A kind of preparation method of superhydrophobic coating

A super-hydrophobic coating, ionized water technology, applied in the coating, the device for coating liquid on the surface, the surface pretreatment, etc. Cracks or fractures, etc., to achieve the effect of increasing hydrophobicity, low surface energy, and stable coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of superhydrophobic coating of the present embodiment, described method comprises the steps:

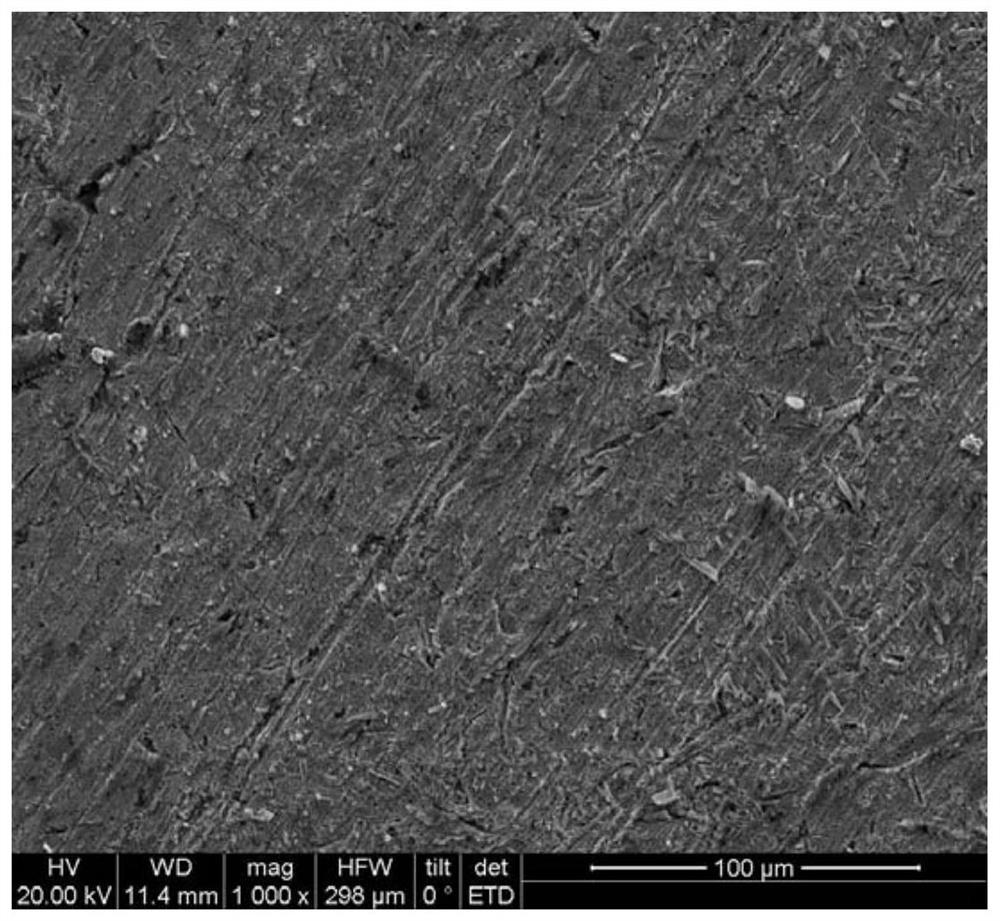

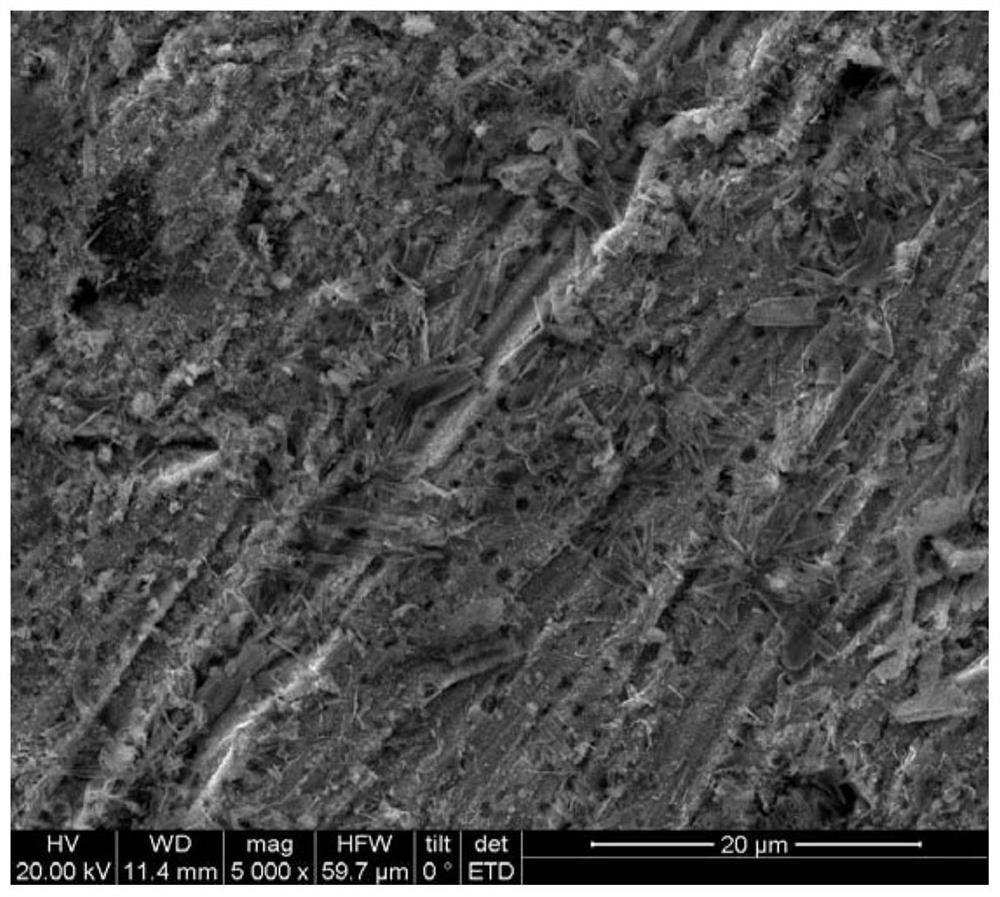

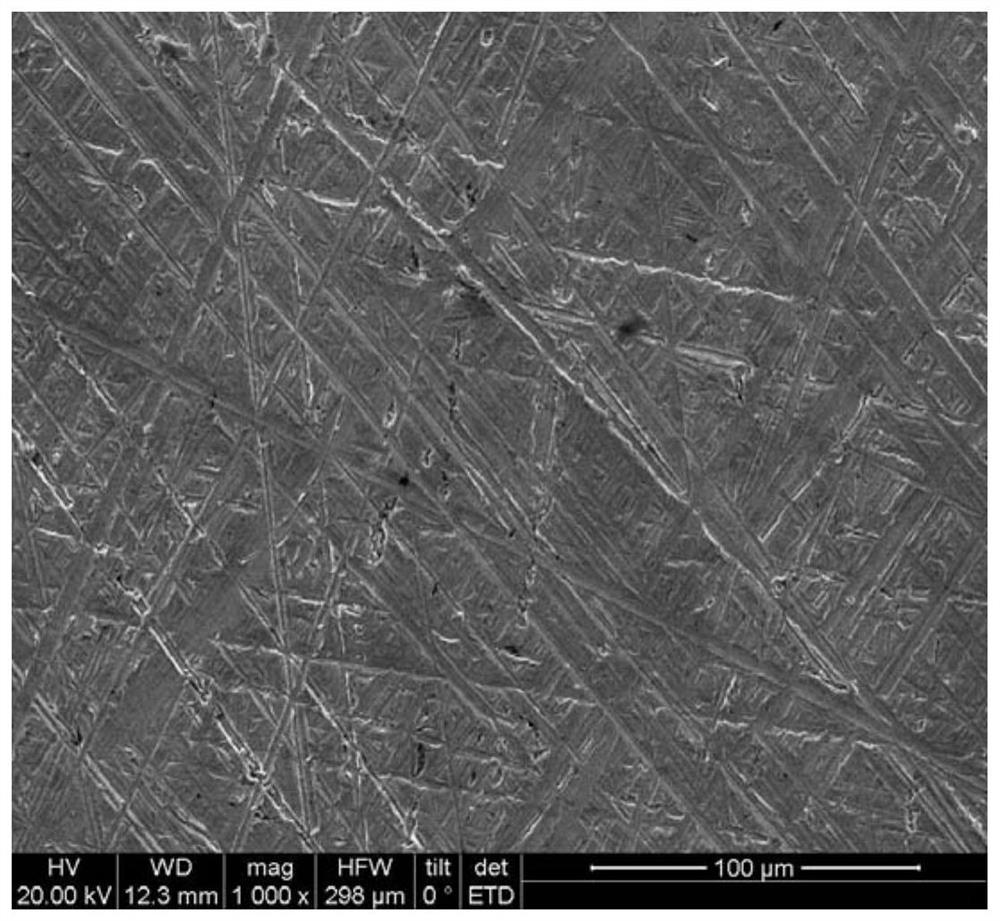

[0041] (1) Substrate pretreatment: select a circular copper sheet with a diameter of 1 cm and a thickness of 0.2 mm, and polish and derust the surface of the copper sheet sequentially through 400 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 2000 mesh sandpaper, and then Use acetone, ethanol, and deionized water to ultrasonically clean surface oil stains and other impurities, and dry them for later use;

[0042](2) Copper sheet etching: first copper sheet is immersed in the mixed solution of sodium chloride and hydrochloric acid 4h, and the mixed solution of sodium chloride and hydrochloric acid is the sodium chloride aqueous solution that concentration is 1mol / L and mass fraction is 10% hydrochloric acid The solutions are mixed in equal volumes, cleaned with deionized water, dried, and then immersed in the mixed solution of hydrogen peroxide and hydro...

Embodiment 2

[0045] A kind of preparation method of superhydrophobic coating of the present embodiment, described method comprises the steps:

[0046] (1) Substrate pretreatment: select a circular copper sheet with a diameter of 1 cm and a thickness of 0.2 mm, and polish and derust the surface of the copper sheet sequentially through 400 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 2000 mesh sandpaper, and then Use acetone, ethanol, and deionized water to ultrasonically clean surface oil stains and other impurities, and dry them for later use;

[0047] (2) Copper sheet etching: earlier copper sheet is immersed in the mixed solution of sodium chloride and hydrochloric acid 6h, and the mixed solution of sodium chloride and hydrochloric acid is the sodium chloride aqueous solution that concentration is 1.5mol / L and mass fraction is 15% Hydrochloric acid solution is mixed in equal volumes, cleaned with deionized water, dried, and then immersed in a mixed solution of hydrogen peroxide and hydrochl...

Embodiment 3

[0050] A kind of preparation method of superhydrophobic coating of the present embodiment, described method comprises the steps:

[0051] (1) Substrate pretreatment: select a circular copper sheet with a diameter of 1 cm and a thickness of 0.2 mm, and polish and derust the surface of the copper sheet sequentially through 400 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 2000 mesh sandpaper, and then Use acetone, ethanol, and deionized water to ultrasonically clean surface oil stains and other impurities, and dry them for later use;

[0052] (2) Copper sheet etching: first copper sheet is immersed in the mixed solution of sodium chloride and hydrochloric acid 8h, and the mixed solution of sodium chloride and hydrochloric acid is the sodium chloride aqueous solution that concentration is 2mol / L and mass fraction is 20% hydrochloric acid The solution is mixed in equal volumes, dried, and then immersed in the mixed solution of hydrogen peroxide and hydrochloric acid for 10 hours. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com