Preparation method and applications of B-SBA-16 loaded silicotungstic acid type ionic liquid composite catalyst

A B-SBA-16, 1. B-SBA-16 technology, applied in the field of immobilized ionic liquid composite catalysts, can solve the problems of not widely used and difficult synthesis process, so as to improve the catalytic effect and strengthen the acidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

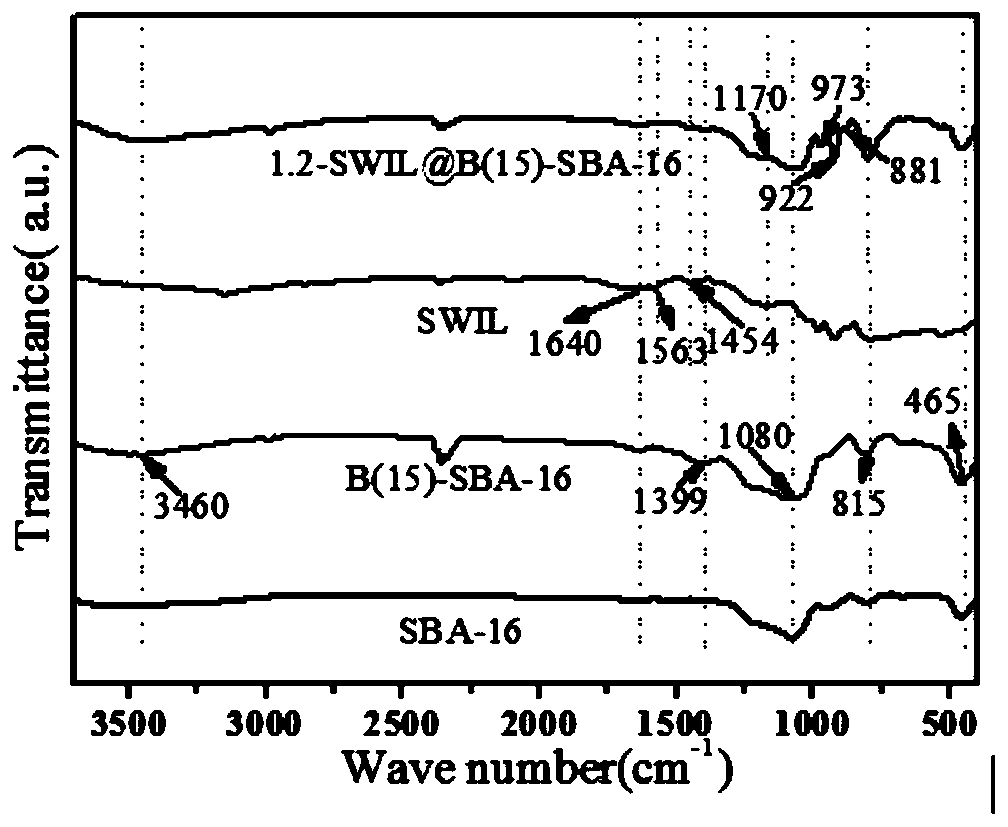

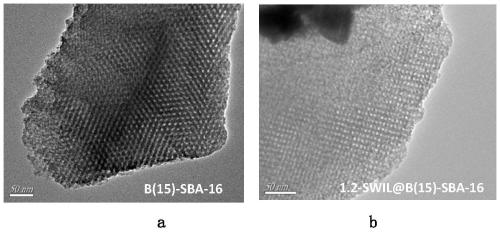

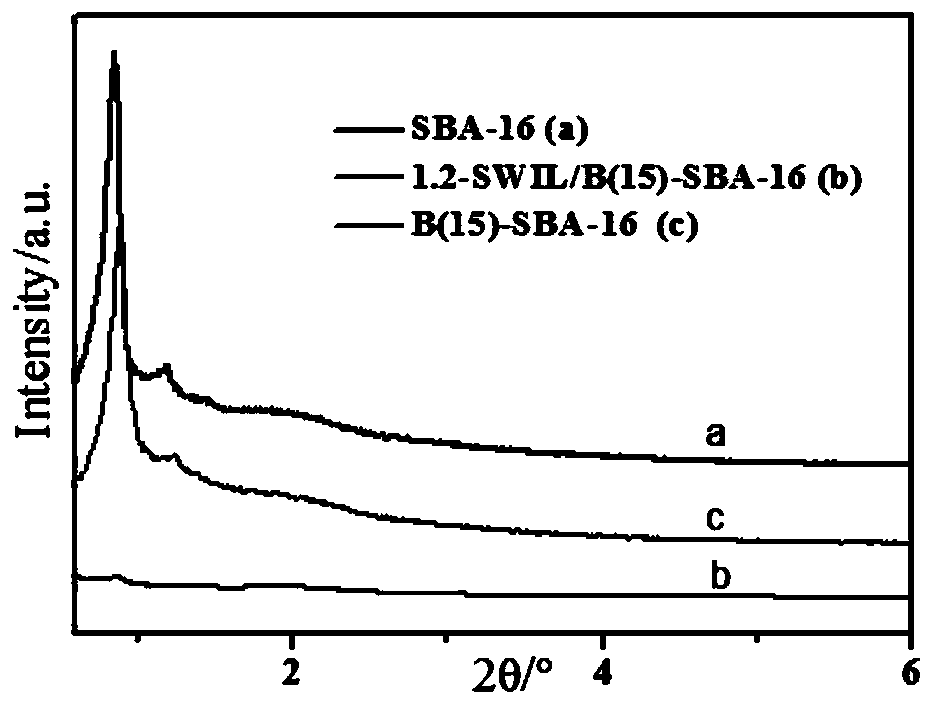

[0035] First, prepare B-SBA-16, and then prepare the silicotungstic acid ionic liquid. After the ionic liquid is successfully prepared, it is introduced into the pores of the molecular sieve to obtain the immobilized ionic liquid. The specific method is as follows:

[0036] Step 1. Synthesis of B-SBA-16

[0037] Dissolve 2g of F127 in 90ml of 1.62mol / L hydrochloric acid in a beaker, stir magnetically until the solution is clear and transparent, transfer the solution to a 250ml three-necked flask, drop 8g of TEOS into the flask drop by drop, and then continue to 34 Stir vigorously in a water bath at ℃ for 20h; after the reaction, filter and wash with suction, transfer the filter cake to a polytetrafluoroethylene reactor, add a certain amount of deionized water, stir evenly, aging in a hydrothermal environment at 100℃ for 24h, the aging is over Then continue to filter and wash for 2-3 times, then dry at 100°C for 12h; calcined at 550°C to remove the template, heating rate 1°C / min, ho...

Embodiment 2

[0050] The solid-supported ionic liquids with the silicon to boron ratios of 30 and 10 were prepared according to the steps of Example 1, and the obtained composite catalyst was used to catalyze the reaction of cyclohexanone and ethylene glycol ketal.

[0051] According to the molar ratio of ketone to alcohol is 1:1.8, add 1.96g cyclohexanone to the flask, the reaction temperature is 85℃, the amount of catalyst is 0.25g, and the reaction time is 3h. The effect of different B doping amount on the catalytic performance of the composite catalyst is investigated. The experiment shows When the ratio of silicon to boron is 30, the conversion rate of cyclohexanone is 93.01% and the yield of ketal is 78.39%. When the ratio of silicon to boron is 10, the conversion rate of cyclohexanone is 90.49% and the yield of ketal is 84.24%. This result shows that when the ratio of silicon to boron is 15, the obtained composite catalyst has the best catalytic effect.

Embodiment 3

[0053] According to the steps of Example 1, by changing the loading amount of the ionic liquid, a solid-supported ionic liquid with a loading amount of 0.8 g and 1.5 g was prepared, and the effect on the catalytic reaction of cyclohexanone and ethylene glycol ketal was investigated.

[0054] According to the ketone alcohol molar ratio of 1:1.8, 1.96g cyclohexanone was added to the flask, the reaction temperature was 85°C, the amount of catalyst was 0.25g, and the reaction time was 3h. The results showed that when the loading amount of ionic liquid was 0.8g, the conversion rate of cyclohexanone was 90.94% and the yield of ketal was 66.41%; and when the loading amount of ionic liquid was 1.5g, the conversion rate of cyclohexanone was 91.09. %, the ketal yield is 69.05%. Therefore, the optimal load of ionic liquid per gram of B-SBA-16 is 1.2g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com