Preparing method of denitration catalyst regeneration intensity repair fluid and repair fluid and regeneration denitration catalyst thereof

A technology for denitration catalyst and repair solution, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of improving the property, repairing the mechanical strength, and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

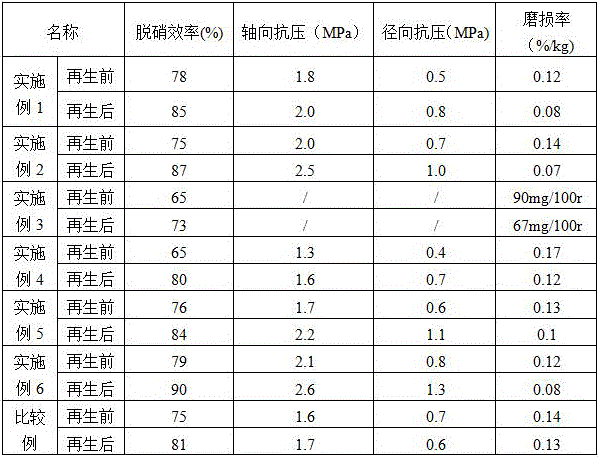

Examples

Embodiment 1

[0031] The preparation process of strength restoration fluid is as follows:

[0032] (1) At room temperature, take 8 parts by weight of titanium dioxide containing 5% tungsten, 3 parts of silica sol, 0.5 parts of activated alumina and 85 parts of deionized water, and add them to the mixer, stir until they are evenly mixed to obtain a suspension ;

[0033] (2) Add 0.05 parts by weight of methyl cellulose (binder) to the suspension obtained in step (1), stir until the methyl cellulose is completely dissolved, then add 0.5 mol / L nitric acid to adjust the pH to 3, forming Stabilize the solution; then add 0.1 parts by weight of ammonium metavanadate and ball mill for 1 hour to obtain the strength restoration solution with a particle size of D 90 3.5 μm.

[0034] The application of strength repair fluid in the regeneration of denitrification catalyst, the operation steps are as follows:

[0035] (i) The honeycomb denitrification catalyst deactivated after use is 150 mm × 150 mm ...

Embodiment 2

[0038] The preparation process of strength restoration fluid is as follows:

[0039] (1) At room temperature, take 10 parts of titanium dioxide containing 3% tungsten, 2 parts of silica sol, 1 part of pseudoboehmite and 85 parts of deionized water in parts by weight, and add them to the mixer, and stir until they are evenly mixed and suspended. turbid liquid;

[0040] (2) Add 0.1 parts by weight of hydroxymethyl cellulose (binder) to the suspension obtained in step (1), stir until the methyl cellulose is completely dissolved, then add 0.8 mol / L sulfuric acid to adjust the pH to 1, Form a stable solution; then add 1 part by weight of vanadyl sulfate, and ball mill for 3 hours to obtain a strength restoration solution with a particle size of D 90 2.0 μm.

[0041] The application of strength repair fluid in the regeneration of denitrification catalyst, the operation steps are as follows:

[0042] (i) The deactivated honeycomb denitrification catalyst after use is 150mm×150mm×...

Embodiment 3

[0045] The preparation process of strength restoration fluid is as follows:

[0046] (1) At room temperature, take 8 parts by weight of molybdenum-containing 5% titanium dioxide, 3 parts of silica sol, 0.8 parts of pseudoboehmite and 85 parts of deionized water, and add them to the mixer, and stir until they are evenly mixed and suspended. turbid liquid;

[0047] (2) Add 0.05 parts by weight of polyethylene oxide (binder) to the suspension obtained in step (1), stir until the methyl cellulose is completely dissolved, then add 0.6 mol / L hydrochloric acid to adjust the pH to 3 to form a stable solution; then add 0.1 parts by weight of ammonium metavanadate and ball mill for 3 hours to obtain the strength restoration solution with a particle size of D 90 4.0 μm.

[0048] The application of strength repair fluid in the regeneration of denitrification catalyst, the operation steps are as follows:

[0049] (i) The plate-type denitrification catalyst 456mm×456mm×500mm that has be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com