Laser cladding coating for improving water erosion resistance of brazed stellite and preparation method

A laser cladding and coating technology, applied in the direction of metal material coating process and coating, to prevent carbonization and hardening, improve water corrosion resistance, and eliminate stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

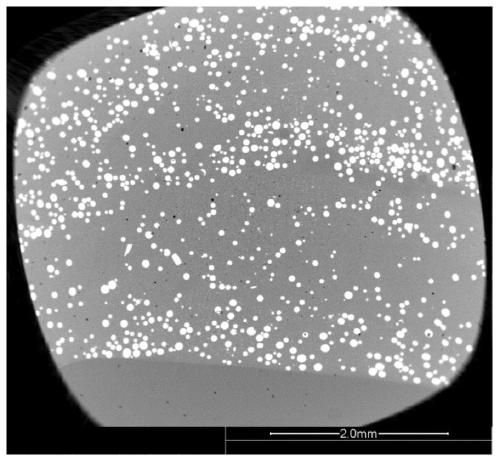

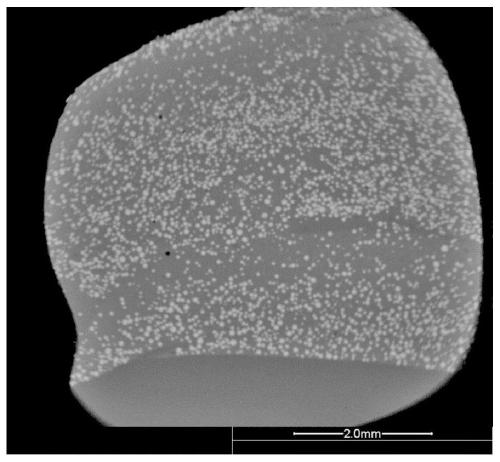

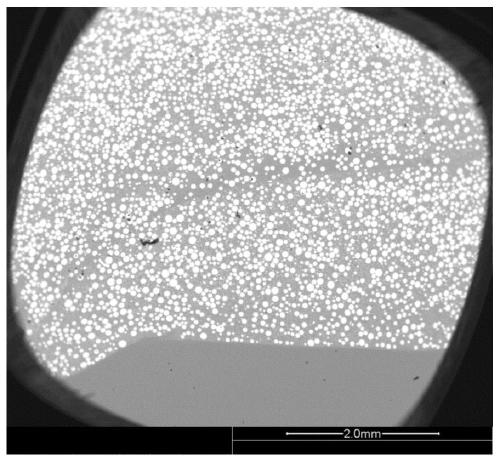

Image

Examples

Embodiment 1

[0028] (1) Select Ni625 powder with a particle size of 5m~30m and spherical WC particles with a particle size of 5m~125m, mix them uniformly and dry them at 120°C for 0.5h. Degree 1-1.5, WC particles account for 30wt% of the total mass of Ni625 powder and WC particles;

[0029] (2) Utilize acetone solution to clean the pollutants on the surface of the Stellite alloy substrate, and carry out sandblasting treatment on the surface of the Stellite alloy substrate. Clean and dry, clamp the Stellite alloy substrate on the mobile platform;

[0030] (3) Laser cladding uses Trumpf Trulaser 4006 laser for cladding. During the laser cladding process, the light output power is 1000W, the spot diameter is 5mm, the overlap is 4mm, and the laser scanning speed is 800mm / min;

[0031] (4) The powder spreading speed is 800mm / min, the powder spreading amount is 2g / min, the cooling gas flow rate is 10L / min, and the cleaning gas flow rate is 5L / min;

[0032] (5) The mixed powder is sent into the...

Embodiment 2

[0035] (1) Select 25% NiCr-Cr with a particle size of 30m ~ 80m 2 C 3 The powder and spherical WC particles with a particle size of 5m~125m are evenly mixed and dried at 100°C for 1h. Among them, the thickness of tungsten oxide on the surface of WC particles is 0.05m~1m, the ellipticity is 1~1.5, and the mass of WC particles accounts for the mass of Ni625 powder and WC 45% by weight of the total mass of the particles;

[0036] (2) Utilize acetone solution to clean the pollutants on the surface of the Stellite alloy substrate, and carry out sandblasting treatment on the surface of the Stellite alloy substrate. Clean and dry, clamp the Stellite alloy substrate on the mobile platform;

[0037] (3) Laser cladding adopts Trumpf Trulaser 4006 laser for cladding. During the laser cladding process, the light output power is 2500W, the spot diameter is 3mm, the overlapping amount is 2mm, and the laser scanning speed is 500mm / min;

[0038](4) The powder spreading speed is 500mm / min, ...

Embodiment 3

[0042] (1) Select NiCrBSi powder with a particle size of 80m~125m and spherical WC particles with a particle size of 5m~125m, mix them uniformly and dry them at 80°C for 2 hours, wherein the thickness of tungsten oxide on the surface of WC particles is 0.05m~1m, 1~1.5, the mass of WC particles accounts for 60wt% of the total mass of Ni625 powder and WC particles;

[0043] (2) Utilize acetone solution to clean the pollutants on the surface of the Stellite alloy substrate, and carry out sandblasting treatment on the surface of the Stellite alloy substrate. After sandblasting, the roughness of the Stellite alloy substrate is 10 μm. Clean and dry, clamp the Stellite alloy substrate on the mobile platform;

[0044] (3) Laser cladding adopts Trumpf Trulaser 4006 laser for cladding. During the laser cladding process, the light output power is 5000W, the spot diameter is 1mm, the overlapping amount is 1mm, and the laser scanning speed is 100mm / min;

[0045] (4) The powder spreading s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com