Crystallization method of calcium gluconate

A technology of calcium gluconate and glucose, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve the problems of increasing operation time and easy generation of impurities, and achieve reduction of production energy consumption, The effect of shortening production time and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

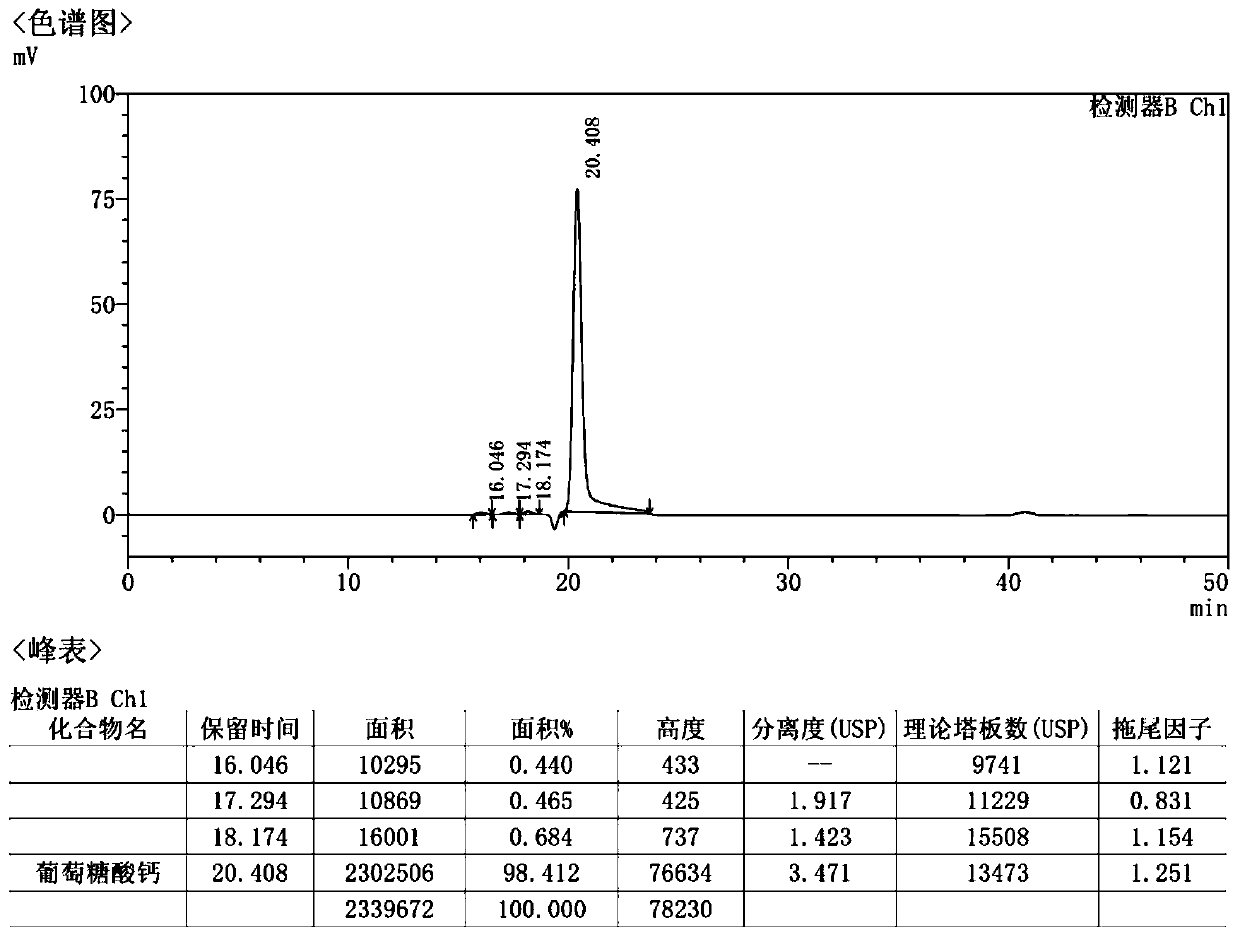

Embodiment 1

[0030] Put 20g of glucose into the reaction bottle, add 200mL of purified water and stir to dissolve, add 1.0g of palladium-carbon alloy Pd-Pt / C catalyst, control the temperature at 55±5°C, pass air into the reaction solution, and add calcium carbonate in batches to adjust pH to 7.0, and then pass air until the pH value of the reaction solution no longer drops.

[0031] Filter with a 0.45 μm filter, add 0.4 g of activated carbon, stir and decolorize at 70° C. for 1 hour, and filter with a 0.45 μm filter.

[0032] Measure the volume of the filtrate to be 132mL, add 70mL of methanol, cool to 10°C, heat and crystallize for 5 hours, filter, and dry the filter cake at 60°C to obtain 21.2g of calcium gluconate monohydrate, with a yield of 85.2% and a purity of 98.41%. .

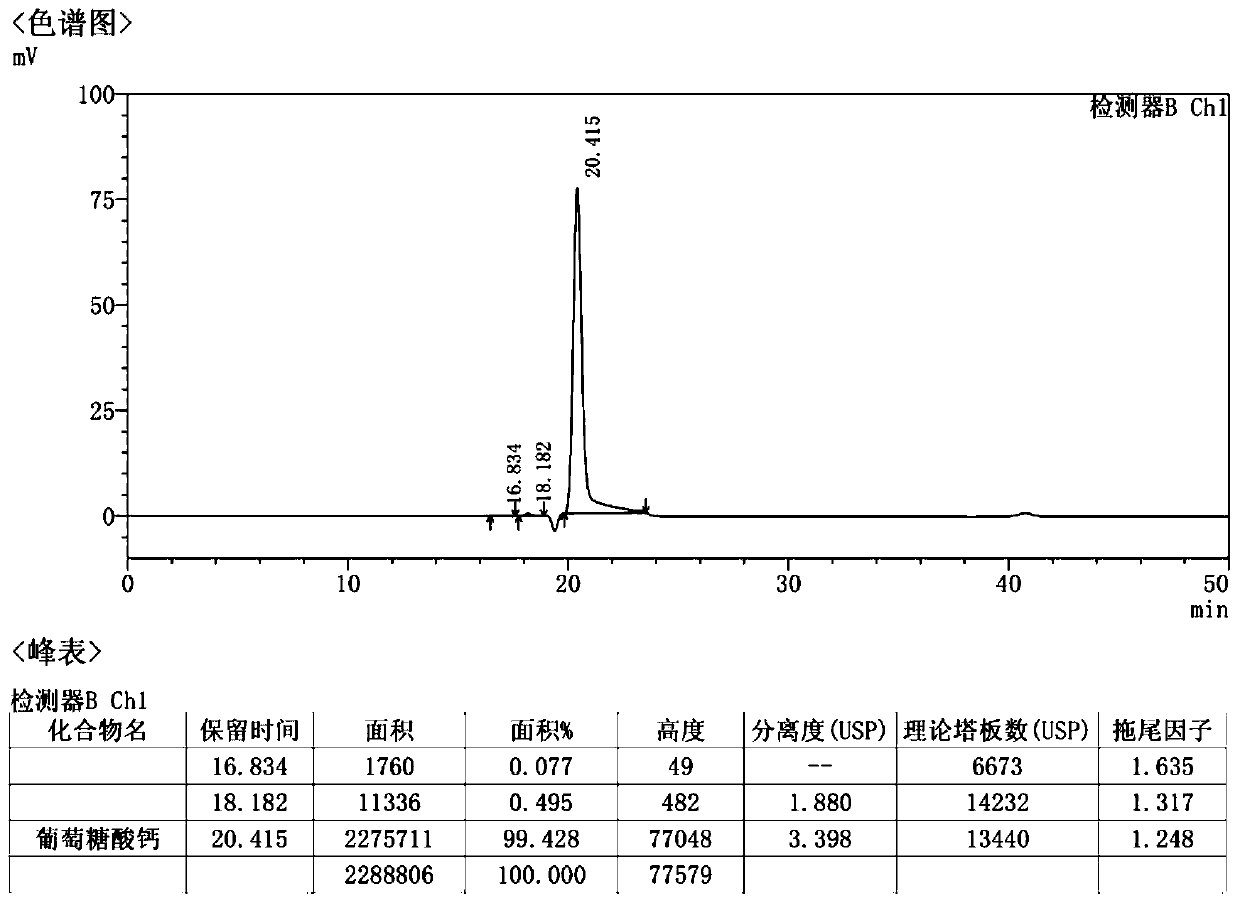

Embodiment 2

[0034] Put 20g of glucose into the reaction bottle, add 200mL of purified water and stir to dissolve, add 1.0g of palladium-carbon alloy Pd-Pt / C catalyst, control the temperature at 55±5°C, pass air into the reaction solution, and add calcium carbonate in batches to adjust pH to 7.0, and then pass air until the pH value of the reaction solution no longer drops.

[0035] Filter with a 0.45 μm filter, add 0.8 g of activated carbon, stir and decolorize at 70° C. for 1 hour, and filter with a 0.45 μm filter.

[0036] Measure the volume of the filtrate to be 170mL, add 150mL of absolute ethanol, cool to 20°C, heat and crystallize for 3 hours, filter, and dry the filter cake at 70°C to obtain 21.6g of calcium gluconate monohydrate, with a yield of 86.8%, a purity of 99.43%.

Embodiment 3

[0038] Put 50g of glucose into the reaction bottle, add 600mL of purified water and stir to dissolve, add 2.5g of palladium-carbon alloy Pd-Pt / C catalyst, control the temperature at 55±5°C, pass air into the reaction solution, and add calcium carbonate in batches to adjust pH to 7.0, and then pass air until the pH value of the reaction solution no longer drops.

[0039] Filter with a 0.45 μm filter, add 2.5 g of activated carbon, stir and decolorize at 70° C. for 1 hour, and filter with a 0.45 μm filter.

[0040] Measure the volume of the filtrate to be 490mL, add 735mL of isopropanol, cool to 20°C, keep warm and crystallize for 2 hours, filter, and dry the filter cake at 65°C to obtain 57.0g of calcium gluconate monohydrate, with a yield of 91.6%, purity 99.88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com