A method for preparing two-dimensional cobalt-aluminum composite oxides with hydrotalcite and its application

A composite oxide, hydrotalcite technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, water pollutants, etc., can solve the problem of difficult to obtain large-area two-dimensional layered materials, organic The problems of low degradation rate of pollutants and poor catalytic performance can achieve the effects of simple preparation process, suppression of collapse, and mild preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

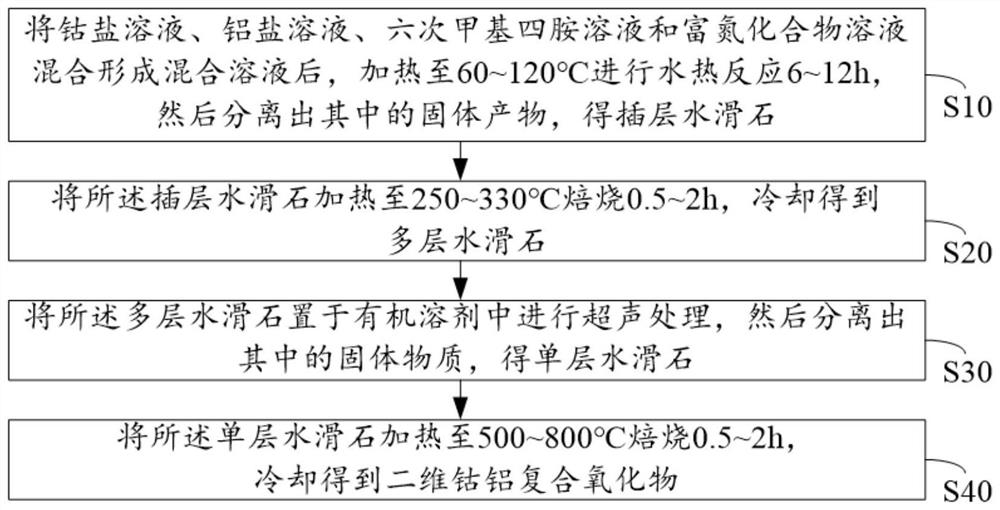

Method used

Image

Examples

Embodiment 1

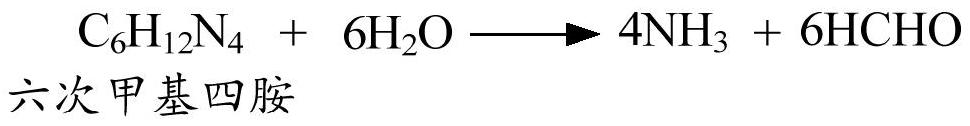

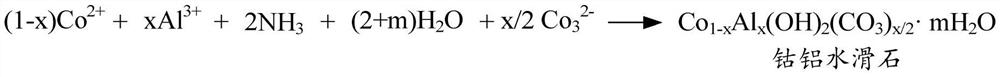

[0057] (1) CoCl of 0.01mol / L2 Solution, 0.01mol / L of AlCl 3 Solution, 0.03mol / L of six-time methyltetraamine solution and 0.01mol / L melamine solution are mixed sequentially according to the volume ratio of 1:3:5:0.5 to form a mixture; Then the mixture is heated to 80 °C for hydrothermal reaction for 12h, after the reaction is completed, the solid products are separated, washed and dried, and the water talc is inserted;

[0058] (2) The prepared intercalation hydrotalgalc is heated to 330 °C at a heating rate of 5 °C / min in an air atmosphere, and then heated to room temperature after the end of insulation, and multi-layer hydrotalga is supernatural;

[0059] (3) The prepared multilayer hydrotalx is put into 50mL formamide, sonicated for 6h under the conditions of 40Hz and 25 °C, and then the solid substances are separated, washed and dried to obtain a single layer of hydrotalcite;

[0060] (4) The prepared single-layer water talc is heated to 600 ° C in the air atmosphere and kept ...

Embodiment 2

[0062] (1) The CoCl of 0.02mol / L will be placed 2 Solution, 0.03mol / L of AlCl 3 The solution, 0.01mol / L of the sixth methyltetraamine solution and the 0.01mol / L melamine solution are mixed sequentially according to the volume ratio of 1:1:2:1 to form a mixture; Then the mixture is heated to 120 °C for hydrothermal reaction for 6h, after the reaction is completed, the solid products are separated, washed and dried, and the water talc is inserted;

[0063] (2) The prepared intercalation hydrotalgalc is heated to 300 °C at a heating rate of 3 °C / min in an air atmosphere, and then heated to 0.5h after heat preservation, and naturally cooled to room temperature after the end of insulation, with multiple layers of hydrotalgalc;

[0064] (3) The prepared multilayer hydrotalgalc is put into 80mL of formamide, sonicated for 3h under the conditions of 50Hz and 30 °C, and then the solid substances are separated, washed and dried to obtain a single layer of hydrotalcite;

[0065] (4) The prep...

Embodiment 3

[0067] (1) CoCl of 0.05mol / L2 Solution, 0.05mol / L AlCl 3 The solution, 0.12 mol / L of the sixth methyltetraamine solution and the 0.02mol / L melamine solution are mixed sequentially according to the volume ratio of 1:1:2:0.5 to form a mixture; Then the mixture is heated to 110 °C for hydrothermal reaction for 8h, after the reaction is completed, the solid products are separated, washed and dried, and the water talc is inserted;

[0068] (2) The prepared intercalation hydrotalgalc is heated to 280 °C at a heating rate of 2 °C / min in an air atmosphere, and after the insulation is ended, it is naturally cooled to room temperature, and multiple layers of hydrotalite are heated;

[0069] (3) The prepared multilayer hydrotalcite is put into 60mL of formamide, sonicated at 60Hz, 20 °C for 8h, and then the solid substances are separated, washed and dried to obtain a single layer of hydrotalcite;

[0070] (4) The prepared single-layer water talc is heated to 650 °C in an air atmosphere and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com