Rolled copper foil for lithium ion battery current collector and lithium ion battery

A technology for lithium-ion batteries and rolled copper foil, which is applied to battery electrodes, electrode carriers/current collectors, secondary batteries, etc., and can solve problems such as peeling and adhesion of active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

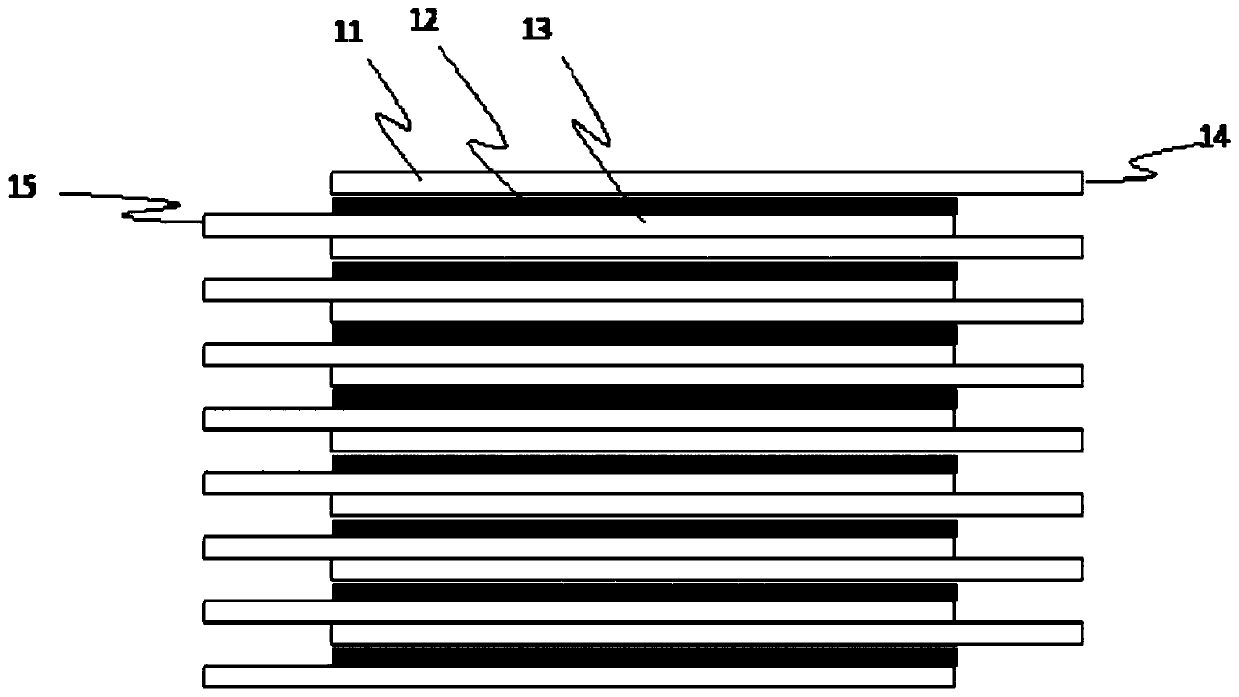

Image

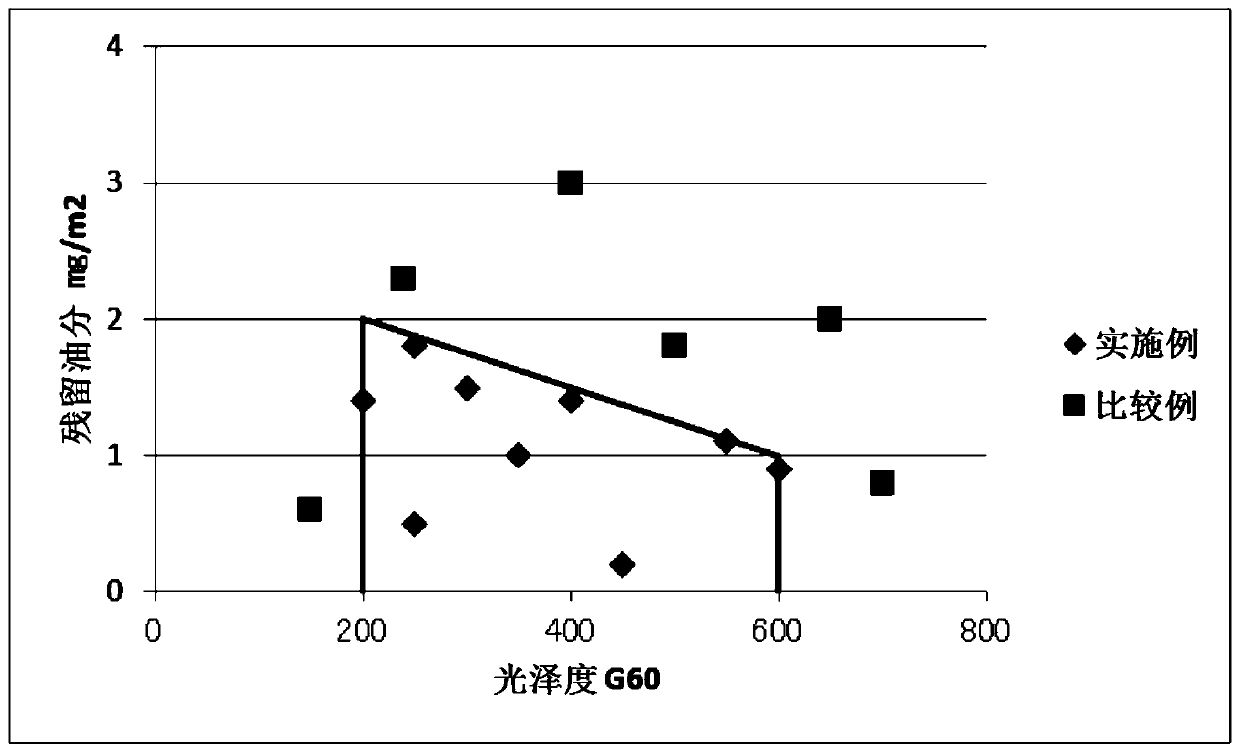

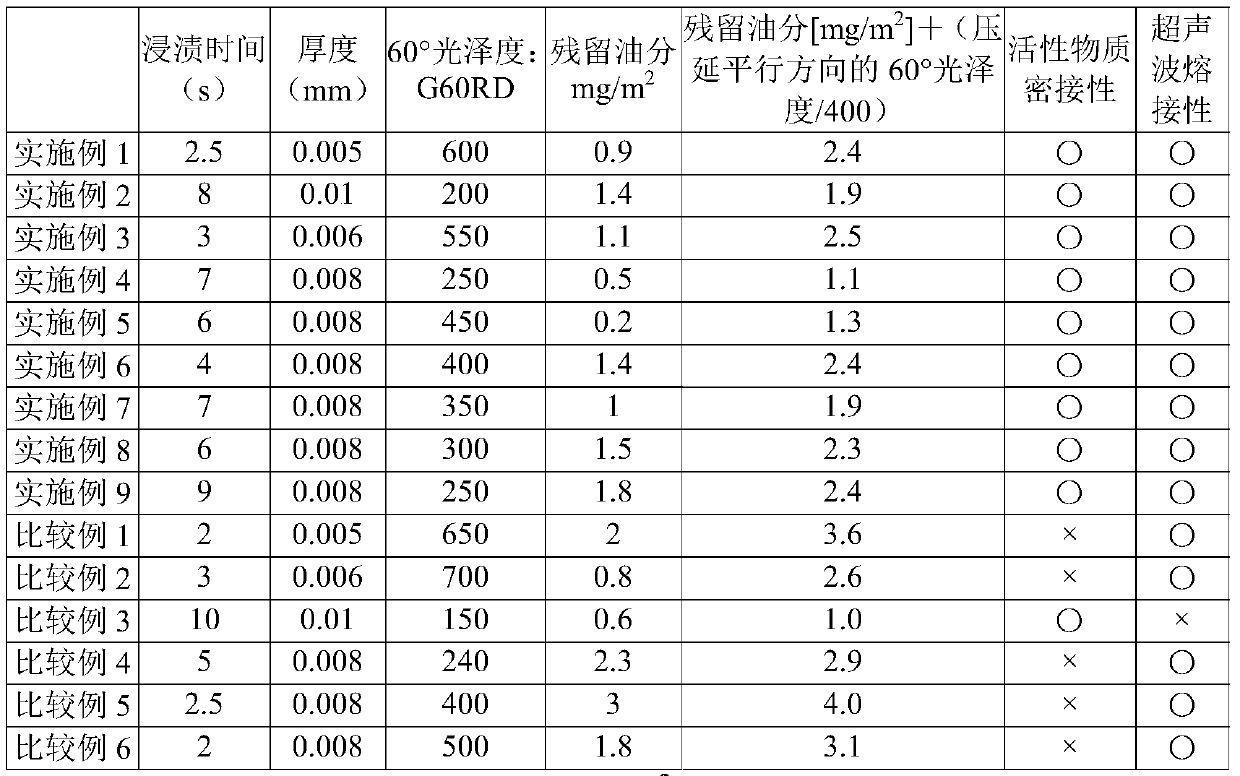

Examples

Embodiment 1~9

[0035] (Examples 1-9, Comparative Examples 1-6)

[0036] [Manufacture of rolled copper foil]

[0037] A refined copper ingot with a width of 600 mm was manufactured and rolled by hot rolling.

[0038] Next, repeat annealing and cold rolling, and finally cold rolling, and set the diameter of the work roll to 60mm, set the surface roughness Ra of the work roll to 0.03 μm, and finally process it into a table with a rolling speed of 400m / min in the final pass. Thickness described in 1. The viscosity of the calendering oil was 4.0 cSt (25°C). Ra of the obtained rolled copper foil was 0.04 μm. In this state, oil components such as rolling oil used for final cold rolling adhere to the copper foil. The copper foil was washed with a solution containing a petroleum-based solvent and an anionic surfactant to remove copper fine powder and rolling oil adhering to the surface of the copper foil, followed by air drying.

[0039] The rolling oil on the surface of the copper foil was remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com