Panel widening equipment and process for wide-width composite panels

A composite board and panel technology, which is applied in thin material processing, chemical instruments and methods, lamination, etc., can solve the problems of inability to flexibly control the width of products, inability to manufacture composite panels, and inability to weld and process, so as to facilitate storage and transportation. , Improve the quality of processing, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

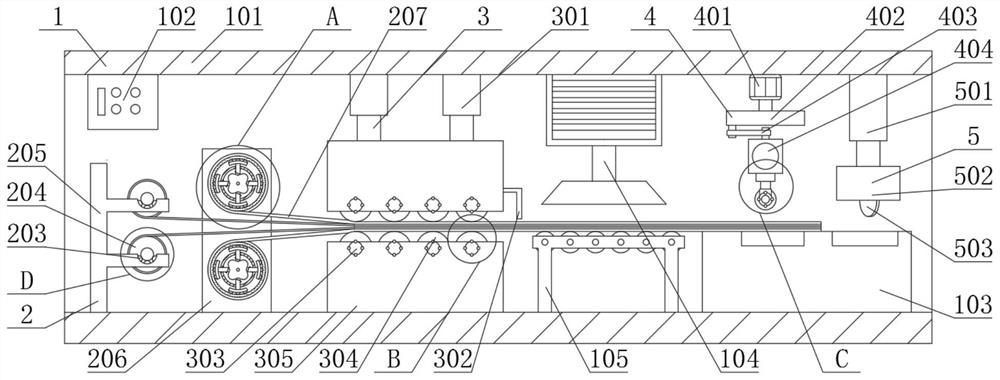

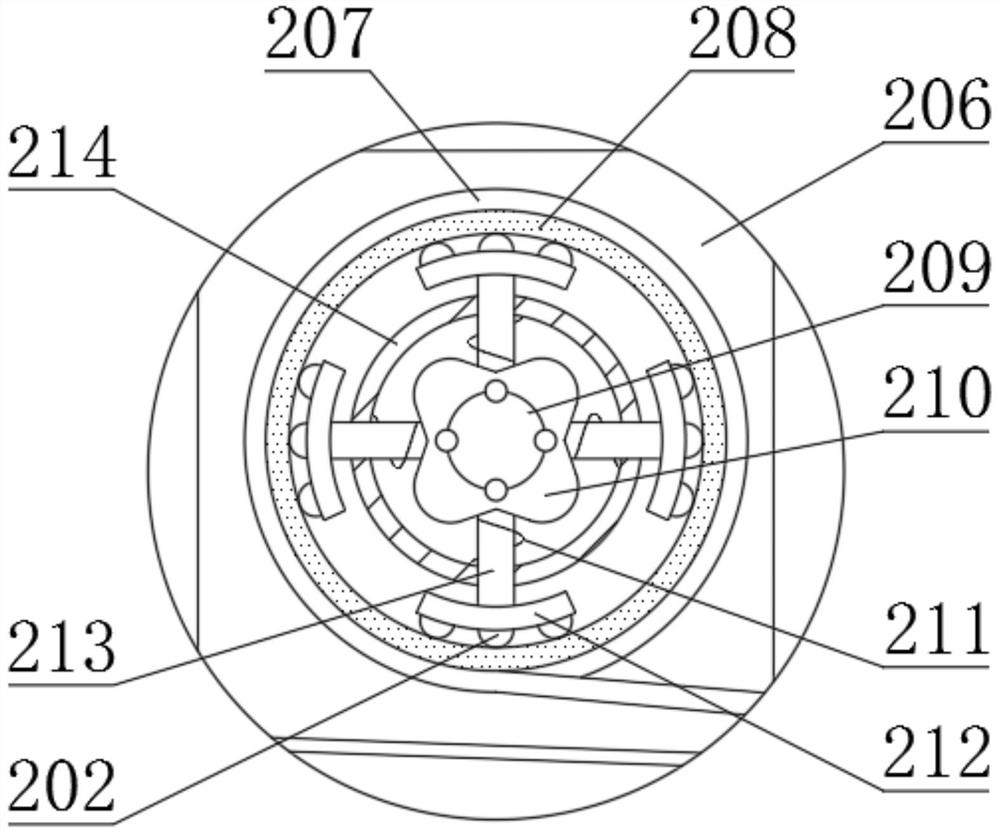

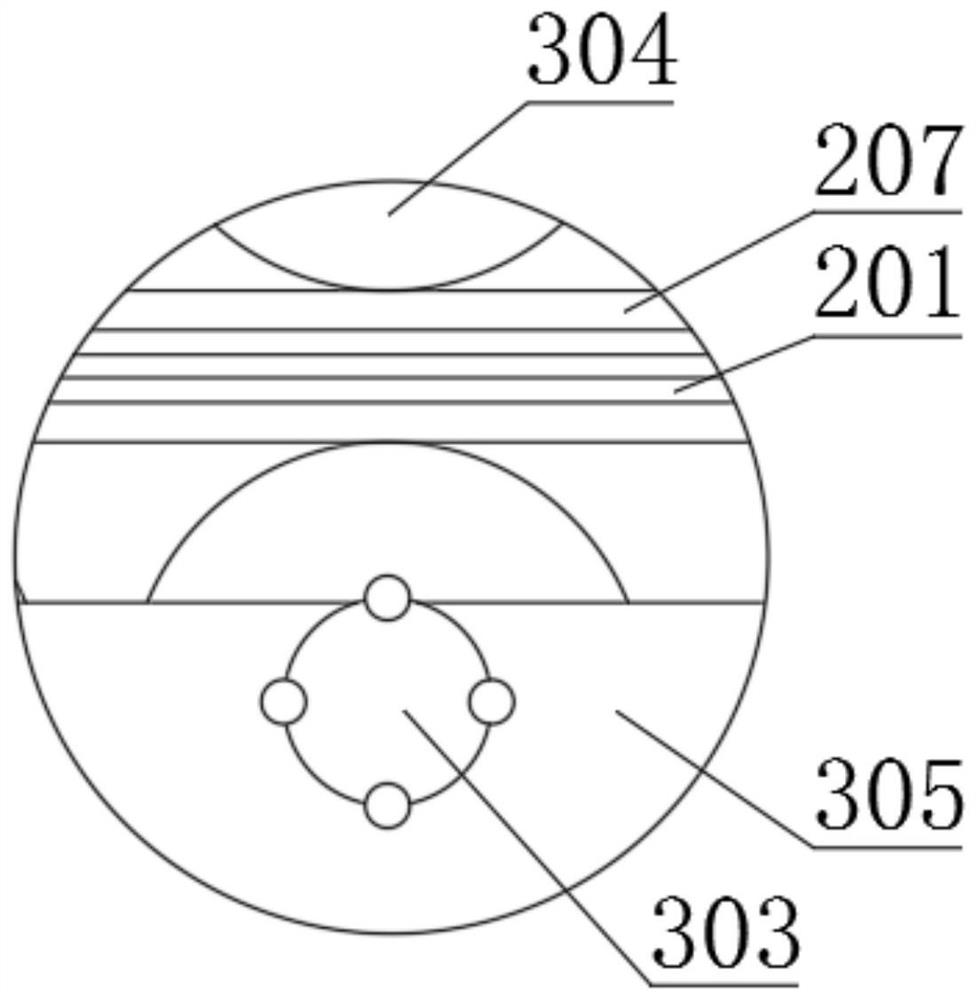

[0032] see Figure 1-8 , the present invention provides a technical solution:

[0033]A panel widening equipment for a wide-width composite panel and its process, including a main device 1, a placing device 2, a composite device 3, a longitudinal cutting device 4 and a transverse cutting device 5, one end of the main device 1 is fixedly connected to the placing device 2, The right side of the placement device 2 is provided with a composite device 3, and the composite device 3 is fixedly connected with the main device 1, the inner side of the main device 1 is fixedly connected with a longitudinal cutting device 4, and the right side of the longitudinal cutting device 4 is provided with a transverse cutting device 5, And the transverse cutting device 5 is fixedly connected with the main device 1, the main device 1 includes a fixed seat 101 and a control cabinet 102, a cutting table 103, an air conditioner 104, a roller conveyor 105, a door panel 106 and a handle 107, and one end...

Embodiment 2

[0041] see Figure 1-8 , the present invention provides a technical solution:

[0042]A panel widening equipment for a wide-width composite panel and its process, including a main device 1, a placing device 2, a composite device 3, a longitudinal cutting device 4 and a transverse cutting device 5, one end of the main device 1 is fixedly connected to the placing device 2, The right side of the placement device 2 is provided with a composite device 3, and the composite device 3 is fixedly connected with the main device 1, the inner side of the main device 1 is fixedly connected with a longitudinal cutting device 4, and the right side of the longitudinal cutting device 4 is provided with a transverse cutting device 5, And the transverse cutting device 5 is fixedly connected with the main device 1, the main device 1 includes a fixed seat 101 and a control cabinet 102, a cutting table 103, an air conditioner 104, a roller conveyor 105, a door panel 106 and a handle 107, and one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com