Production method of winter jujube beer

A production method and technology for winter jujube, which are applied in beer fermentation methods, beer brewing, microorganism-based methods, etc., can solve the problems of destroying the taste of beer and inconspicuous fruit aroma of winter jujube, and achieve the effect of improving the aroma and nutrition of winter jujube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: fresh winter jujube juice pretreatment

[0026] After the fresh winter jujube is washed, it is beaten by a beater, and separated by a horizontal screw centrifuge to obtain the winter jujube dregs and fresh winter jujube juice, which are set aside.

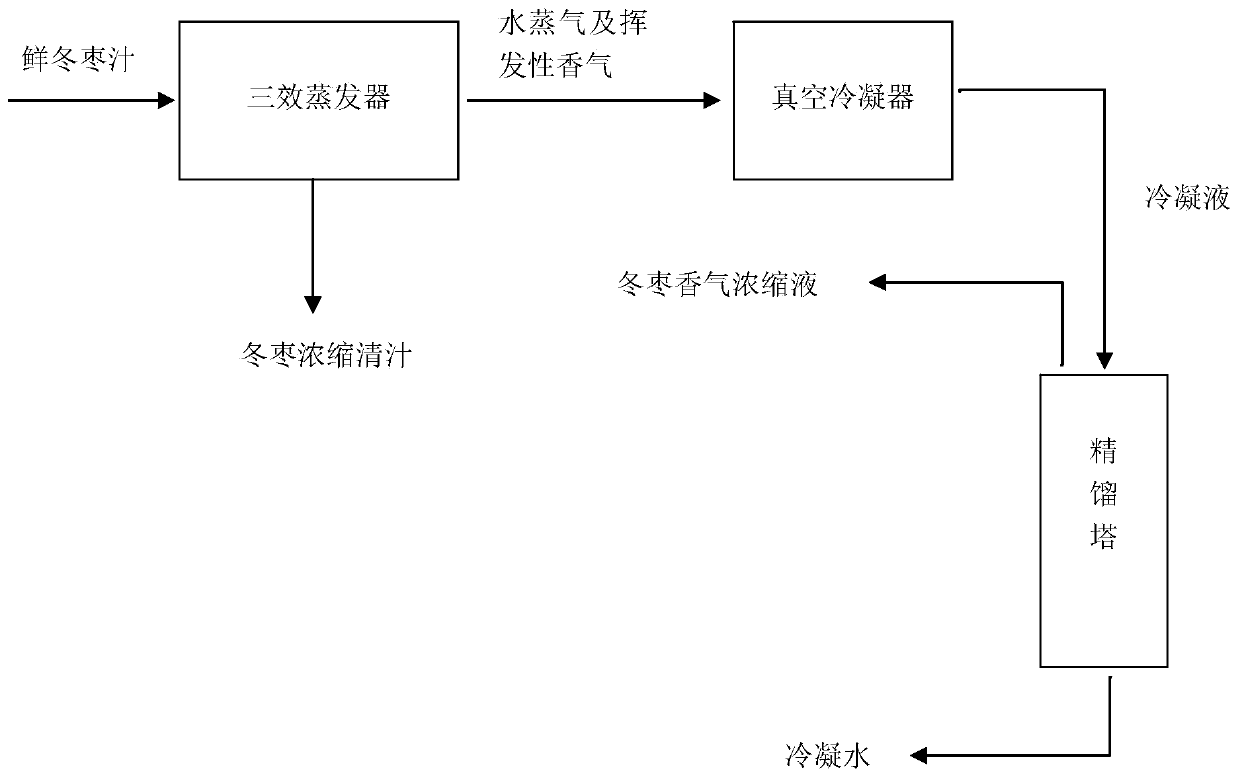

[0027] Such as figure 1 As shown, the fresh winter jujube juice enters the three-effect evaporator, wherein the temperature of the first evaporator is 90-95°C, the temperature of the second evaporator is 80-95°C, and the temperature of the third evaporator is 60-70°C; the degree of vacuum is: 10-50pa. In the three-effect evaporator, the fresh winter jujube juice itself begins to evaporate, the liquid part is vaporized, and the vapor phase and liquid phase are separated in the separator. The components of the vapor phase include water vapor and volatile aroma components that are condensed into a condensate through a vacuum condenser, while the less volatile components in the evaporator are concentrated to beco...

Embodiment 2

[0031] 1. Crushing: Mix barley malt and wheat malt in a mass ratio of 3:2, then pulverize and pass through a 40-mesh sieve;

[0032] 2. Cooking: mix winter jujube dregs (the ratio of winter jujube dregs to the total amount of barley malt and wheat germ is 1:5-1:10, 1:7.5 is selected in this embodiment) and crushed barley malt and wheat germ, and add 3 Double the quality of pure water, soak at 60°C for more than 30 minutes, and then cook for 30 minutes;

[0033] 3. Gelatinization: Add 2% of the total mass of α-amylase (enzyme activity ≥ 20000U / g) to the cooked jujube dregs, barley malt and wheat germ mixture, gelatinize at 70°C for 30 minutes, and stir while gelatinizing ;

[0034] 4. Saccharification: adjust the pH to 4.5 after gelatinization (the jujube dregs contain some organic acids, and the pH after mixing the jujube dregs and malt is basically 4.5), add 1.5% of its mass glucoamylase (enzyme activity ≥ 20000U / g) , saccharification at 60°C for 4-5 hours, after the saccha...

Embodiment 3

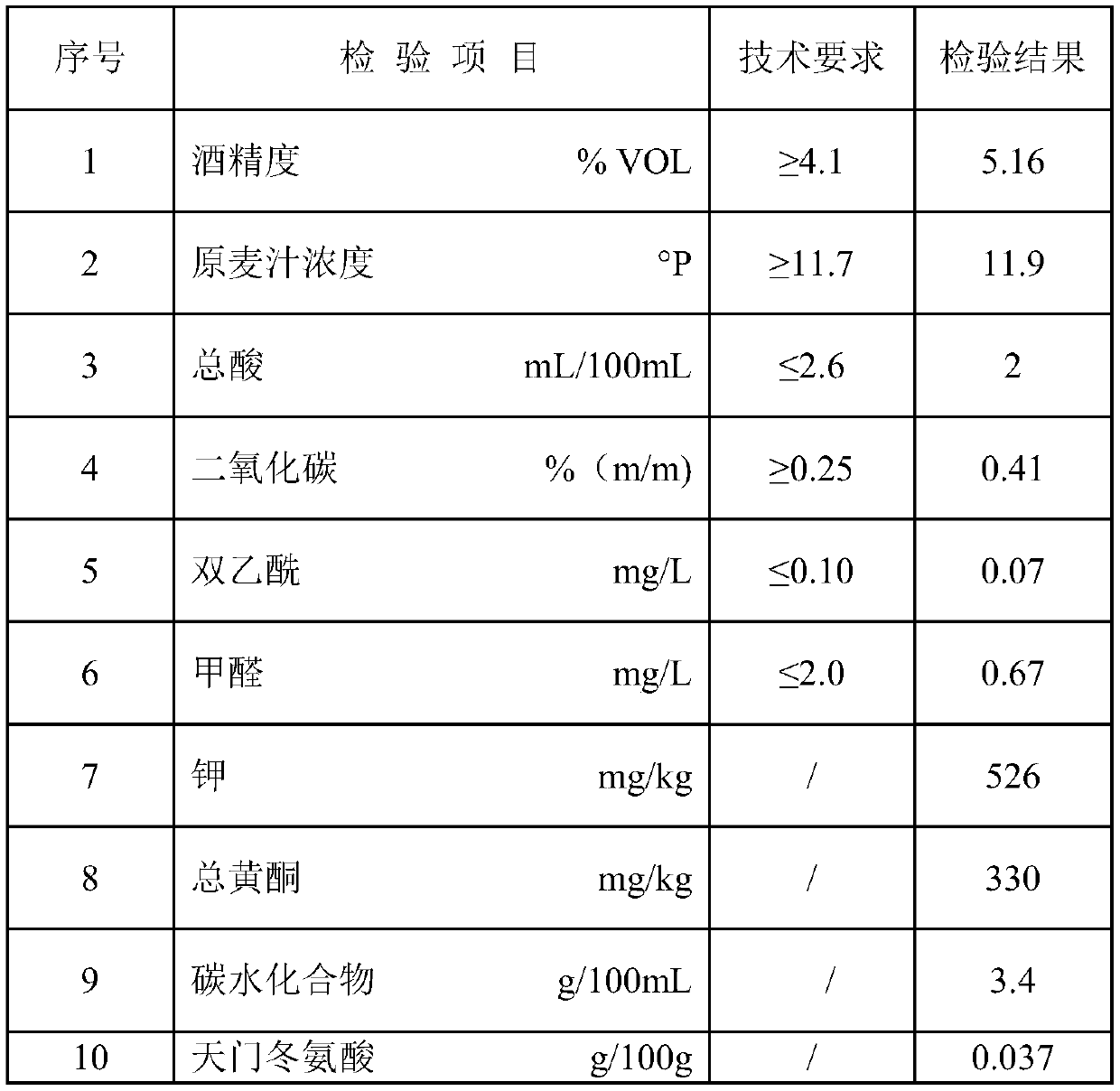

[0046] On the basis of the above-mentioned Dongzao beer, add 0.3% Dongzao aroma concentrate (water content 26.1%), adjust the flavor of Dongzao beer, make the clear fragrance of Dongzao beer richer and taste more refreshing. The main components of the aroma of Dongzao are capric acid, ethyl laurate, ethyl acetate, linalyl acetate, linalool oxide, and phyllyl caproate. After testing, the detection methods and results of the above aroma components in Dongzao beer are as follows Table 2 shows.

[0047] The detection method of the above aroma components:

[0048] Instruments and equipment:

[0049] Chromatograph: According to the regulations in Chapter 5 of GB / T11538-2006.

[0050] Column: capillary column.

[0051] Detector: hydrogen flame ionization detector.

[0052] Determination method area normalization method:

[0053] Determine the content according to 10.4 in GB / T11538-2006.

[0054] Table 2 The test report of the main aroma components of the product

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com