Construction and application of an engineered strain of Escherichia coli producing n-butyric acid

A genetically engineered bacteria and genetic engineering technology, applied in the direction of bacteria, microorganism-based methods, lytic enzymes, etc., to achieve the effects of low production cost, short fermentation cycle, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

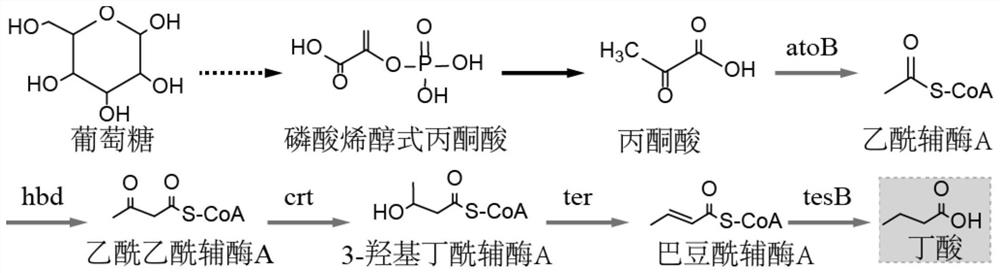

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1E

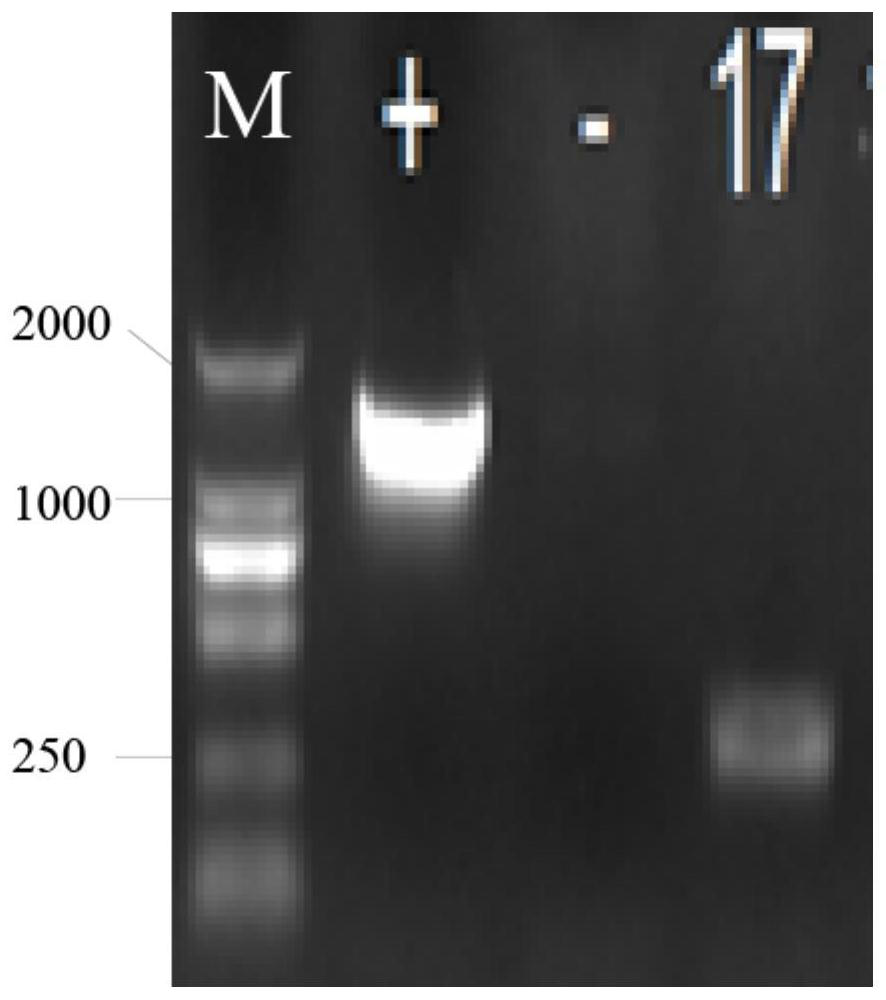

[0056] The knockout of embodiment 1E.coli ATCC8739 acetate kinase gene ackA

[0057] According to the 45 bp sequence of the 5' and 3' ends of the ackA (acetate kinase gene) gene in Escherichia coli ATCC8739 in the NCBI database, the upper and lower homology arm amplification primers ackA-1 and ackA-2 were designed and amplified using pKD4 as a template A knockout frame containing a homology arm was produced and named ackAK.

[0058] The ackAK was electrotransformed into E.coli ATCC8739 competent cells containing the pKD46 plasmid (electric transformation voltage and time were 2500V and 5mS, respectively). Quickly recover in 1 mL LB medium at 37°C and 150 rpm for 1 hour, and spread on LB solid medium plate containing kanamycin (30 g / mL). After 24 hours of inverted culture, positive transformants were identified by colony PCR using the identification primers ackA-U and ackA-D. The amplified fragment of the colony with the kanamycin resistance gene knockout frame successfully in...

Embodiment 2E

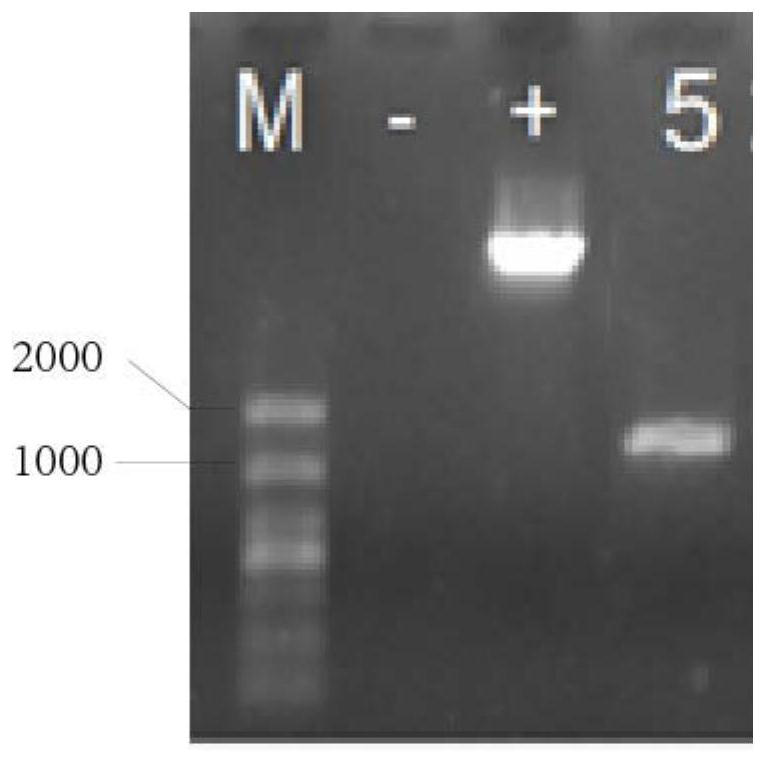

[0064] Example 2 Knockout of E.coli ATCC8739A Alcohol Dehydrogenase Gene adhE

[0065] According to the 45 bp sequence of the 5' and 3' ends of the adhE (alcohol dehydrogenase gene) gene in Escherichia coli ATCC8739 in the NCBI database, the upper and lower homology arm amplification primers adhE-1 and adhE-2 were designed, and pKD4 was used as a template A knockout box containing homology arms was amplified and named adhEK.

[0066] The adhEK was electrotransformed into E.coli ATCC8739A competent cells containing the pKD46 plasmid (electric transformation voltage and time were 2500V and 5ms, respectively). Quickly recover in 1 mL LB medium at 37°C and 150 rpm for 1 hour, and spread on LB solid medium plate containing kanamycin (30 g / mL). After 24 hours of inverted culture, positive transformants were identified by colony PCR using the identification primers adhE-U and adhE-D, and the amplified fragment of the colony where the kanamycin resistance gene knockout frame was succ...

Embodiment 3E

[0069] Example 3 Knockout of E.coli ATCC8739AA lactate dehydrogenase gene ldhA

[0070] According to the 45 bp sequence at the 5' and 3' ends of the ldhA (lactate dehydrogenase gene) gene in Escherichia coli ATCC8739 in the NCBI database, the upper and lower homology arm amplification primers ldhA-1 and ldhA-2 were designed, and pKD4 was used as a template A knockout cassette containing homology arms was amplified and named ldhAK.

[0071] The adhEK was electrotransformed into E.coli ATCC 8739AA competent cells containing the pKD46 plasmid (the electroporation voltage and time were 2500V and 5ms, respectively). Quickly recover in 1 mL LB medium at 37°C and 150 rpm for 1 hour, and spread on LB solid medium plate containing kanamycin (30 g / mL). After upside-down culture for 24 hours, positive transformants were identified by colony PCR using identification primers ldhA-U and ldhA-D. The amplified fragment of the colony with the kanamycin resistance gene knockout frame successfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com