Method for treating flue gas pollutants through chemical oxidation absorption

A technology for chemical oxidation and pollutants, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems that the absorption liquid cannot be recycled and the denitrification efficiency cannot exceed 66.67%, so as to improve the effective utilization rate, Cost savings, power consumption, and quantity reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

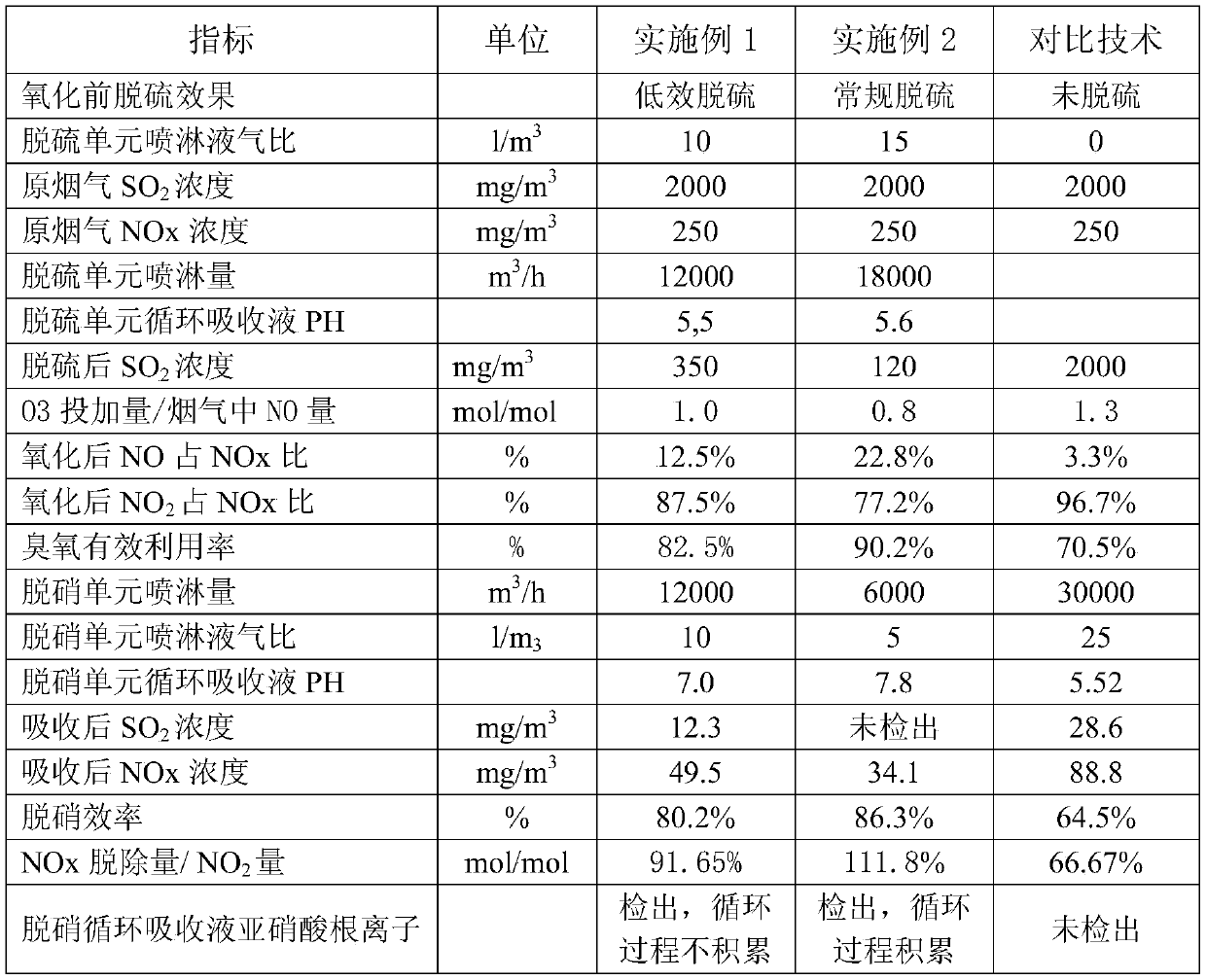

[0042] Flue gas treatment process 1:

[0043] A 360 square meter sintering machine with a flue gas volume of 1,200,000Nm 3 / h, flue gas SO 2 Concentration 2000mg / m 3 , NOx concentration 250mg / m 3 (in NO 2 total), of which NO accounts for 95%; NO 2 accounting for 5%. It is required to reach SO after flue gas treatment 2 Concentration 30mg / m 3 , NOx concentration 50mg / m 3 (in NO 2 meter) emission standards. The desulfurization unit adopts lime-gypsum wet flue gas desulfurization process, the oxidation unit uses ozone as the oxidant, and the absorption unit uses calcium hydroxide suspension as the circulating absorption liquid.

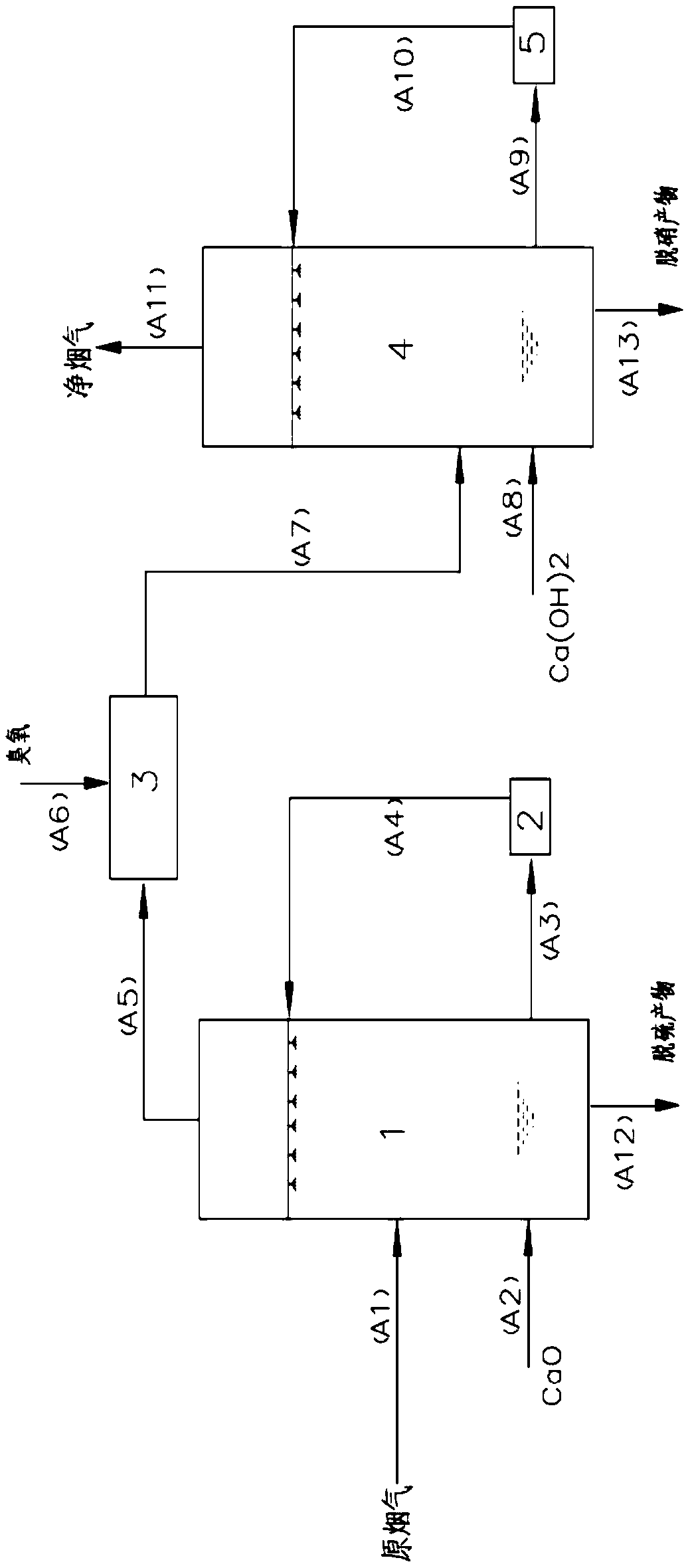

[0044] Its flue gas treatment process flow (process flow 1,) is as follows (see attached figure 1 ): Contains SO 2 The original flue gas with NOx enters the desulfurization unit (1) from the pipeline 1 (A1), the desulfurization agent calcium oxide enters the desulfurization unit (1) from the pipeline 2 (A2), and the desulfurization circulatin...

Embodiment 3 and 4

[0056] Flue gas treatment process 2:

[0057] A flat glass furnace with a flue gas volume of 120,000Nm 3 / h: flue gas SO 2 Concentration 1500mg / m 3 , NOx concentration 2500mg / m 3 (in NO 2 count). Requirements to reach SO 2 Concentration 30mg / m 3 , NOx concentration 400mg / m 3 (in NO 2 meter) emission standards. The desulfurization unit adopts the circulating fluidized bed dry flue gas desulfurization process, the oxidation unit uses hydrogen peroxide (Example 3) and the mixture of hydrogen peroxide and ozone (Example 4) as the oxidant, and the absorption unit uses sodium hydroxide solution as the circulating absorption liquid.

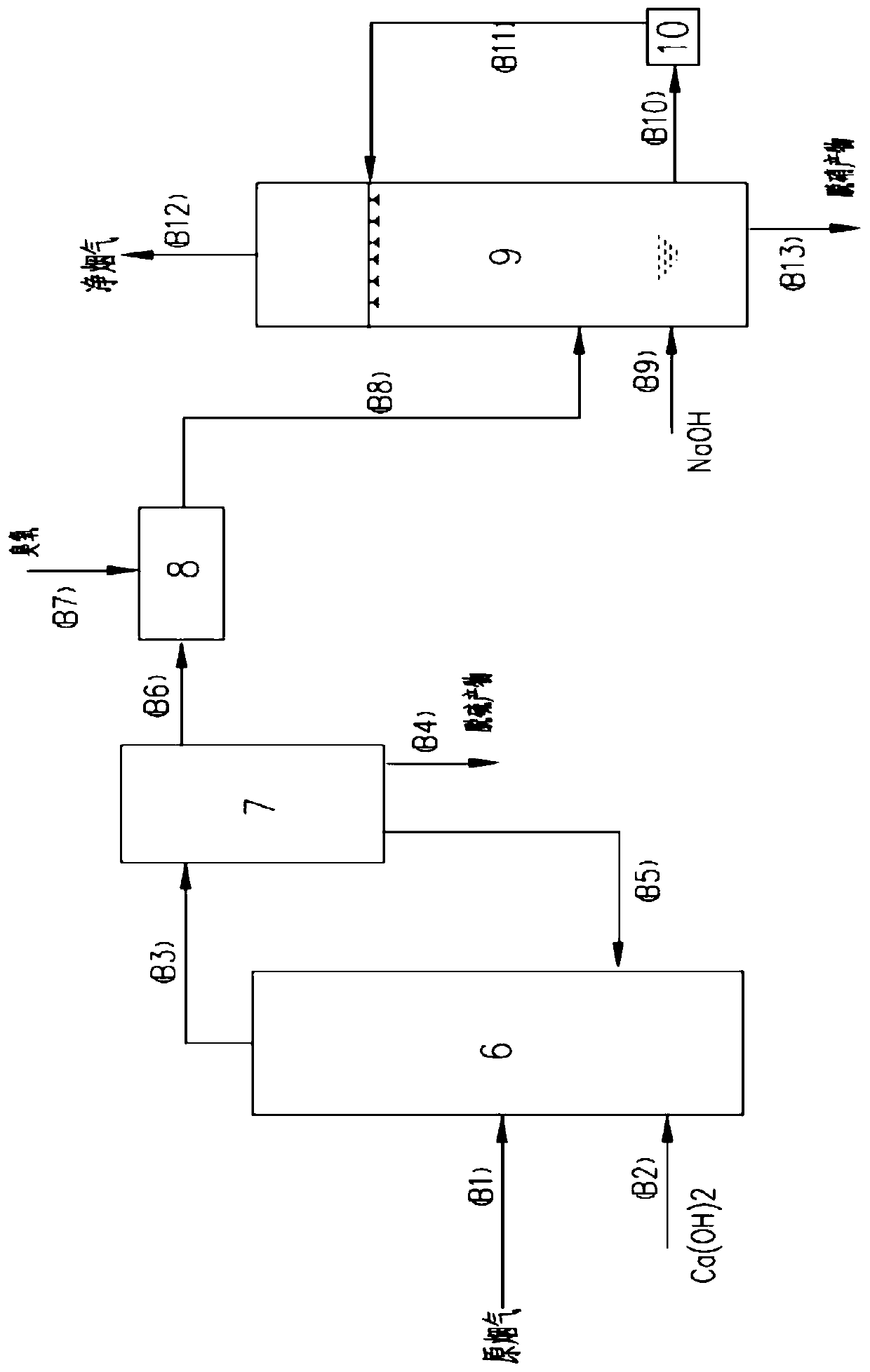

[0058] Its flue gas treatment process flow (process flow 2) is as follows (see attached figure 2 ): Contains SO 2 The original flue gas with NOx enters the desulfurization tower (6) through the pipeline B1 (B1), and the desulfurization agent calcium hydroxide particles enter the desulfurization tower (6) through the pipeline B2 (B2), and abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com