Granular biological organic fertilizer

A bio-organic fertilizer and granule technology, which is applied in the direction of phosphate fertilizer, fertilization device, fertilizer mixture, etc., can solve the problems of restricting the popularization and application of granule bio-organic fertilizer, the influence of unfavorable survival factors, and the difficulty in achieving the expected fertilizer effect, so as to achieve favorable adhesion and Effects of fixing, promoting rapid growth, improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

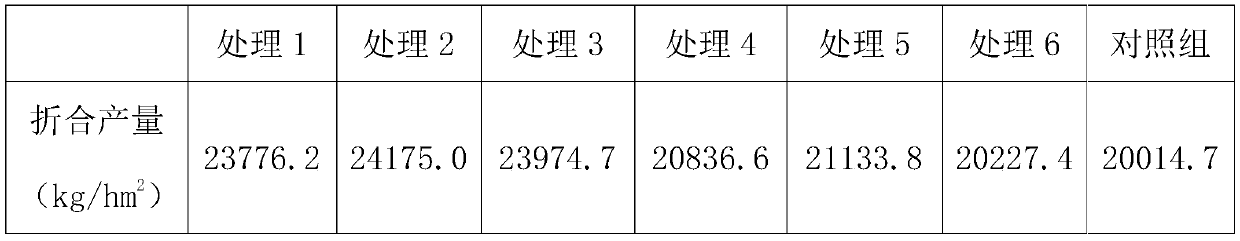

Examples

Embodiment 1

[0024] A kind of granular bio-organic fertilizer, comprising the following raw materials in parts by weight:

[0025] Decomposed organic material 400, inorganic fertilizer 100, inorganic clay 40, humic acid 20, porous starch 20, puffed feather powder 20, activated sludge 10, microbial powder 5, coating binder 1;

[0026] The total effective number of viable bacteria in the microbial powder is 0.2×10 8 cfu / g.

Embodiment 2

[0028] A kind of granular bio-organic fertilizer, comprising the following raw materials in parts by weight:

[0029] Decomposed straw 400, inorganic fertilizer 100, attapulgite 40, humic acid 20, porous starch 20, puffed feather powder 20, activated sludge 10, microbial powder 5, polyvinyl alcohol 1;

[0030] The total effective number of viable bacteria in the microbial powder is 0.2×10 8 cfu / g.

[0031] The inorganic fertilizer is made by mixing urea, monoammonium phosphate and potassium sulfate at a weight ratio of 1:0.4:0.3.

[0032] The preparation method of the porous starch is as follows: enzymatically hydrolyze corn starch with α-amylase and glucoamylase for 20 hours at a pH of 5 and a temperature of 40° C., wherein the weight ratio of α-amylase to glucoamylase is 1:0.3.

[0033] The preparation method of puffed feather powder is as follows: adding water to the chicken feather powder to make the water content of the chicken feather powder 15%, then using a screw ext...

Embodiment 3

[0042] A kind of granular bio-organic fertilizer, comprising the following raw materials in parts by weight:

[0043] Decomposed straw 450, inorganic fertilizer 120, bentonite 50, humic acid 25, porous starch 30, puffed feather powder 30, activated sludge 15, microbial powder 8, polyvinyl alcohol 2;

[0044] The total effective number of viable bacteria in the microbial powder is 0.25×10 8 cfu / g.

[0045] The inorganic fertilizer is made by mixing urea, monoammonium phosphate and potassium sulfate at a weight ratio of 1:0.6:0.6.

[0046] The preparation method of the porous starch is as follows: enzymatically hydrolyze corn starch with α-amylase and glucoamylase for 20 hours at a pH of 5 and a temperature of 40° C., wherein the weight ratio of α-amylase to glucoamylase is 1:2.

[0047] The preparation method of puffed feather powder is: add water conditioning to chicken feather powder, make the water content of chicken feather powder be 20%, then carry out heating extrusion pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com