A kind of reaction double viscous polymer waterproof membrane and its production method

A technology of polymer waterproofing and production methods, applied in the direction of non-polymer adhesive additives, adhesive types, adhesives, etc., can solve the problem of poor bonding between reactive adhesive waterproofing membranes and base layers, and leaving modified asphalt materials , affect the waterproof effect and other issues, to achieve the effect of ensuring the waterproof sealing effect, improving the initial viscosity, and ensuring the sealing and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

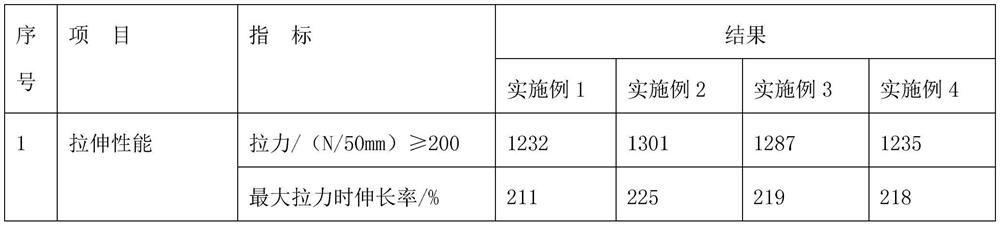

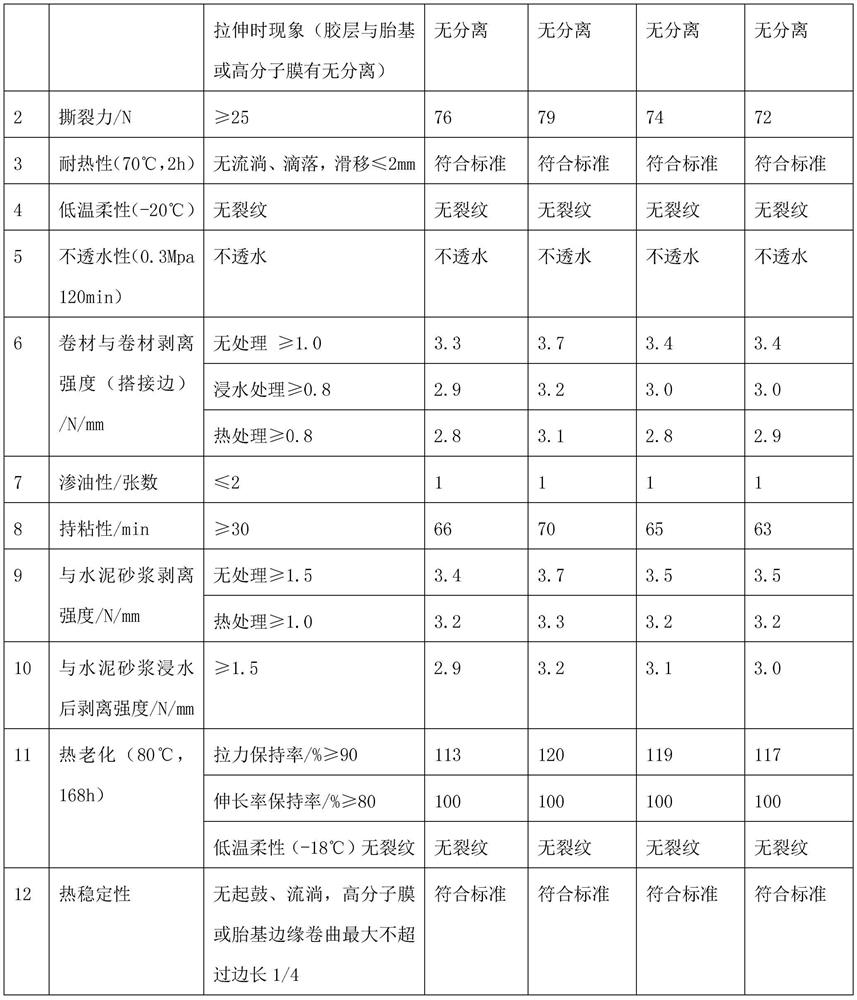

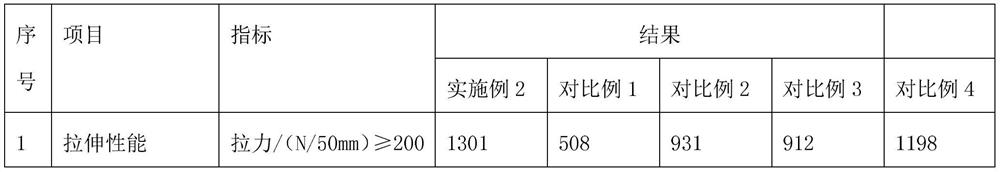

Examples

Embodiment 1

[0030] A reactive double sticky polymer waterproofing membrane, coated with reactive sticky modified asphalt reactive viscose on both sides of the high-strength polyolefin thermoplastic elastomer tire base reinforcement layer by oiling counter-rollers to form a modified asphalt reactive adhesive The adhesive layer is then covered with an anti-adhesive release film on the modified asphalt reactive adhesive layer:

[0031] The modified asphalt reaction viscose is made of the following raw materials in parts by weight: 45 parts of 90# petroleum asphalt, 4 parts of polystyrene-butadiene copolymer with an average molecular weight of 150,000, styrene-isobutadiene copolymer with an average molecular weight of 80,000 3 parts of pentadiene-styrene block copolymer, 2 parts of epoxy resin powder, 8 parts of naphthenic rubber oil, 3 parts of reactive tackifying resin, 3 parts of plasticizer trimellitate, antioxidant phosphorous acid 0.5 part of tris(2,4-di-tert-butylphenyl) ester, 0.8 par...

Embodiment 2

[0041] A reactive double sticky polymer waterproofing membrane, coated with reactive sticky modified asphalt reactive viscose on both sides of the high-strength polyolefin thermoplastic elastomer tire base reinforcement layer by oiling counter-rollers to form a modified asphalt reactive adhesive The adhesive layer is then covered with an anti-adhesive release film on the modified asphalt reactive adhesive layer:

[0042] The modified asphalt reaction viscose is made of the following raw materials in parts by weight: 60 parts of 90# petroleum asphalt, 6 parts of polystyrene butadiene copolymer with an average molecular weight of 180,000, and styrene-isoamyl copolymer with an average molecular weight of 100,000 5 parts of diene-styrene block copolymer, 4 parts of epoxy resin powder, 10 parts of naphthenic rubber oil, 5 parts of active tackifying resin, 4 parts of plasticizer trimellitate, antioxidant triphosphite 0.8 part of (2,4-di-tert-butylphenyl) ester, 1 part of vinyl tris ...

Embodiment 3

[0052] A reactive double sticky polymer waterproofing membrane, coated with reactive sticky modified asphalt reactive viscose on both sides of the high-strength polyolefin thermoplastic elastomer tire base reinforcement layer by oiling counter-rollers to form a modified asphalt reactive adhesive The adhesive layer is then covered with an anti-adhesive release film on the modified asphalt reactive adhesive layer:

[0053] The modified asphalt reaction viscose is made of the following raw materials in parts by weight: 65 parts of 90# petroleum asphalt, 8 parts of polystyrene butadiene copolymer with an average molecular weight of 200,000, and styrene-isoamyl copolymer with an average molecular weight of 120,000. 6 parts of diene-styrene block copolymer, 5 parts of epoxy resin powder, 12 parts of naphthenic rubber oil, 6 parts of active tackifying resin, 5 parts of plasticizer trimellitate, antioxidant triphosphite 1 part of (2,4-di-tert-butylphenyl) ester, 2 parts of cross-linki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com