Method for extracting carnosic acid from Rosmarinus officinalis

A carnosic acid and rosemary technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem that the extraction process of carnosic acid is easily damaged, the product yield and quality are unstable, and the market adaptability is poor. and other problems, to achieve the effect of guaranteed purity, stable content and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

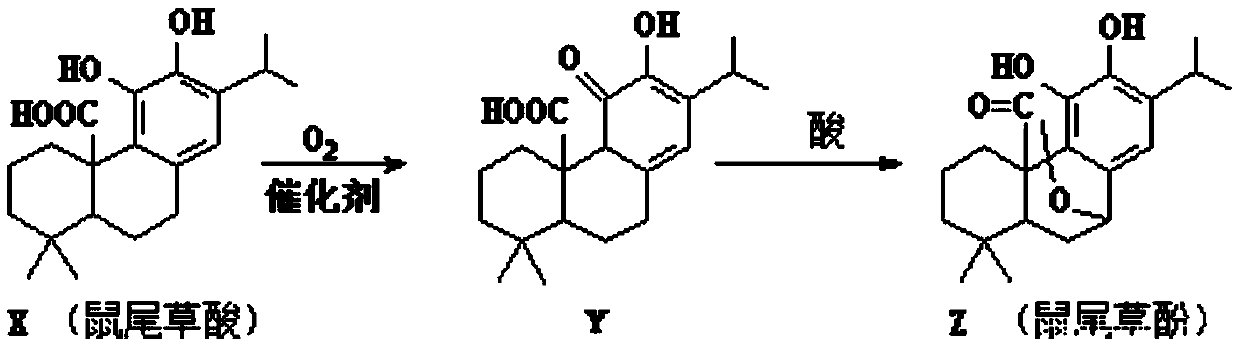

Image

Examples

Embodiment 1

[0028] In the present embodiment, the method for extracting carnosic acid from rosemary comprises the steps:

[0029] 1) Take 1 kg of rosemary dry leaves (wherein the content of carnosic acid is 2.41%) and pulverize into rosemary leaf powder;

[0030] 2) Add 6 L of ethanol with a concentration of 85% to the rosemary leaf powder and extract in a slightly boiling state for 2 hours, filter while hot after extraction to obtain the first extract and the first filter residue, and continue to add volume to the first filter residue 85% ethanol that is 6 times the mass of the first filter residue is used for secondary extraction, and the second extraction is extracted in a slightly boiling state for 2 hours. After extraction, the second extract and the second filter residue are obtained by filtering while hot. The conditions of extraction obtained the third extract and the third filter residue, combined the first extract, the second extract and the third extract, concentrated to drynes...

Embodiment 2

[0035] Get rosemary dry leaves 10kg (wherein carnosic acid content 2.41%) is ground into rosemary leaf powder and carries out pilot test after, test condition is consistent with embodiment 1, finally obtains the first product, and the first product is all reprocessed into a second product.

Embodiment 3

[0037] Get rosemary dry leaf 100kg (wherein carnosic acid content 2.41%) is ground into rosemary leaf powder and carry out pilot test after, test condition is consistent with embodiment 1, finally obtains the first product, and the first product is all reprocessed into a second product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com