Pumpable tough concrete and application thereof in bridge deck continuous slab structure

A technology of concrete and toughness, which is applied in the field of pumpable ductile concrete and its application in the bridge deck continuous slab structure. To solve problems such as torsional deformation, achieve the effect of improving rheology and plasticity, strong resistance to temperature change, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

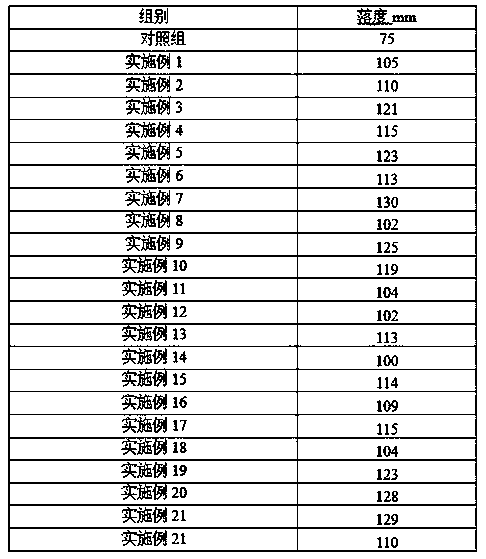

Embodiment 1

[0022] The invention is a kind of pumpable ductile concrete, which comprises the following components in parts by weight: 40.2 parts of cement, 4.0 parts of ceramic powder, 0.6 part of nano-calcium carbonate, 11.7 parts of plastic steel fiber, 0.3 part of polypropylene fiber, and 0.3 kg of glass fiber , 0.5 parts of water reducing agent melamine sulfonate formaldehyde condensate, 0.4 parts of calcium nitrate, 2.6 parts of silica fume, 13.4 parts of fly ash, 56.0 parts of gravel, 70 parts of medium sand, and 22.6 parts of water.

[0023] The polypropylene fibers included a length of 11 mm and a diameter of 0.035 mm.

[0024] One is based on the application of a pumpable ductile concrete in the bridge deck continuous slab structure described above. The concrete is poured in the gap between adjacent simply supported beams and cured for 20 days.

Embodiment 2

[0026] The invention is a kind of pumpable ductile concrete, which comprises the following components in parts by weight: 57.6 kg of cement, 5.8 parts of ceramic powder, 1.2 parts of nano silicon dioxide, 19.5 parts of plastic steel fiber, 0.5 part of polypropylene fiber, and 0.5 part of glass fiber 0.9 parts of water reducing agent naphthalene sulfonate formaldehyde condensate, 0.6 parts of sodium sulfate, 3.4 parts of silica fume, 28.8 parts of fly ash, 72.5 kg of stones, 87.0 kg of medium sand, and 23.6 parts of water.

[0027] The polypropylene fiber comprises a length of 22 mm and a diameter of 0.045 mm.

[0028] One is based on the application of a pumpable ductile concrete in the bridge deck continuous slab structure described above. The concrete is poured in the gap between adjacent simply supported beams and cured for 26 days.

Embodiment 3

[0030] The invention is a kind of pumpable ductile concrete, which comprises the following components in parts by weight: 50 parts of cement, 5.5 parts of ceramic powder, 0.8 parts of nano-calcium carbonate, 15 parts of plastic steel fiber, 2.5 kg of polypropylene fiber, and 2.5 parts of glass fiber , 0.6 parts of melamine sulfonate formaldehyde condensate, 0.5 parts of sodium nitrate, 3.0 parts of silica fume, 20.0 parts of fly ash, 60.0 parts of gravel, 75.0 parts of medium sand, and 26.8 parts of water.

[0031]The polypropylene fiber is a mixture of fibers with a length of 20mm and 11mm and a diameter of 0.04mm. . The particle size of the ceramic powder is 0.3 micron.

[0032] One is based on the application of a pumpable ductile concrete in the bridge deck continuous slab structure described above. The concrete is poured in the gap between adjacent simply supported beams and cured for 25 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com