Nanocellulose-based airgel based on electrostatic adsorption and chemical crosslinking enhancement and its preparation method

A technology of nanocellulose and chemical cross-linking, which is applied in the field of nanocellulose-based airgel and its preparation, can solve problems such as poor compatibility, easy aggregation of inorganic nanoparticles, and destruction of the airgel skeleton structure, and achieve improved stability Sexuality, low price, great potential for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

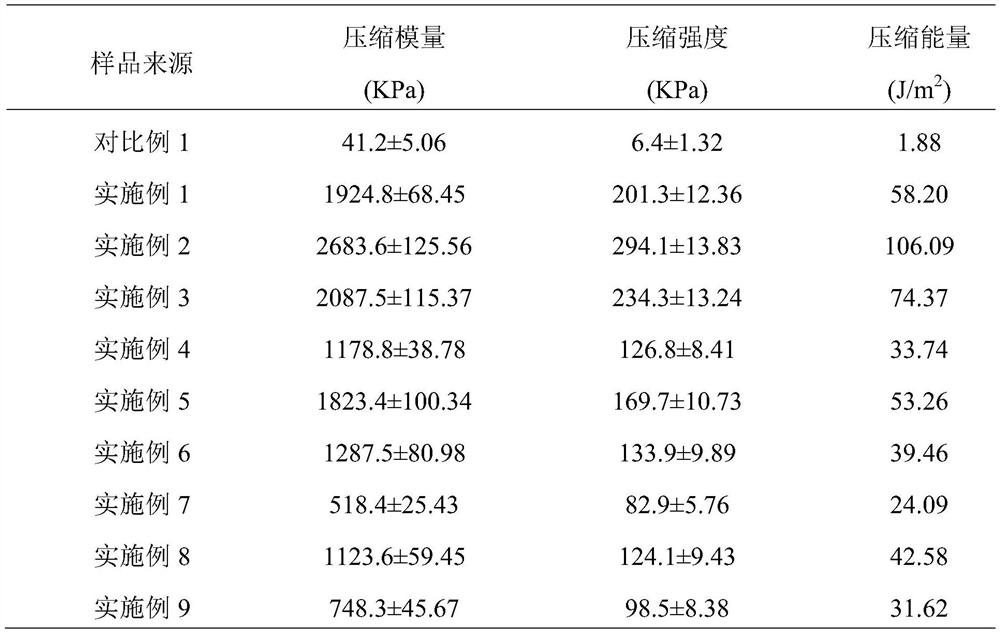

Examples

Embodiment 1

[0028] At room temperature, 25 g of cationized cellulose nanocrystal suspension (1% by mass fraction), 75 g of cellulose nanocrystal microfibril suspension (1% by mass fraction), and 0.6 g of sodium alginate solid were mixed, and the resulting mixture was strongly mechanically After stirring for 3 hours, a well mixed suspension was obtained. The suspension was dried for 48 hours by freeze drying or supercritical carbon dioxide drying to obtain 1.6 g of composite airgel.

[0029] Weigh 4g HT, 0.12g trimethylamine, and 50g acetone to prepare a cross-linking solution, immerse 1.6g composite airgel in the cross-linking solution and react at 30°C for 48 hours, then wash repeatedly with acetone solution to remove the aerogel The unreacted cross-linking reagent on the surface is finally freeze-dried or supercritical carbon dioxide dried to obtain the target composite airgel product.

Embodiment 2

[0031] This example is basically the same as Example 1, except that the dosages of the cellulose nanocrystal suspension and the cellulose nanofiber suspension are changed from 25g and 75g to 50g and 50g respectively.

Embodiment 3

[0033] This example is basically the same as Example 1, except that the dosages of the cellulose nanocrystal suspension and the cellulose nanofiber suspension are changed from 25g and 75g to 75g and 25g respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com