High-efficiency sludge conditioning and dehydrating method

A sludge conditioning and sludge technology, which is applied in biological sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of poor sludge dewatering performance, high cost, Poor stability and other problems, to achieve the effect of improving dehydration effect, stable material properties, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

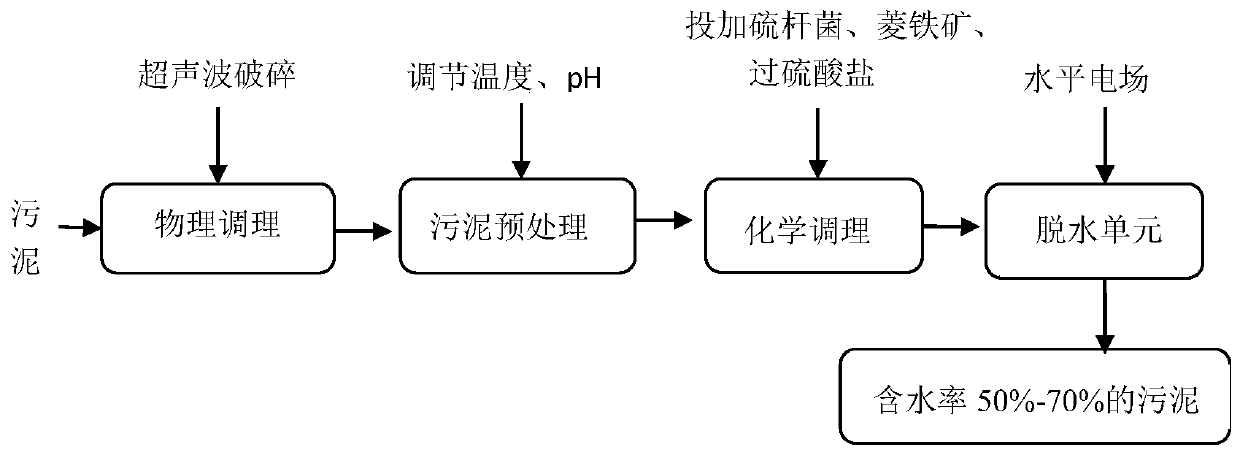

Image

Examples

Embodiment 1

[0031] The sludge to be dewatered is collected from a sewage treatment plant in a certain city, which uses the traditional activated sludge process to treat municipal sewage. The activated sludge collection point is located somewhere on the return path from the secondary sedimentation tank to the aeration tank. The sludge concentration (MLSS) reached 20.0g / L, the water content was 97.328%, and the temperature and pH were 25°C and 6.5, respectively.

[0032] 1) Take 300mL of activated sludge and place it in a beaker;

[0033] 2) Treat the sludge with ultrasonic waves with a frequency of 1k-5kHz for 5 minutes;

[0034] 3) Add 0.02g / g TSS Thiobacillus and 0.05g / gTSS siderite and 0.10g / gTSS potassium hydrogen persulfate to the sludge, turn on the mechanical stirrer, stir the sludge, the stirring intensity is 100r / min, then keep stirring for 30min;

[0035] 4) Gravity sedimentation is carried out to the conditioned sludge, and then the filtrate is discharged;

[0036] 5) Turn o...

Embodiment 2

[0039] The sludge to be dewatered is collected from a sewage treatment plant in a certain city, which uses the traditional activated sludge process to treat municipal sewage. The activated sludge collection point is located somewhere on the return path from the secondary sedimentation tank to the aeration tank. The sludge concentration (MLSS) reached 20.0g / L, the water content was 97.330%, and the temperature and pH were 25°C and 6.5, respectively.

[0040] 1) Take 300mL of activated sludge and place it in a beaker;

[0041] 2) Treat the sludge with ultrasonic waves with a frequency of 8k-10kHz for 25min;

[0042] 3) Add 0.04g / g TSS Thiobacillus and 0.10g / gTSS siderite and 0.20g / gTSS potassium hydrogen persulfate to the sludge, turn on the mechanical stirrer, stir the sludge, the stirring intensity is 100r / min, then keep stirring for 10min;

[0043] 4) Gravity sedimentation is carried out to the conditioned sludge, and then the filtrate is discharged;

[0044] 5) Turn on t...

Embodiment 3

[0047] The sludge to be dewatered is collected from a sewage treatment plant in a certain city, which uses the traditional activated sludge process to treat municipal sewage. The activated sludge collection point is located somewhere on the return path from the secondary sedimentation tank to the aeration tank. The sludge concentration (MLSS) reached 20.0g / L, the water content was 97.322%, and the temperature and pH were 25°C and 6.5, respectively.

[0048] 1) Take 300mL of activated sludge and place it in a beaker;

[0049] 2) Treat the sludge with ultrasonic waves with a frequency of 1k-5kHz for 5 minutes;

[0050] 3) Add 0.02g / g TSS Thiobacillus, 0.10g / gTSS siderite and 0.20g / gTSS potassium hydrogen persulfate to the sludge, turn on the mechanical stirrer, stir the sludge, the stirring intensity is 100r / min, then keep stirring for 30min;

[0051] 4) Gravity sedimentation is carried out to the conditioned sludge, and then the filtrate is discharged;

[0052] 5) Turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com