Laser cladding method for nickel base alloy laser cladding powder

A laser cladding, nickel-based alloy technology, applied in metal processing equipment, metal material coating process, coating and other directions, can solve the problem of difficult to obtain cladding layer and cladding effect, difficult to apply to industrial production, complex process control, etc. problem, to achieve the effect of effective matching, reducing thermal stress, simple and flexible operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A nickel-based alloy powder laser cladding process, comprising the following steps:

[0038] (1) Select nickel-based alloy laser cladding powder for laser cladding, put the powder into an inert gas protection drying box for drying;

[0039] (2) Grinding the surface of the parts to be clad, and cleaning with ethanol to remove surface impurities;

[0040] (3) Put the powder into the coaxial powder feeder of the cladding equipment, and spray it on the surface of the part to be clad through the powder feeder, and use a semiconductor laser to spray on the surface of the part to be clad according to certain laser processing parameters and scanning methods Perform laser cladding.

[0041] In step (1), the chemical composition of the nickel-based alloy laser cladding powder is Cr: 20.03%, C: 0.05%, Si: 0.035%, Mn: 0.063%, Mo: 3.05%, Al: 0.56%, Ti: 0.89% %, Ni: 52.64%, Fe: 22.6% and a small amount of unavoidable impurities.

[0042] The purity of the nickel base alloy laser c...

Embodiment 2

[0051] A nickel-based alloy powder laser cladding process, comprising the following steps:

[0052] (1) Select nickel-based alloy laser cladding powder for laser cladding, put the powder into an inert gas protection drying box for drying;

[0053] (2) Grinding the surface of the parts to be clad, and cleaning with ethanol to remove surface impurities;

[0054] (3) Put the powder into the coaxial powder feeder of the cladding equipment, and spray it on the surface of the part to be clad through the powder feeder, and use a semiconductor laser to spray on the surface of the part to be clad according to certain laser processing parameters and scanning methods Perform laser cladding.

[0055] In step (1), the chemical composition of the powder is Cr: 17-21%, C: ≤0.08%, Si: ≤0.35%, Mn: ≤0.35%, Mo: 2.8-3.3%, Al: 0.2-0.8%, Ti: 0.65-1.15%, Ni: 55-58%, and the balance is Fe and unavoidable impurities.

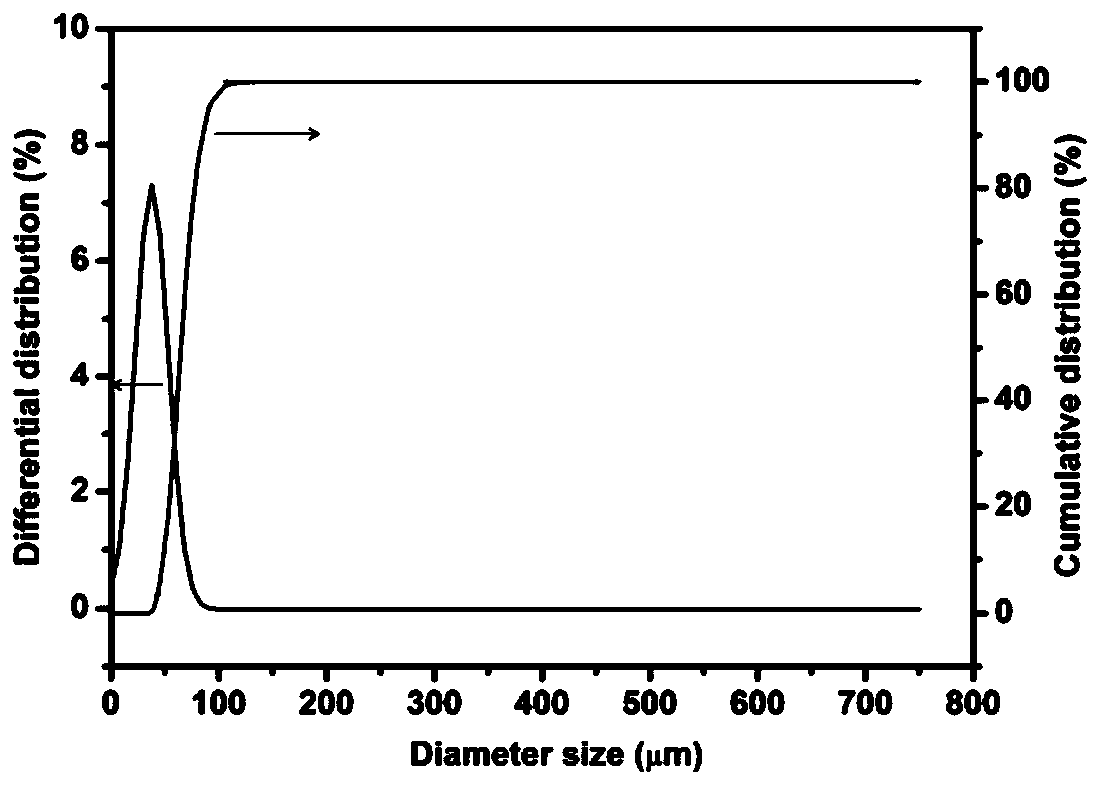

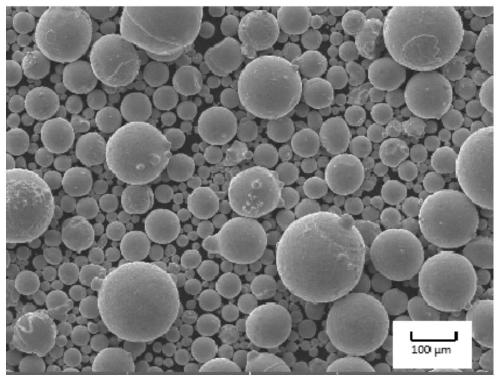

[0056] In step (1), the purity of the powder is greater than 99%, and the partic...

Embodiment 3

[0061] A laser cladding method for nickel-based alloy laser cladding powder, comprising the following steps:

[0062] 1) Dry the laser cladding powder under the protection of nitrogen to remove trace moisture, improve the fluidity of the powder, and effectively avoid the increase of oxygen content in the powder; the drying temperature is 90°C, and the drying time is 6 hours; end After that, continue to pass cold nitrogen gas to cool down, and take it out after the temperature is lower than 35°C.

[0063] 2) Grinding the surface of the parts to be clad and cleaning with acetone to remove surface stains and impurities;

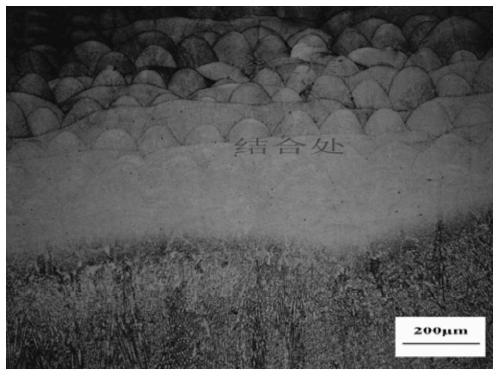

[0064] 3) Coat the laser cladding powder on the surface of the part to be clad, and use a semiconductor laser to perform laser cladding under the protection of nitrogen according to the set laser cladding parameters and scanning mode, and the nitrogen flow rate is 8L / min.

[0065] In step 1), the nickel-based alloy laser cladding powder includes the following c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com