Infiltration aiding agent for zinc, aluminum and magnesium mechanical energy infiltration aiding and use method for infiltration aiding agent

A penetration aid and mechanical energy technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of easy oxidation of metal surface, difficult surface activation and stable control, etc., to achieve uniform thickness, prevent secondary The effect of secondary oxidation and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

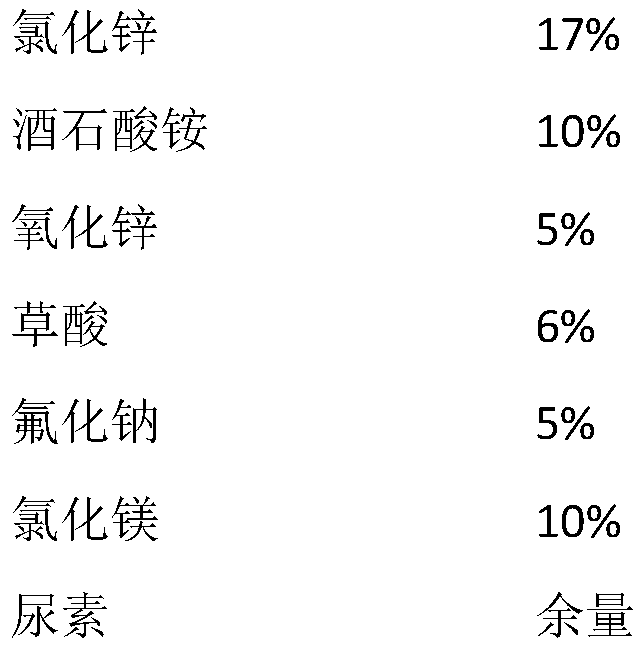

[0044] The composition and mass percent of the penetration aid described in the present embodiment are:

[0045]

[0046]When the permeation aid in this embodiment is used for the mechanical energy permeation aid treatment of iron and steel parts: the above-mentioned raw materials are weighed and mixed according to the mass percentage to prepare 7.5 kg, and 25 kg of zinc-6% aluminum-4% magnesium alloy powder, appropriate amount of corundum powder, 2500kg of M20 bolts are loaded into the heat infiltration furnace together, and then the heat infiltration furnace is closed and rotated, and the heat infiltration treatment is completed after 400°C + 5 hours; the bolts are separated by unloading after cooling, the separated corundum powder is gray, and the surface of the bolts is uniform Grey, there is no debris on the surface of the bolt and the bottom of the thread. After shot blasting, the surface of the bolt is uniform off-white. The metallographic method of the cross section ...

Embodiment 2

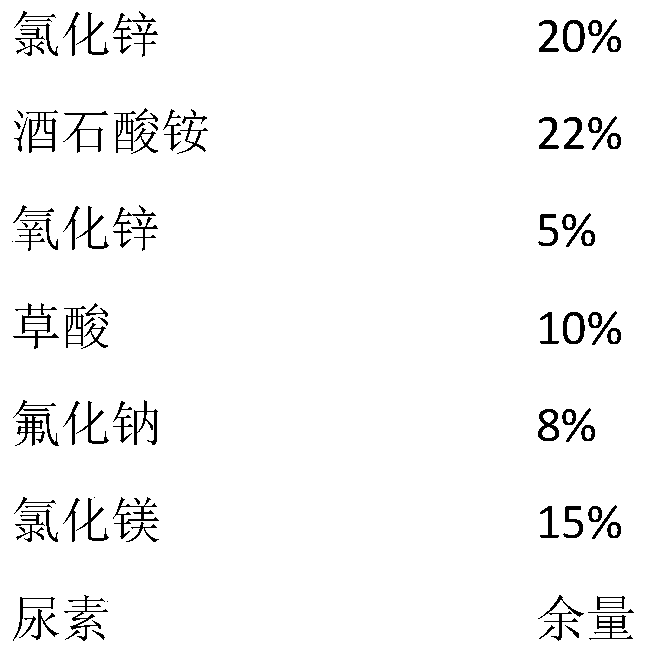

[0048] The composition and mass percent of the penetration aid described in the present embodiment are:

[0049]

[0050] When the permeation aid in this embodiment is used in the mechanical energy permeation aid treatment of iron and steel parts: the above-mentioned raw materials are weighed and mixed according to the mass percentage to prepare 2.5 kg evenly, and 25 kg of zinc-6% aluminum-4% magnesium alloy powder, appropriate amount of corundum powder, 2500kg of M16 bolts are loaded into the heat seepage furnace together, and then the heat seepage furnace is closed and rotated, and the heat seepage treatment is completed after 400°C + 4.5 hours; after cooling, the bolts are separated by unloading, the separated corundum powder is gray, and the surface of the bolts is uniform Grey, there is no debris on the surface of the bolt and the bottom of the thread. After shot blasting, the surface of the bolt is uniformly light gray. The metallographic method of the cross section sh...

Embodiment 3

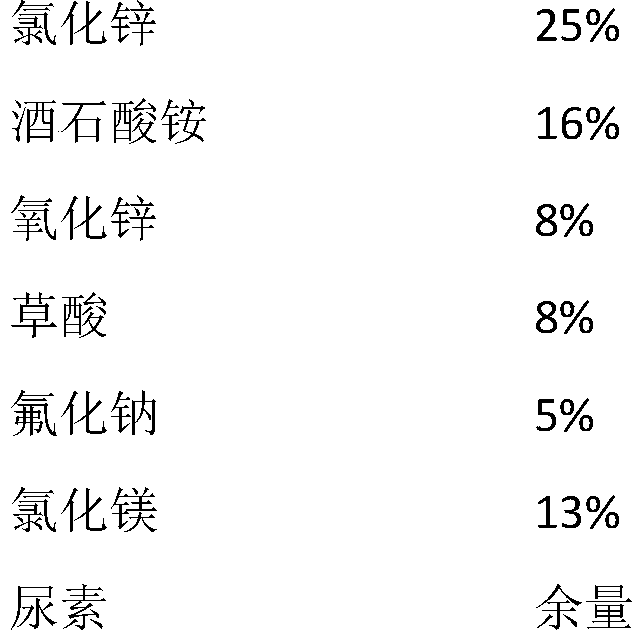

[0052] The composition and mass percent of the penetration aid described in the present embodiment are:

[0053]

[0054] When the permeation aid in this example is used for the mechanical energy permeation aid treatment of iron and steel parts: weigh and mix the above-mentioned raw materials according to the mass percentage to prepare 12 kg, and mix with 60 kg of zinc-6% aluminum-4% magnesium alloy powder, appropriate amount of corundum powder, M20 4000kg of bolts are loaded together into the heat seepage furnace, and then the heat seepage furnace is closed and rotated, and the heat seepage treatment is completed after 400°C + 6 hours; after cooling, the bolts are separated by unloading, and the surface of the bolts is uniform gray, and the surface of the bolts and the bottom of the thread There is no adhesion and adhesion of sundries, and the surface of the bolt after shot blasting is uniform off-white. The metallographic method of the cross section shows that the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com