Making method of antioxidant egg white peptide and enzymolysis defoaming device

A technology of anti-oxidation and production methods, applied in chemical instruments and methods, foam dispersion/prevention, mixers with rotating stirring devices, etc., can solve the problems of affecting the utilization rate of protein, easy to solidify when heated, and limit applications, etc., to achieve Improved thermal stability, improved enzymatic hydrolysis effect, and high antioxidant activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

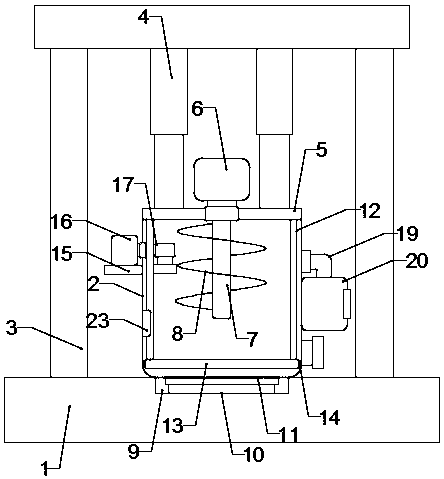

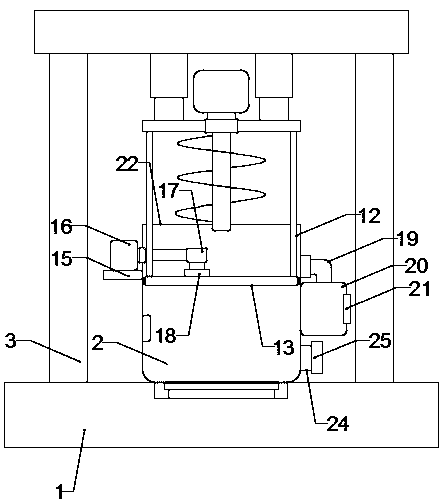

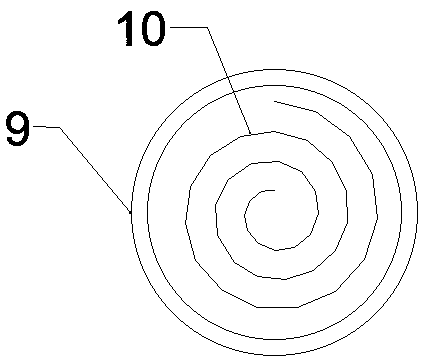

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing antioxidant egg white polypeptide, the specific steps comprising:

[0037] Step 1: Select fresh eggs within three days of the date that the farm has no antibiotic residues, wash and sterilize them, beat the eggs and separate them, and take out the egg whites;

[0038] Step 2, take 1000 kg of egg white liquid and pass it through a 100-mesh sieve, and measure that the weight of the solid matter accounts for 10%, and adjust the pH of the egg white liquid to pH 8.0 with a citric acid solution with a volume ratio of 40%;

[0039] Step 3, heat up the egg white liquid to 55°C and keep it for 30 minutes;

[0040] Step 4, add heat-resistant protease THERMOASE PC10F0.2kg, the addition amount is 0.2% of the weight of the solid, stir while adding, and remove the foam generated on the surface of the liquid in time;

[0041] Step 5: Raise the temperature of the reaction system to 62°C, at this time, the solution is yellowish-brown and clear, and the enzymatic ...

Embodiment 2

[0045] A method for preparing antioxidant egg white polypeptide, the specific steps comprising:

[0046] Step 1: Select fresh eggs within three days of the date that the farm has no antibiotic residues, wash and sterilize them, beat the eggs and separate them, and take out the egg whites;

[0047] Step 2, take 1000 kg of egg white liquid and pass it through a 100-mesh sieve, and measure that the weight of the solid matter accounts for 10%, and adjust the pH of the egg white liquid to pH 8.0 with a citric acid solution with a volume ratio of 40%;

[0048] Step 3, heat up the egg white liquid to 55°C and keep it for 30 minutes;

[0049] Step 4, add heat-resistant protease THERMOASE PC10F0.4kg, the addition amount is 0.4% of the weight of the solid, stir while adding, and remove the foam generated on the surface of the liquid in time;

[0050] Step 5: Raise the temperature of the reaction system to 68°C, at this time, the solution is yellowish-brown and clear, and the enzymatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com