Oil-in-water type emulsion cosmetic

An emulsified cosmetic, oil-in-water type technology, applied in the direction of cosmetics, cosmetic preparations, dressing preparations, etc., can solve the problems of insufficient satisfaction, etc., to inhibit melanin production, promote collagen production, and inhibit peroxidation The effect of lipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1( Embodiment 1-1、1-2

[0095] Example 1 (Example 1-1, 1-2): Evaluation of pH

[0096] Measure the first phase and the second phase shown in Table 1 respectively, heat to ··°C, and dissolve uniformly. Next, the first phase was gradually added to the second phase, stirred and emulsified with a homomixer, cooled to 40° C., and the third phase was added to obtain a cosmetic. The numerical value of each component in a table shows mass %.

[0097] [Table 1]

[0098]

[0099] As a result, since pH was adjusted using the polar oil of (B) component, the chelating agent of (C) component, and the antioxidant of (D) component, the hydrolysis of (A) component was suppressed. In the case of pH 6 or less, hydrolysis of (A) component was further suppressed in Example 1-1 of pH 5.5 or less which was lower in pH.

Embodiment 2( Embodiment 2-1、2-2

[0100] Example 2 (Example 2-1, 2-2): Buffer evaluation

[0101] Cosmetics were prepared in the same manner as in Example 1 using each component shown in Table 2.

[0102] [Table 2]

[0103]

[0104] As a result, since the polar oil of (B) component, the chelating agent of (C) component, the antioxidant of (D) component, and the higher alcohol (3.50% by mass) of (G) component were used, and the pH was adjusted, the (A) Hydrolysis of component. In the case of pH 6 or less, hydrolysis of (A) component was further suppressed in Example 2-2 of pH 5.5 or less which was lower in pH. In addition, in Example 2-2, the use of succinic acid having a chelating effect as a pH adjuster is considered to have an influence on suppression of hydrolysis of the component (A).

Embodiment 3( Embodiment 3-1、3-2、3-3

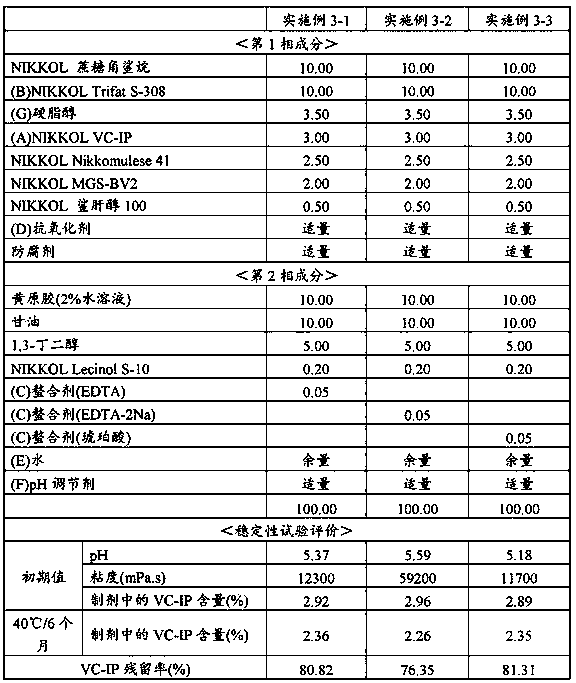

[0105] Embodiment 3 (embodiment 3-1, 3-2, 3-3): Chelating agent evaluation

[0106] Cosmetics were prepared in the same manner as in Example 1 using each component shown in Table 3.

[0107] [table 3]

[0108]

[0109] As a result, since the polar oil of (B) component, the chelating agent of (C) component, the antioxidant of (D) component, a small amount of (G) component (3.50% by mass) were used, and the pH was adjusted, the ( A) Hydrolysis of ingredients. The effect of suppressing the hydrolysis of component (A) by the chelating agent of component (C) is in the order of succinic acid (Example 3-3), EDTA (Example 3-1), and EDTA-2Na (Example 3-2). The presence of Na ions is the cause of the decrease in the inhibitory effect of Example 3-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com