N-methyl-4-nitrophthalimide preparation method

A technology of nitrophthalimide and methylphthalimide, which is applied in the field of preparation of N-methyl-4-nitrophthalimide, can solve the problem of equipment and Operational hazards, low yield, environmental pollution and other problems, to avoid environmental and human hazards, improve yield and purity, and promote the effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

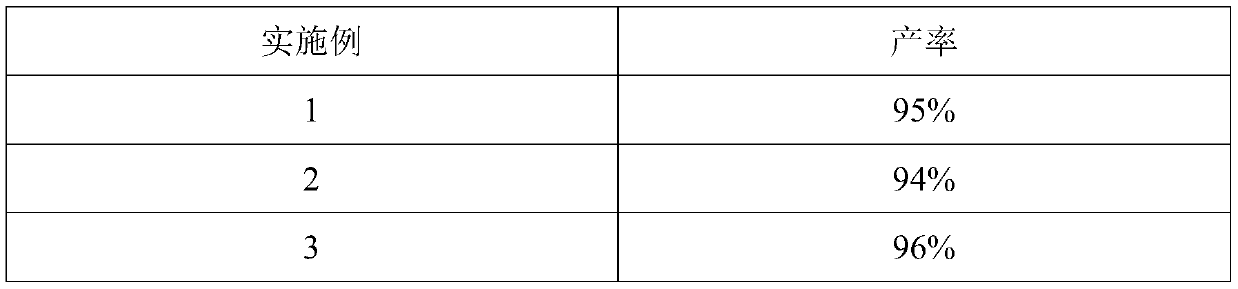

Embodiment 1

[0072] Embodiment 1 of the present invention provides a kind of preparation method of N-methyl-4-nitrophthalimide, comprises the following steps:

[0073] Preparation of nitrating agent: mix potassium nitrate and concentrated sulfuric acid at 0°C, and the molar ratio of ammonium nitrate and concentrated sulfuric acid is 1:1.8 to generate nitrating agent;

[0074] Preparation of N-methylphthalimide: add methylamine-ethanol solution and phthalic anhydride to toluene, the molar ratio of methylamine and phthalic anhydride is 1:1, heat to reflux for 3 hours, dry, and crystallize by ethanol cooling to obtain N-methylphthalimide;

[0075] Preparation of N-methyl-4-nitrophthalimide: add nitrating agent to N-methylphthalimide at -5°C, react at 40°C for 4 hours, and extract with extraction solvent, Drying produces N-methyl-4-nitrophthalimide.

[0076] The extraction solvent is ethyl acetate and dichloromethane in a weight ratio of 1:0.6, and the weight ratio of the extraction solvent ...

Embodiment 2

[0078] Embodiment 1 of the present invention provides a kind of preparation method of N-methyl-4-nitrophthalimide, comprises the following steps:

[0079] Preparation of nitrating agent: mix magnesium nitrate and concentrated sulfuric acid at 10°C, and the molar ratio of potassium nitrate and concentrated sulfuric acid is 1:2.2 to generate nitrating agent;

[0080] Preparation of N-methylphthalimide: add methylamine-ethanol solution and phthalic anhydride to toluene, the molar ratio of methylamine and phthalic anhydride is 2:1, heat to reflux for 2h, dry, and crystallize by ethanol cooling to obtain N-methylphthalimide;

[0081] Preparation of N-methyl-4-nitrophthalimide: Add nitrating agent to N-methylphthalimide at 5°C, react at 50°C for 3h, extract with extraction solvent, and dry , Generate N-methyl-4-nitrophthalimide.

[0082] The extraction solvent is ethyl acetate and dichloromethane in a weight ratio of 1:0.8, and the weight ratio of the extraction solvent to N-methy...

Embodiment 3

[0084] Embodiment 3 of the present invention provides a kind of preparation method of N-methyl-4-nitrophthalimide, comprises the following steps:

[0085] Preparation of nitrating agent: mix ammonium nitrate and concentrated sulfuric acid at 5°C, the molar ratio of ammonium nitrate and concentrated sulfuric acid is 1:2, and generate nitrating agent;

[0086] Preparation of N-methylphthalimide: add methylamine-ethanol solution and phthalic anhydride to toluene, the molar ratio of methylamine and phthalic anhydride is 1.5:1, heat to reflux for 2.5h, dry, and ethanol cooling crystallization, Obtain N-methylphthalimide;

[0087] Preparation of N-methyl-4-nitrophthalimide: Add nitrating agent to N-methylphthalimide at 0°C, react at 45°C for 3.5h, and extract with extraction solvent, Drying produces N-methyl-4-nitrophthalimide.

[0088] The extraction solvent is ethyl acetate and dichloromethane in a weight ratio of 1:0.7, and the weight ratio of the extraction solvent to N-methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com