Enhanced AlN/AlGaN/GaN HEMT device and preparation method thereof

An enhanced device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficulty in realizing enhanced devices, device failure, device damage, etc., and achieve threshold voltage and large saturation current enhancement mode device, high threshold voltage and high saturation current enhancement mode device, avoiding the effect of low saturation current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

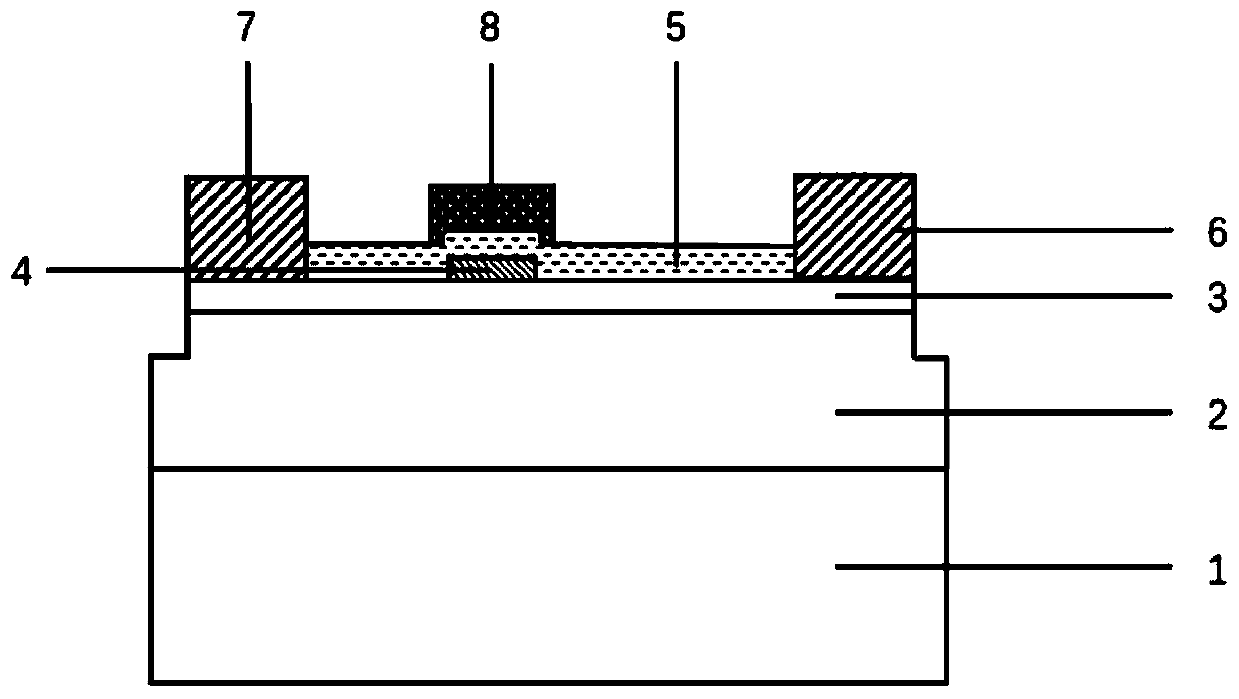

[0053] An enhanced AlN / AlGaN / GaN HEMT device in this embodiment, its structural schematic diagram is as follows figure 1 shown. Including: substrate 1, GaN channel layer 2, AlGaN ultra-thin barrier layer 3, amorphous SiO 2 Layer 4, single crystal AlN layer 5, drain metal electrode 6, source metal electrode 7 and gate metal electrode 8, wherein:

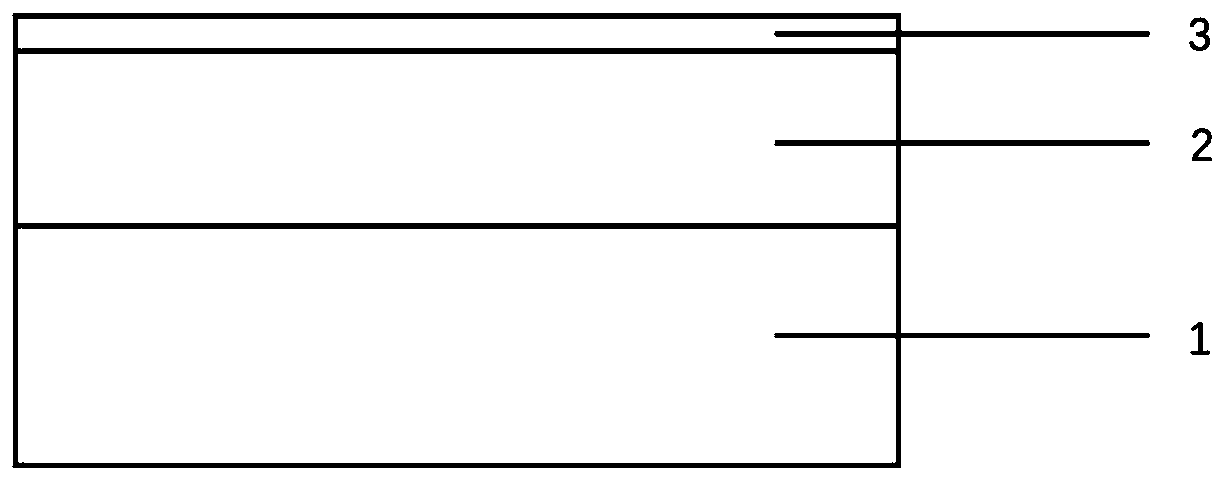

[0054] The substrate 1, GaN channel layer 2 and AlGaN ultra-thin barrier layer 3 are stacked sequentially from bottom to top;

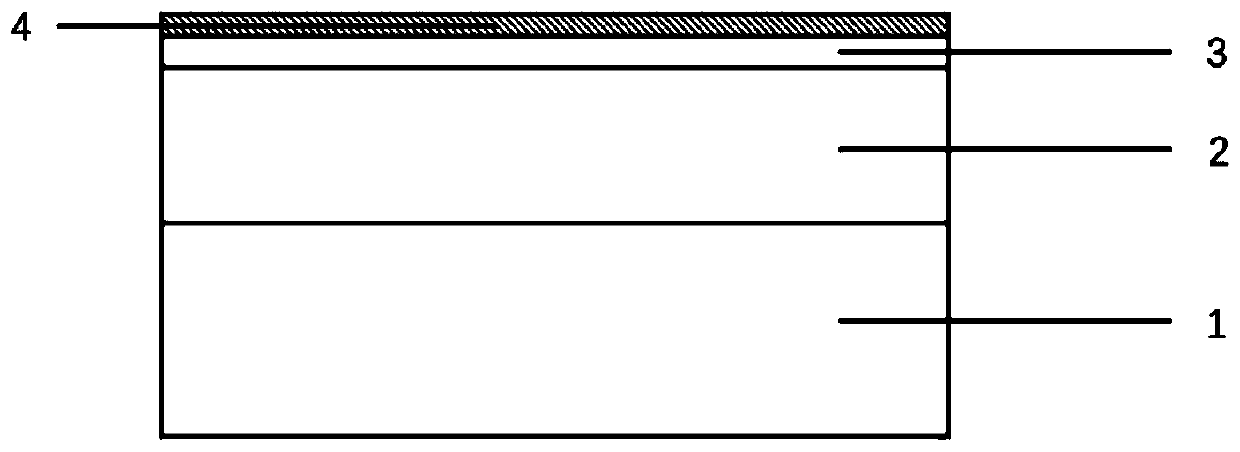

[0055] The amorphous SiO 2 Layer 4 covers a part of the upper surface of the AlGaN ultra-thin barrier layer 3;

[0056] The drain metal electrode 6 and the source metal electrode 7 are located on the upper surface of the AlGaN ultra-thin barrier layer 3 and are not covered with amorphous SiO 2 On both sides covered by the layer 4, ohmic contact is formed between the drain metal electrode 6 and the source metal electrode 7 and the AlGaN ultra-thin barrier layer 3;

[0057] The single crystal AlN layer 5 c...

Embodiment 2

[0070] An enhanced AlN / AlGaN / GaN HEMT device in this embodiment, its structural schematic diagram is as follows figure 1 As shown, it includes: substrate 1, GaN channel layer 2, AlGaN ultra-thin barrier layer 3, amorphous SiO2 layer 4, single crystal AlN layer 5, drain metal electrode 6, source metal electrode 7 and gate metal electrode 8, in:

[0071] The substrate 1, GaN channel layer 2 and AlGaN ultra-thin barrier layer 3 are stacked sequentially from bottom to top;

[0072] The amorphous SiO 2 Layer 4 covers a part of the upper surface of the AlGaN ultra-thin barrier layer 3;

[0073] The drain metal electrode 6 and the source metal electrode 7 are located on the upper surface of the AlGaN ultra-thin barrier layer 3 and are not covered with amorphous SiO 2 On both sides covered by the layer 4, ohmic contact is formed between the drain metal electrode 6 and the source metal electrode 7 and the AlGaN ultra-thin barrier layer 3;

[0074] The single crystal AlN layer 5 cov...

Embodiment 3

[0087] An enhanced AlN / AlGaN / GaN HEMT device in this embodiment, its structural schematic diagram is as follows figure 1 As shown, it includes: substrate 1, GaN channel layer 2, AlGaN ultra-thin barrier layer 3, amorphous SiO2 layer 4, single crystal AlN layer 5, drain metal electrode 6, source metal electrode 7 and gate metal electrode 8, in:

[0088] The substrate 1, GaN channel layer 2 and AlGaN ultra-thin barrier layer 3 are stacked sequentially from bottom to top;

[0089] The amorphous SiO2 layer 4 covers a part of the upper surface of the AlGaN ultra-thin barrier layer 3;

[0090] The drain metal electrode 6 and the source metal electrode 7 are respectively located on the two sides of the upper surface of the AlGaN ultra-thin barrier layer 3 that are not covered by the amorphous SiO2 layer 4, and the drain metal electrode 6 and the source metal electrode 7 are connected to the AlGaN ultra-thin barrier layer. Ohmic contact is formed between layers 3;

[0091] The sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com