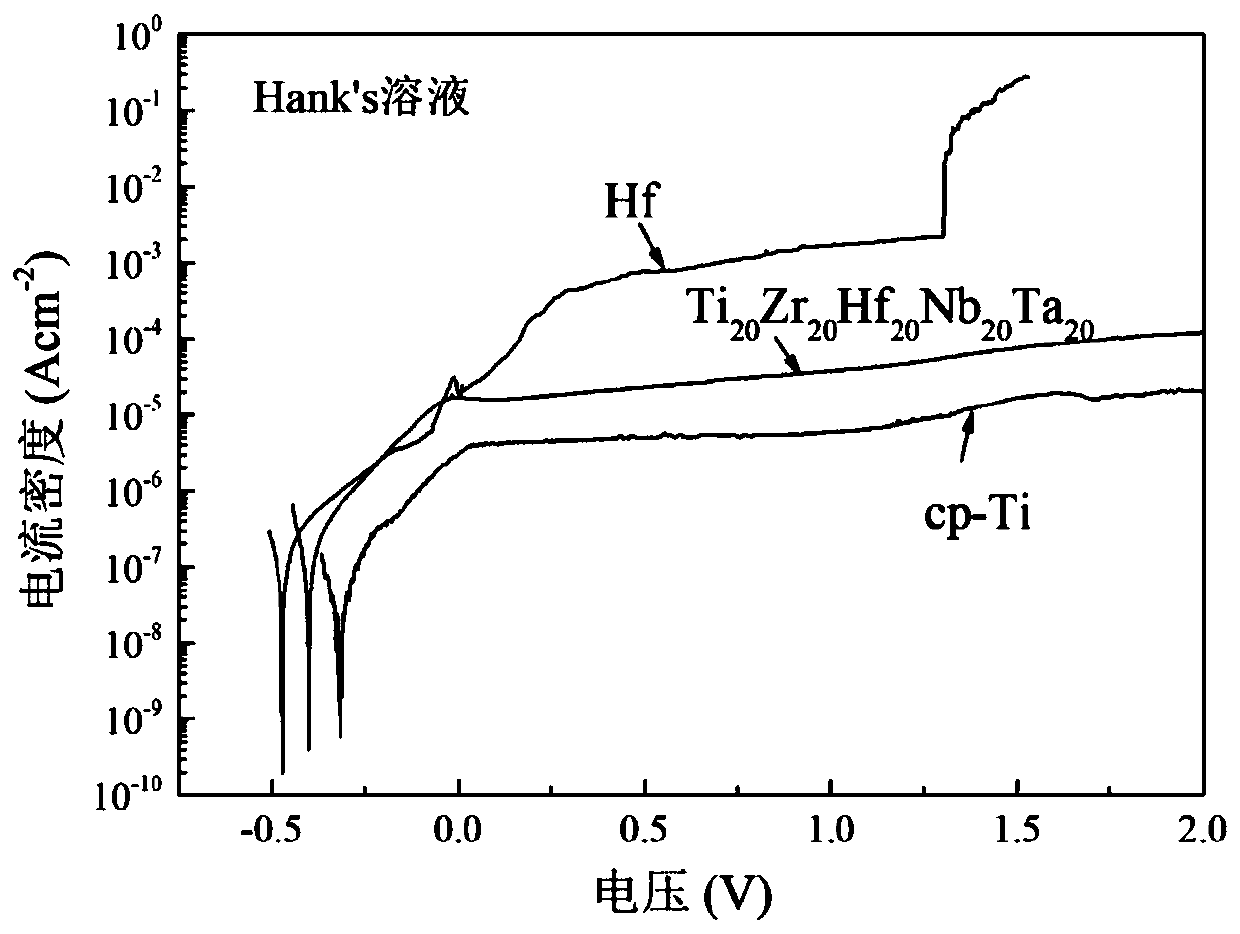

[0032] A biomedical Ti-Zr-Hf-Nb-Ta series high-entropy alloy, the general formula of the high-entropy alloy is: Ti a Zr b f c Nb d Ta e , where a, b, c, d, e are 20, 20, 20, 20, 20, respectively.

[0033] The present invention also provides a method for preparing a biomedical Ti-Zr-Hf-Nb-Ta high-entropy alloy, comprising the following steps:

[0034] Step 1, alloy ingredients: according to the composition of Ti-Zr-Hf-Nb-Ta high-entropy alloy, use a balance with a precision of 0.001g to have a purity of 99.99wt% Ti, 99.99wt% Zr, 99.95wt% Hf, and 99.8wt% Nb, 99.9 5wt% Ta for batching;

[0035] Step 2, alloy smelting: send the raw materials prepared in step 1 into the vacuum smelting furnace, and adjust the vacuum degree of the vacuum chamber of the vacuum smelting furnace to 2×10 -3 Pa, and then filled with argon with a purity higher than 99.8% as a protective gas, until the vacuum degree of the vacuum chamber is 0.1×10 5 Pa, then turn on the vacuum smelting furnace to smel...

Embodiment 2

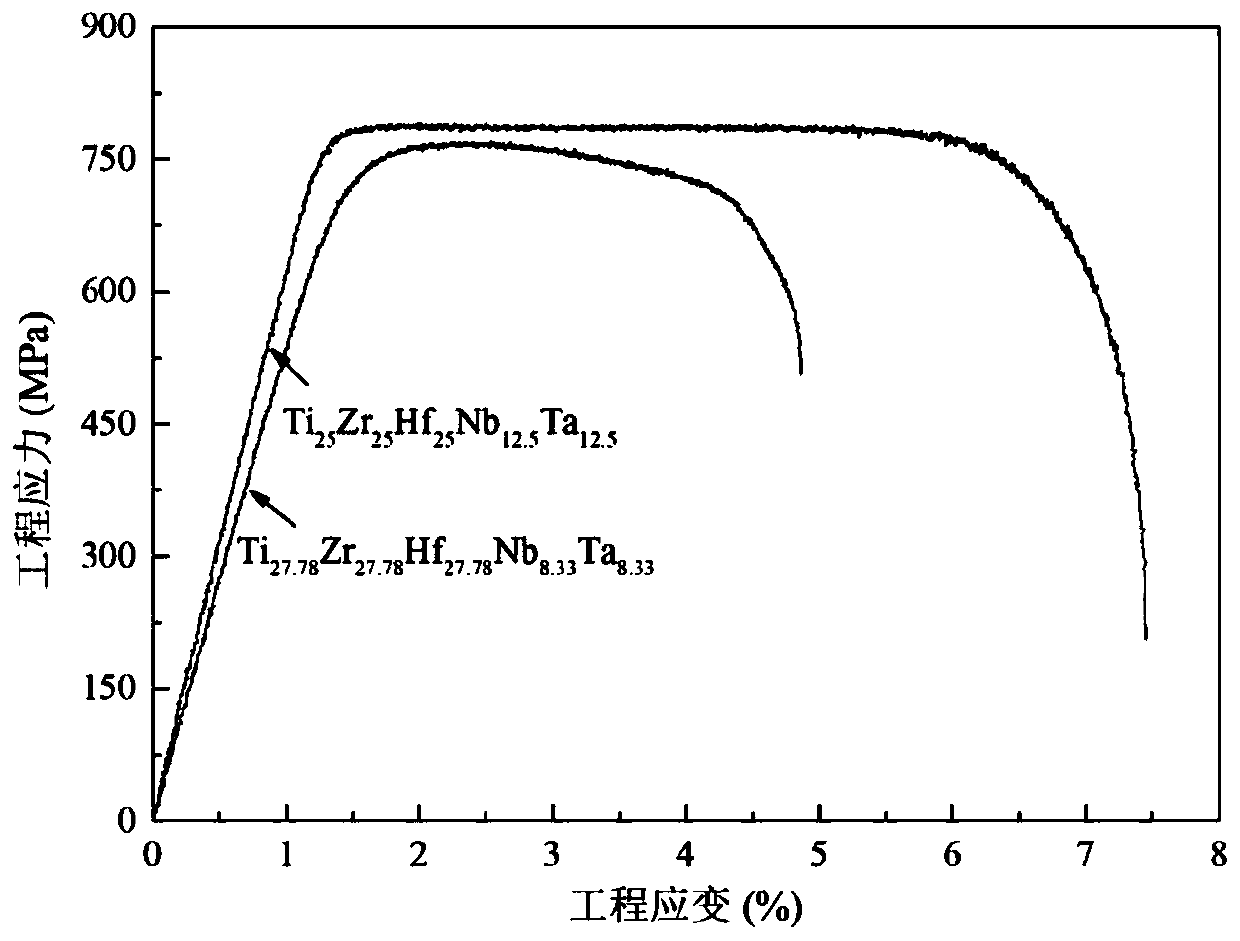

[0038] The only difference between this implementation and Example 1 is that Ti a Zr b f c Nb d Ta e Among them, a, b, c, d, and e are 27.78, 27.78, 27.78, 8.53, and 8.53, respectively.

Embodiment 3

[0040] The only difference between this implementation and Example 1 is that Ti a Zr b f c Nb d Ta e Among them, a, b, c, d, and e are 25, 25, 25, 12.5, and 12.5, respectively.

[0041] The alloy composition is shown in Table 1:

[0042] alloy Ti Zr f Nb Ta Ti 20 Zr 20 f 20 Nb 20 Ta 20

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com