Milk-beer beverage and preparation method thereof

A beverage and milk beer technology, which is applied in the direction of milk preparations, bacteria and dairy products used in food preparation, etc., can solve the problems of the appearance stability of milk beer, the stability of milk beer is not improved, and the stabilizer pollutes the environment, etc. Achieve the effect of promoting intestinal digestion, improving the flavor of milk beer, saving time and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Exploring the effects of different enzyme types on milk beer

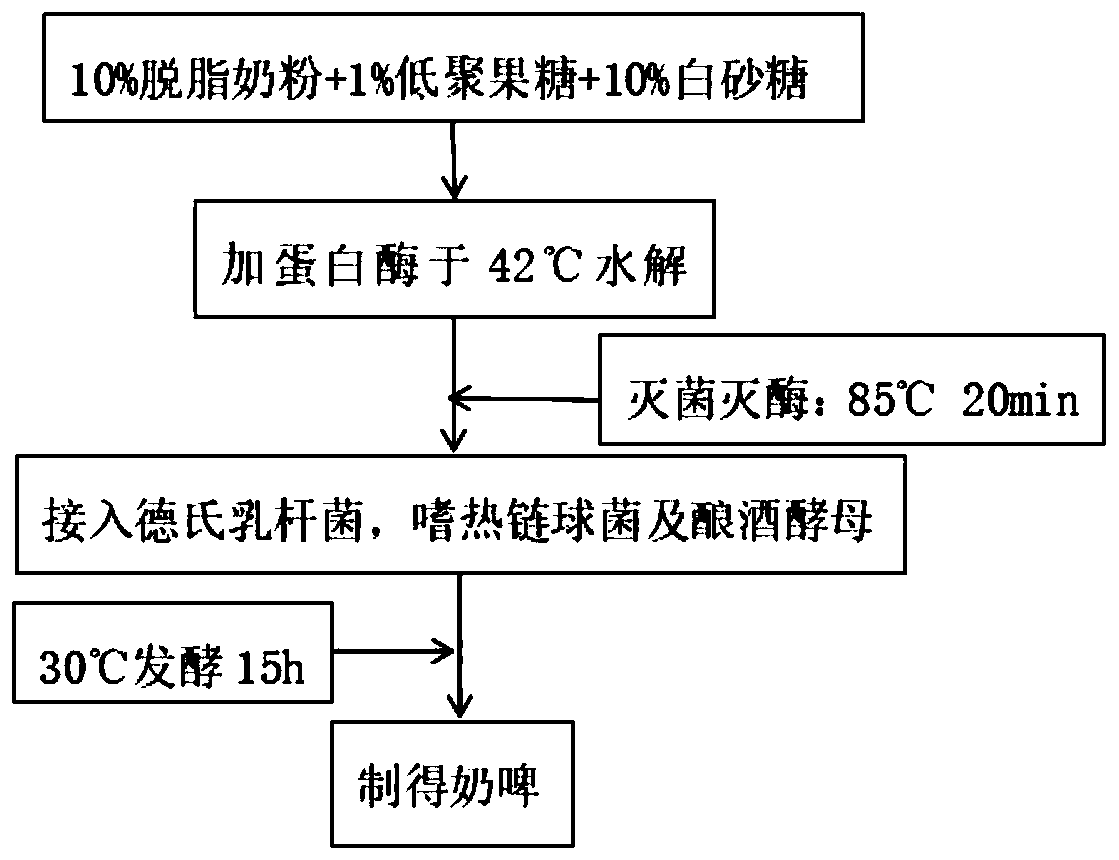

[0047] The first step is to prepare the original emulsion: dissolve in the ratio of skim milk powder: white sugar: prebiotics: water = 10:10:1:79 by mass fraction, shake well to make it fully dissolved.

[0048] The second step of enzymatic hydrolysis: when the milk is cooled to room temperature, add neutral protease, papain, and bromelain to hydrolyze for 4 hours, and the enzyme activities are all 60,000 U / 100mL.

[0049] The third step is to heat to kill the enzyme: 85°C for 20min

[0050] The fourth step is to ferment the enzymolysis solution: when it is cooled to 37°C-42°C, inoculate Lactobacillus delbrueckii and Streptococcus thermophilus for 109 CFU / 100mL, the ratio is 1:1, at the same time inoculate Saccharomyces cerevisiae 10 9 CFU / 100mL, fermented at 30°C for 15h to produce a new type of milk beer.

[0051] The fifth step is to draw 0.1mL in 100mL milk beer for gradient dilution, use MR...

Embodiment 2

[0057] Example 2: Exploring the effects of different enzyme activities on milk beer

[0058] The first step is to prepare the original emulsion: dissolve in the ratio of skim milk powder: white sugar: prebiotics: water = 10:10:1:79 by mass fraction, shake well to make it fully dissolved.

[0059] The second step of enzymatic hydrolysis: when the milk is cooled to room temperature, add neutral protease to hydrolyze for 4 hours. Ten thousand U / 100mL.

[0060] The third step is to heat to kill the enzyme: 85°C for 20min

[0061] The fourth step is to ferment the enzymolysis solution: when it is cooled to 37°C-42°C, inoculate Lactobacillus delbrueckii and Streptococcus thermophilus for 10 9 CFU / 100mL, the ratio is 1:1, at the same time inoculate Saccharomyces cerevisiae 10 9 CFU / 100mL, fermented at 30°C for 15h to produce a new type of milk beer.

[0062] The fifth step is to draw 0.1mL in 100mL of milk beer for gradient dilution, use MRS agar medium to inoculate Lactobacillus...

Embodiment 3

[0064] Example 3: Exploring the effects of different bacilli: coccus ratios on milk beer

[0065] The first step is to prepare the original emulsion: dissolve in the ratio of skim milk powder: white sugar: prebiotics: water = 10:10:1:79 by mass fraction, shake well to make it fully dissolved.

[0066] The second step of enzymatic hydrolysis: when the milk is cooled to room temperature, add neutral protease to hydrolyze for 4 hours, and the enzyme activity is 60,000 U / 100mL.

[0067] The third step is to heat to kill the enzyme: 85°C for 20min

[0068] The fourth step is to ferment the enzymolysis solution: when it is cooled to 37°C-42°C, inoculate Lactobacillus delbrueckii and Streptococcus thermophilus for 10 9 CFU / 100mL, bacillus: coccus ratio of 10:1, 5:1, 2:1, 1:1, 1:2, 1:5, 1:10, simultaneously inoculate Saccharomyces cerevisiae 10 9 CFU / 100mL, fermented at 30°C for 15h to produce a new type of milk beer.

[0069] The fifth step is to draw 0.1mL in 100mL of milk beer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com