Bismuth nanowire with thickness of 1.5 nm and preparation method and application thereof

A technology of bismuth nanometer and bismuth chloride, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low Faradaic efficiency, high overpotential, etc., and achieve the effect of excellent catalytic reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 1mmol of bismuth chloride, add it to 100mL of ethylene glycol ether solution, stir ultrasonically until the solution is clear, and place it in an oil bath; then, under the protection of inert gas, raise the temperature to 80°C and stir for 30min, add 0.05 mmolNaI solution, then heated up to 160 ° C for 30 minutes, cooled to room temperature, placed in an ultrasonic instrument to stir and ultrasonically, and at the same time, quickly added 50 mmol high-concentration NaBH 4 The reducing solution forms a black-gray dispersion; after that, it is collected by filtration and washing three times with ethanol and water, and finally placed in a vacuum oven at 50° C. to dry overnight to obtain 1.5 nm-thick Bi nanowires.

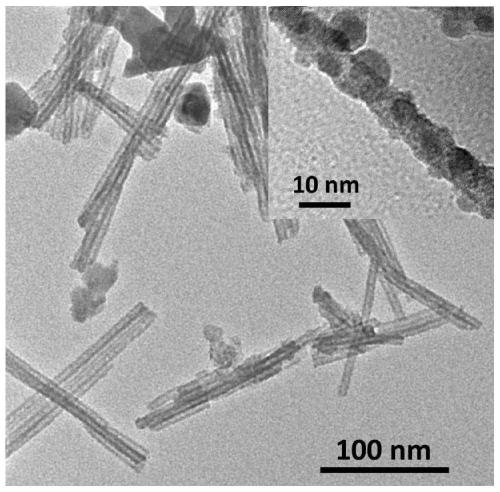

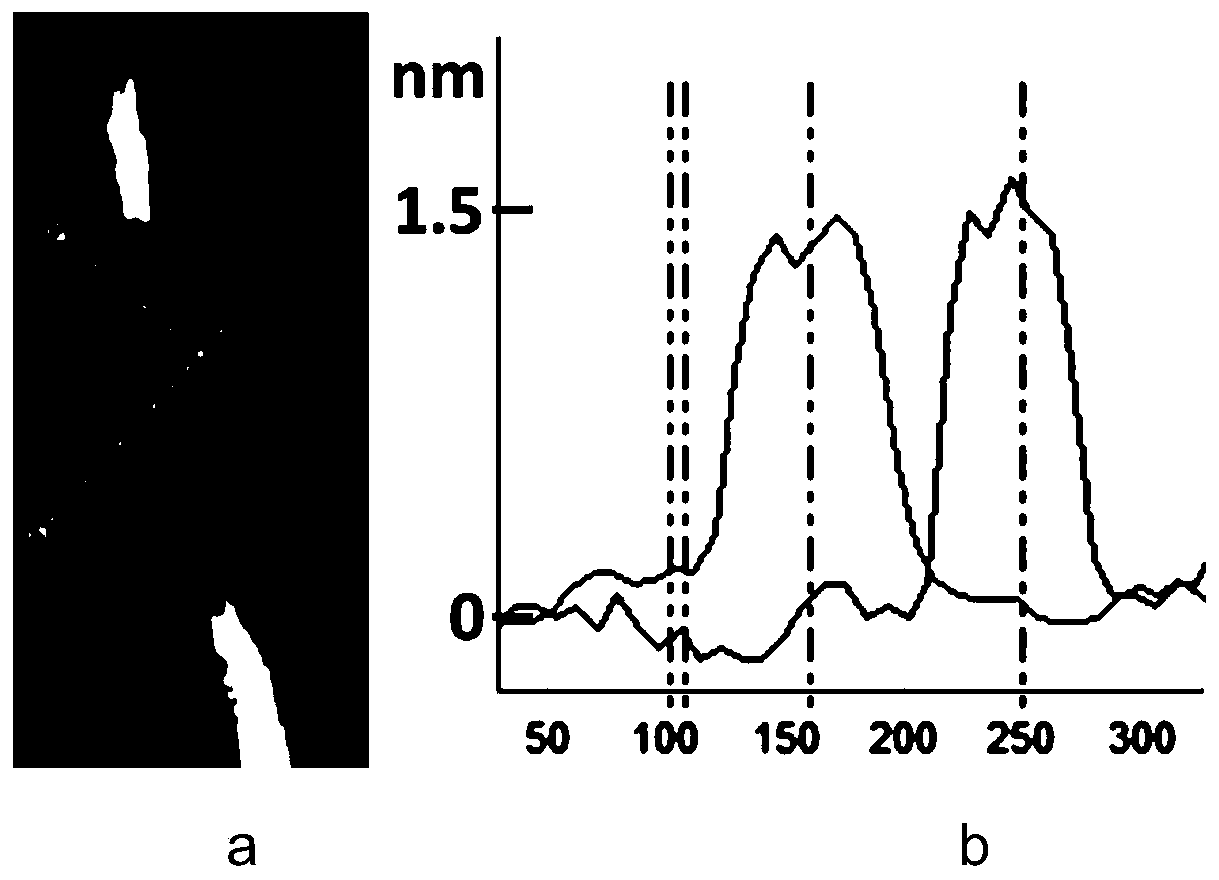

[0027] figure 1 It is a transmission electron microscope image of different magnifications of the bismuth nanowires synthesized in Example 1 of the present invention. It can be seen from the images that the material synthesized by this method presents an u...

Embodiment 2

[0030] Weigh 1 mmol of bismuth chloride, add it to 100 mL of ethylene glycol ether solution, stir ultrasonically until the solution is clear, and place it in an oil bath; then, under the protection of an inert gas, raise the temperature to 60°C and stir for 30 minutes, add 0.05 mmolNaI solution, then heated up to 140 ° C for 30 minutes, cooled to room temperature, placed in an ultrasonic instrument to stir and sonicate, and at the same time, quickly added 50 mmol high-concentration NaBH 4 The reducing solution forms a black-gray dispersion; after that, it is collected by filtration and washing three times with ethanol and water, and finally placed in a vacuum oven at 50° C. to dry overnight to obtain 1.5 nm-thick Bi nanowires.

Embodiment 3

[0032] Weigh 3 mmol of bismuth chloride, add it to 200 mL of ethylene glycol ether solution, stir ultrasonically until the solution is clear, and place it in an oil bath; then, under the protection of an inert gas, raise the temperature to 80°C and stir for 40 minutes, add 0.05 mmolNaI solution, then heated up to 160 ° C for 40 minutes, cooled to room temperature, placed in an ultrasonic instrument to stir and ultrasonically, and at the same time quickly added 60 mmol high-concentration NaBH 4 The reducing solution forms a black-gray dispersion; after that, it is collected by filtration and washing three times with ethanol and water, and finally placed in a vacuum oven at 50° C. to dry overnight to obtain 1.5 nm-thick Bi nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com