Novel water-based fire extinguishing agent

A fire extinguishing agent and water system technology, applied in fire prevention equipment, etc., can solve problems such as high freezing point, low fire extinguishing efficiency, and limited use range of water system fire extinguishing agents, and achieve the effects of reducing corrosion, high fire extinguishing efficiency, and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

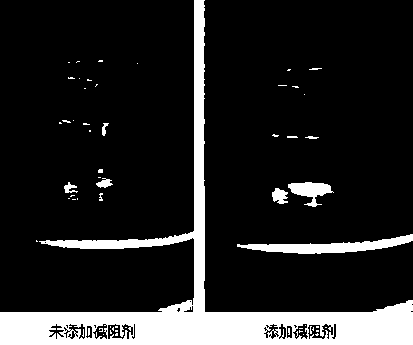

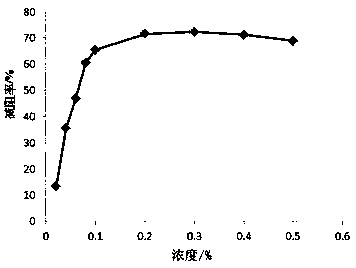

Image

Examples

Embodiment 1

[0037]The compounding of novel water system fire extinguishing agent: with 20g water-in-water type polyacrylamide emulsion (its solid content is 20%); 50g carbonamide; 100g of ammonium dihydrogen phosphate and diammonium hydrogen phosphate mixing (its mass ratio is 2:1); 1g of sodium gluconate; 829g of water-based medium (being a self-made water system fire extinguishing agent, the specific components are as follows: sodium lauryl sulfate is 20g / L, betaine DSB is 20g / L, AF4018-Z is 4ml / L, polyvinyl alcohol 0.25g / L, ammonium oxalate 20g / L, melamine 20g / L, foam glass 0.10g / L, ammonium oxide 0.12g / L, magnesium hydroxide 0.1g / L, tetrahydrofuran 0.15ml / L, the balance being water) and mix well, and stir evenly.

[0038] Among them, the preparation of water-in-water polyacrylamide emulsion: 350g of ammonium sulfate, 100ml of dodecyl mercaptan and 900ml of deionized water were successively added into a three-necked flask as a reaction medium, 100g of acrylamide monomer, 80g of 2 -Acr...

Embodiment 2~6

[0040] The following table is the concrete charging amount of embodiment 1~6:

[0041] Feeding amount / g Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Drag reducer 20 2.5 1 2 4 25 coolant 50 5 5 1 3 50 antifreeze 100 50 50 100 150 150 anti-corrosion agent 1 0.5 1 3 3 5 aqueous medium 829 942 943.5 894 840 770

[0042] The following table is the used material of embodiment 1~6:

[0043]

[0044] Among them, the self-made fire extinguishing agent is a class A water-based fire extinguishing agent made by Nanjing University of Science and Technology. Polyvinyl alcohol is 0.25g / L, ammonium oxalate is 20g / L, melamine is 20g / L, foam glass is 0.10g / L, ammonium oxide is 0.12g / L, magnesium hydroxide is 0.1g / L, tetrahydrofuran is 0.15ml / L, the balance is water; the water-in-water polyacrylamide emulsion is prepared in Example 1, and its solid content is 20%, and the rest of the medicines ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap