Light-emitting diode element, and method for manufacturing light-emitting diode element

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of high price, inability to realize the physical potential of nitride semiconductors, large crystal orientation deviation of dislocation density substrates, etc., and reduce lateral resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

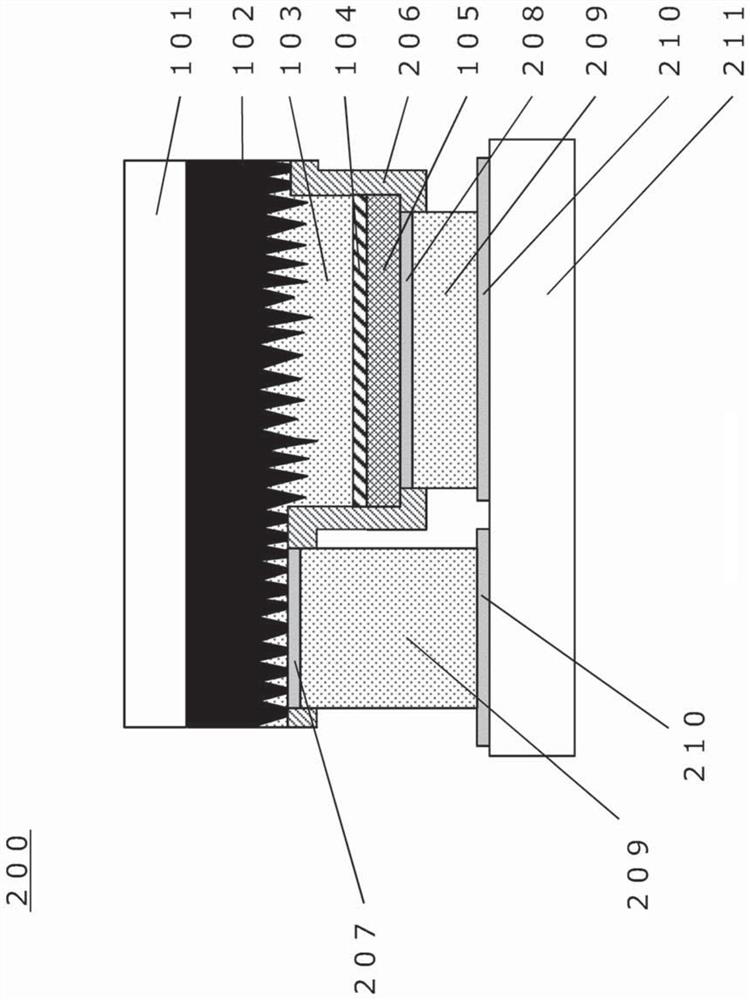

[0114] Figure 8 It is a diagram showing the configuration of a light emitting diode element 200 according to Modification 1. FIG.

[0115] The light emitting diode element 200 of Modification 1 is different from the above-mentioned embodiment in that the surface on which the n-side ohmic electrode 207 is formed is a surface where only the second n-type GaN layer 103 is exposed.

[0116] Figure 8 In this process, the etching by dry etching in the above etching step (step S12 ) is reduced so that the surface on which the n-side ohmic electrode 207 is formed is in the second n-type GaN layer 103 . For example, such a configuration may be adopted when it is desired to reduce the etching level difference by dry etching.

[0117] In the light emitting diode element 200 of this modified example, there is a possibility that the resistance may be reduced by increasing the thickness of the n-type semiconductor layer. However, on the other hand, the contact resistance of the n-side ...

Deformed example 2

[0119] Figure 9 It is a figure showing the structure of the light emitting diode element 200 of the modification 2.

[0120] The light emitting diode element 200 of Modification 2 is different from the above-mentioned embodiment in that the surface on which the n-side ohmic electrode 207 is formed is a surface where only the first n-type GaN layer 102 is exposed.

[0121] Figure 9 In this case, the surface on which the n-side ohmic electrode 207 is formed is in the first n-type GaN layer 102 . For example, when the thickness of the first n-type GaN layer 102 is sufficiently thick, or when the unevenness is small and it is difficult to stop etching at the interface, such a structure can simplify the process steps.

[0122] In the light emitting diode element 200 of this modified example, the contact resistance of the n-side ohmic electrode 207 can be reduced the most. On the other hand, however, the substrate resistance caused by the first n-type GaN layer 102 directly und...

Deformed example 3

[0124] In the above-mentioned embodiments, a scheme in which the second n-type GaN layer 103 is formed through a single crystal growth process is shown. However, when the unevenness of the first n-type GaN layer 102 is very large, it is difficult to make the surface of the second n-type GaN layer 103 completely flat, and there is a concern that some Concavity and convexity of about 100 nm. In addition, there is a concern that the thickness of the second n-type GaN layer 103 becomes too thick for planarization.

[0125] Therefore, in the process of forming the second n-type GaN layer 103 , mechanical polishing and CMP (Chemical Mechanical Polishing) may be performed on the second n-type GaN layer 103 . For example, after the second n-type GaN layer 103 is crystal-grown by the HVPE method, mechanical polishing may be performed, and the second n-type GaN layer 103 may be crystal-grown again by the MOCVD method or the like.

[0126] With such a configuration, unevenness formed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com