Preparation method and application of carbon-sulfur doped zero-valent iron composite material

A composite material and zero-valent iron technology, applied in the field of environmental restoration, can solve the problems of large amount of waste water and waste gas discharge, high cost and large-scale production, etc., and achieve the effect of high activity, low cost of raw materials and abundant sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

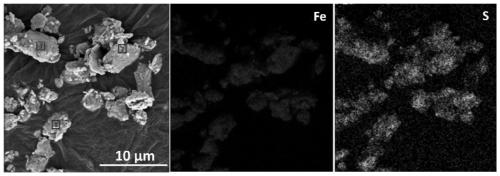

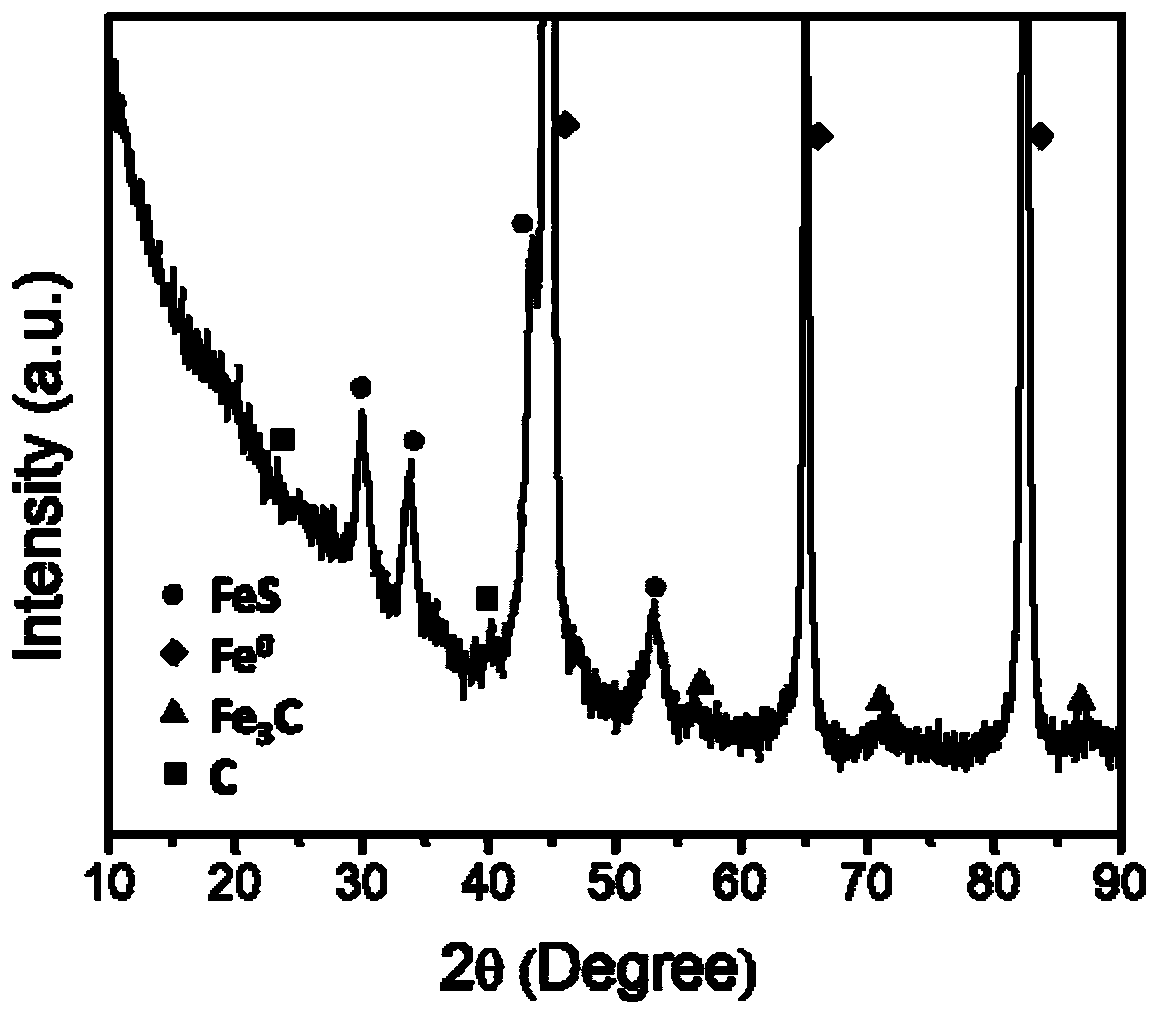

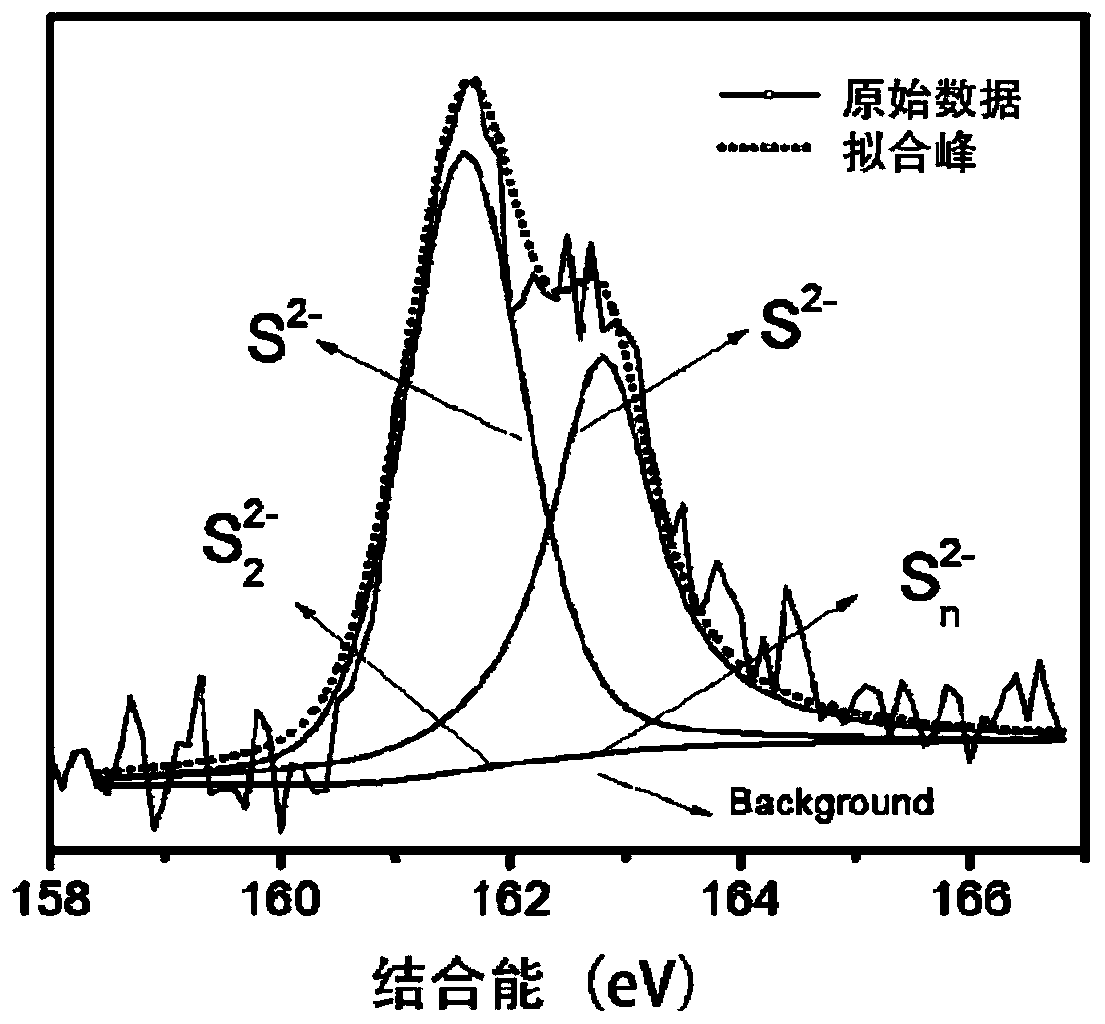

[0054] A planetary ball mill (dry ball mill) is used to prepare a carbon-sulfur doped zero-valent iron composite material, and the steps are as follows:

[0055] (1) Filling zirconia ball milling beads (6mm in particle size) into the ball milling jar as the ball milling medium, the filling amount is 20% of the volume of the ball milling jar;

[0056] (2) Fill 0.134g elemental sulfur powder and 2.341g iron powder (particle size less than 1mm) and 0.025g biochar powder particles (particle size is less than 1mm) (mass fractions are 5.3%, 93.7%, 1% respectively) Mix in the ball mill tank and fill the tank with nitrogen;

[0057] (3) Adjust the rotation speed of the ball mill to 500rpm, and continue ball milling for 20 hours;

[0058] (4) Under the condition of nitrogen protection, the ball milling medium and the ball milling product are separated by a screen to obtain a carbon-sulfur-doped zero-valent iron composite material.

[0059] The activity of the above materials was test...

Embodiment 2

[0062] A sand mill (wet ball mill) is used to prepare a carbon-sulfur doped zero-valent iron composite material, and the steps are as follows:

[0063] (1) Filling zirconia ball milling beads (0.3-0.4 mm in particle size) into the ball milling chamber as the ball milling medium, the filling amount being 20% of the volume of the ball milling chamber;

[0064] (2) 13.4g elemental sulfur powder and 234.1g iron powder (particle size is less than 1mm) and 2.5g biochar powder particles (particle size is less than 1mm) (mass fraction is respectively 5.3%, 93.7%, 1%) into In the mixer, and add 20L ethanol as ball milling solvent;

[0065] (3) Adjust the linear speed of the ball mill to 13m / s, and continue ball milling for 20 hours;

[0066] (4) After the ball milling is completed, a magnet is used to separate the ball milling solvent from the ball milling product to obtain a carbon-sulfur-doped zero-valent iron composite material.

[0067] The activity of the above materials was t...

Embodiment 3

[0070] This embodiment is tested with reference to Example 1, using a planetary ball mill, and the ball milling raw materials are biochar (particle diameter less than 1mm), reduced iron powder (particle diameter less than 1mm), elemental sulfur powder, other technical parameters and results are shown in the following table Show:

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com