Preparation method of superconducting tape insulating coating

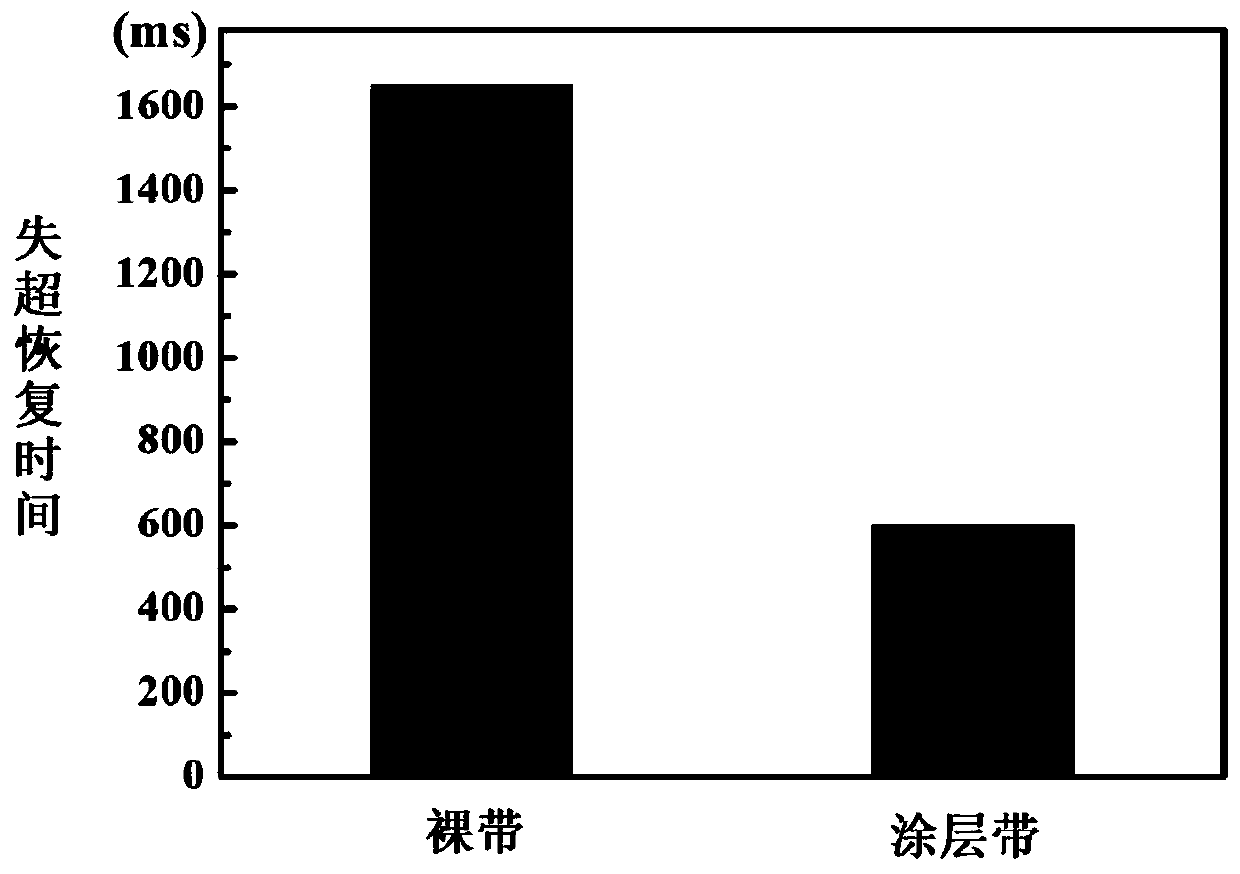

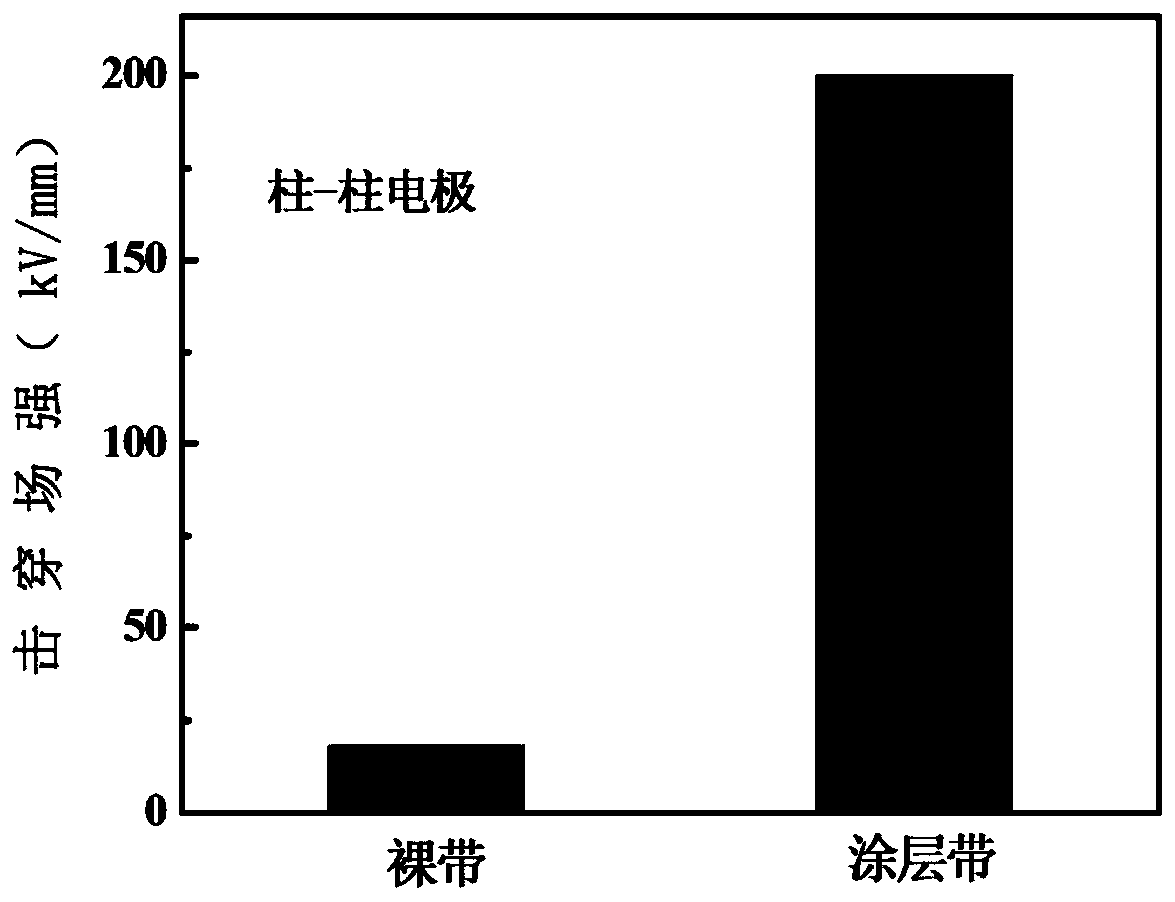

A technology of insulating coating and superconducting tape, which is applied to coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of main insulation breakdown, dissipation, boiling, etc., and achieve stable insulation strength and process Simple and easy to implement, the effect of accelerating quench recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing an insulating coating of a superconducting tape, wherein the insulating coating is boron nitride aerogel; the specific preparation method comprises:

[0030] (1) Preparation of boron nitride hydrosol

[0031] Weigh 2g of hexagonal boron nitride (h-BN) with a size of 200µm and add it to a mixed solution of water and isopropanol (100ml / 100ml), and ultrasonically disperse at room temperature for 24 hours to finally obtain 10mg / ml of boron nitride-water- Dispersion A in isopropanol. Meanwhile, 1 g of polyvinylpyrrolidone was dissolved in 200 ml of water to make an aqueous solution B. After mixing the boron nitride-water-isopropanol dispersion A and aqueous solution B, add 0.05g sodium dodecylbenzenesulfonate and stir for 30min at a speed of 10000rad / min to prepare a foamy boron nitride hydrosol ;

[0032] (2) Preparation of boron nitride hydrogel coating on the surface of superconducting strips

[0033] Apply the prepared boron nitride hydrosol on...

Embodiment 2

[0037] A method for preparing an insulating coating of a superconducting tape, wherein the insulating coating is boron nitride aerogel; the specific preparation method comprises:

[0038] (1) Preparation of boron nitride hydrosol

[0039] Weigh 1g of hexagonal boron nitride (h-BN) with a size of 50nm and 1g of hexagonal boron nitride (h-BN) with a size of 500µm, add it to a mixed solution of water and isopropanol (100ml / 100ml), and ultrasonically disperse at room temperature After 12 hours, a 10 mg / ml boron nitride-water-isopropanol dispersion A was finally obtained. Meanwhile, an aqueous solution B was prepared by dissolving 2 g of polyvinylpyrrolidone into 200 ml of water. After mixing the boron nitride-water-isopropanol dispersion A and aqueous solution B, add 0.2 g of sodium dodecylbenzenesulfonate and stir for 30 min at a speed of 15000 rad / min to prepare a foamy boron nitride hydrosol ;

[0040] (2) Preparation of boron nitride hydrogel coating on the surface of super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com