Water-based waterproof coating with heat insulation and sound insulation functions and preparation method thereof

A heat-insulating, sound-insulating, and waterproof coating technology, which is applied in the field of functional environmental protection coatings, can solve problems such as poor crack resistance, inability to protect materials, no sound insulation, and heat insulation, etc., to achieve improved bonding strength, good promotion prospects, and leveling properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a kind of preparation method of the described water-based waterproof coating with heat and sound insulation function, comprising the following steps:

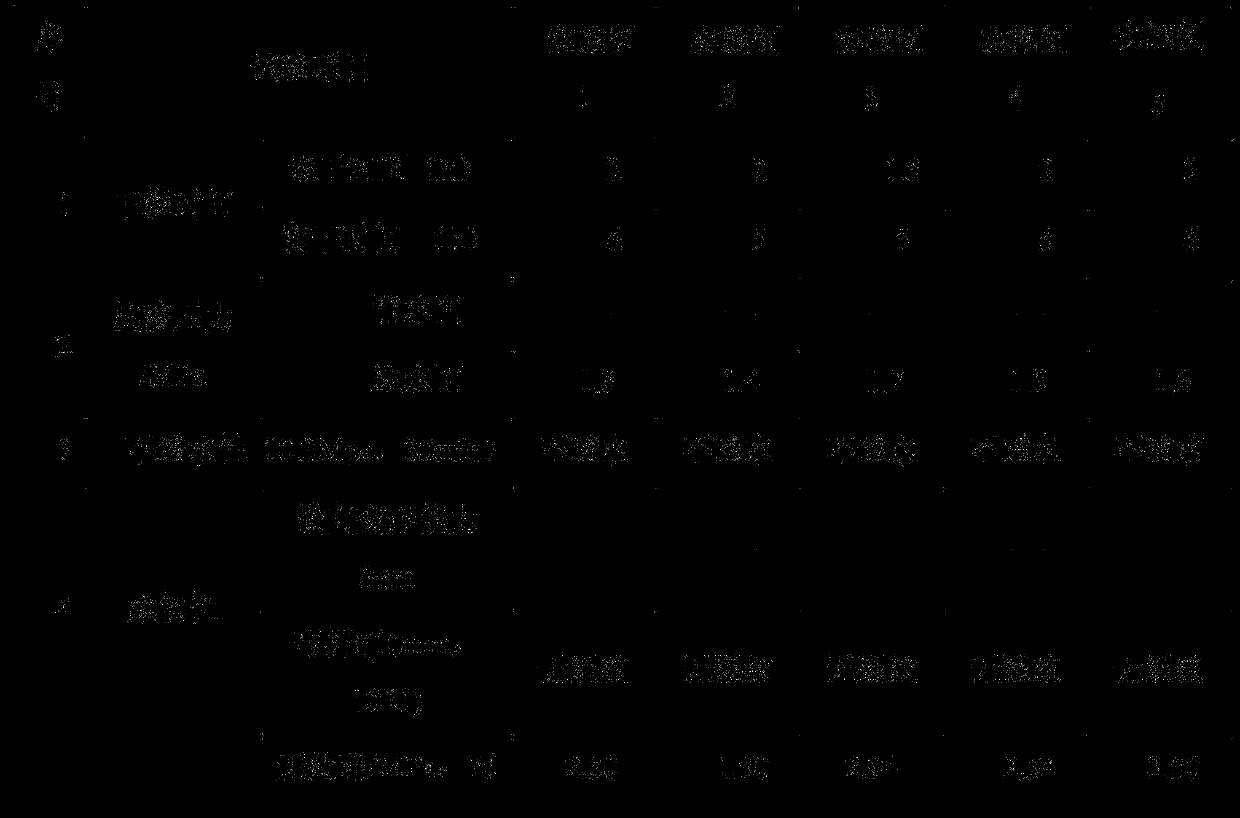

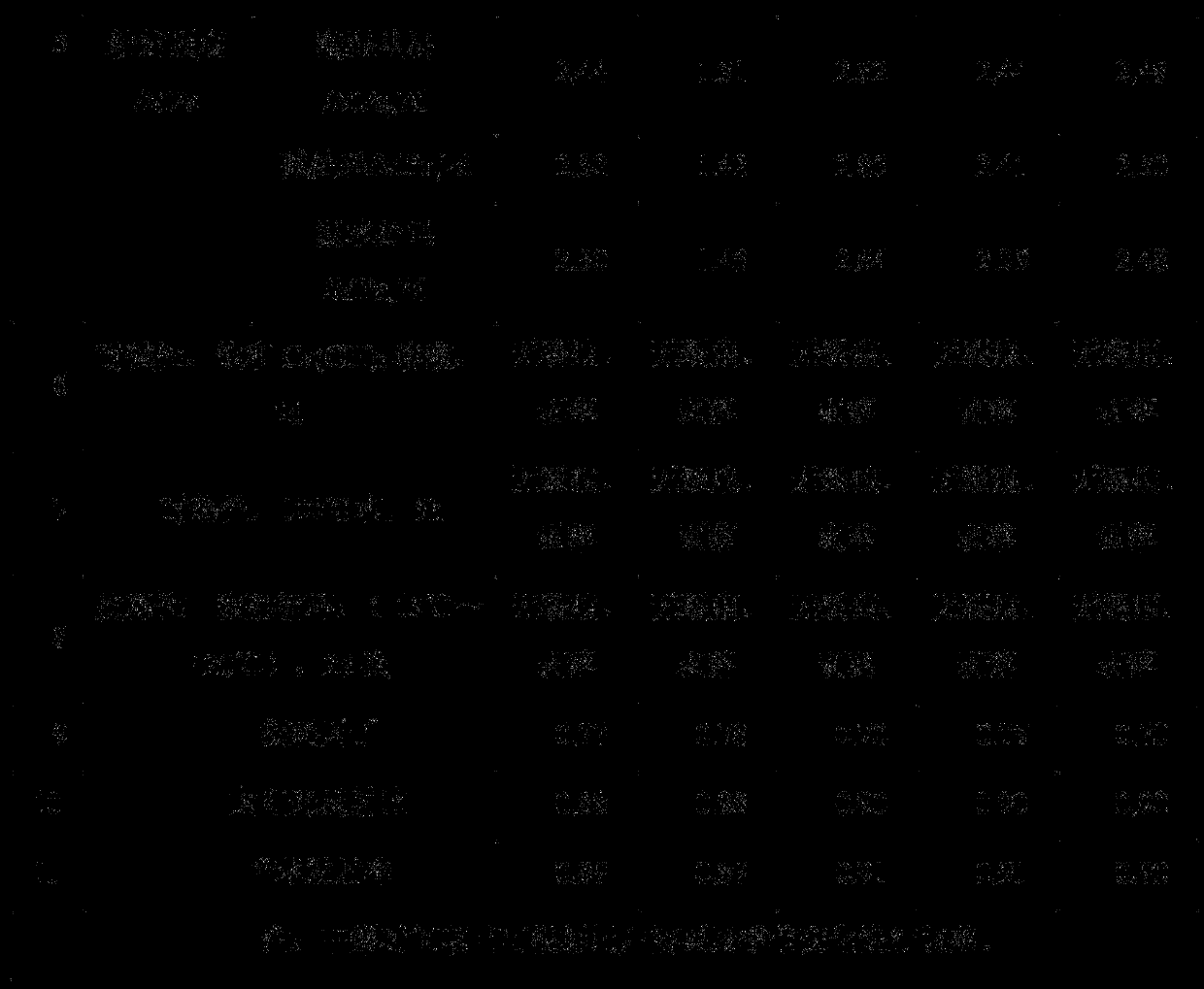

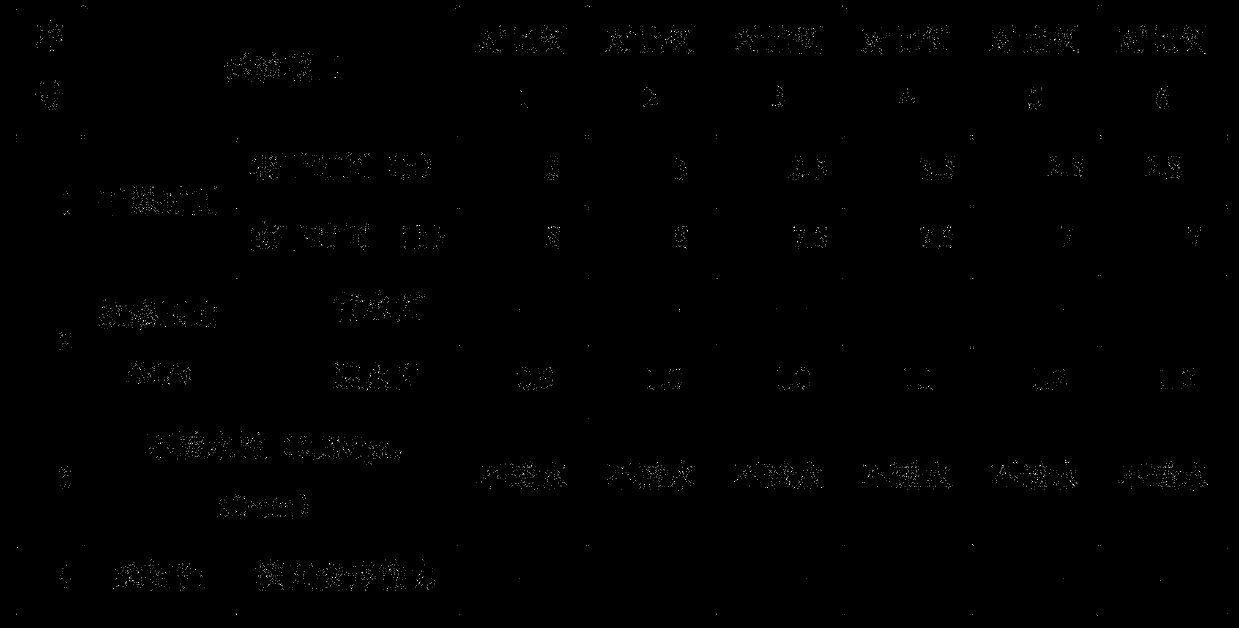

[0046] Step 1: Take 35-55 parts of cement, 35-45 parts of quartz sand, 1-5 parts of quartz powder, 10-15 parts of modified heat insulation material, 5-10 parts of modified sound insulation material, fiber 0.02 to 0.05 parts of plain ether and 0.4 to 0.5 parts of water reducing agent are respectively put into a superfine pulverizer, mixed and pulverized to superfine powder to obtain powder;

[0047] Step 2: Take 25-30 parts of styrene-acrylic emulsion No.1 and 25-30 parts of styrene-acrylic emulsion No. Stir for 15-20min under the condition of min;

[0048] Step 3: Weigh 0.10-0.20 parts of preservatives, 0.20-0.30 parts of dispersants, and 0.10-0.20 parts of defoamers, respectively, and add them to the material preparation tank after stirring in step 2, and stir at a high speed of 800-...

Embodiment 1

[0053] A water-based waterproof coating with heat and sound insulation functions, its raw materials are composed of liquid material and powder, and the liquid material and powder are composed of a weight ratio of 1:3;

[0054] Wherein, the liquid material is composed of the following raw materials in parts by weight: 25 parts of styrene-acrylic emulsion No. 1, 25 parts of styrene-acrylic emulsion No. 0.10 parts of agent, 40 parts of deionized water;

[0055] The powder is composed of the following raw materials in parts by weight: 35 parts of ordinary portland cement with the label No. 42.5, 35 parts of quartz sand, 1 part of quartz powder, 10 parts of modified heat insulating material (i.e. hollow glass microspheres), Modified sound insulation material (that is, nitrile rubber powder and activated carbon mixed at a weight ratio of 60:40) 5 parts, hydroxyethyl methyl cellulose ether 0.02 part, sulfonated melamine superplasticizer 0.4 part.

[0056] Concretely, a kind of prepa...

Embodiment 2

[0062] A water-based waterproof coating with heat and sound insulation functions, its raw material is composed of liquid material and powder material, and the liquid material and powder material are composed of a weight ratio of 1:3.7;

[0063] Wherein, the liquid material is composed of the following raw materials in parts by weight: 27 parts of styrene-acrylic emulsion No. 1, 25 parts of styrene-acrylic emulsion No. 0.10 parts of agent, 45.6 parts of deionized water;

[0064] The powder is composed of the following raw materials in parts by weight: 50 parts of ordinary Portland cement with the label 42.5R, 39 parts of quartz sand, 3 parts of quartz powder, and 12 parts of modified heat insulating material (i.e. hollow glass microspheres). 6.5 parts of modified sound insulation material (that is, nitrile rubber powder and activated carbon mixed in a weight ratio of 60:40), 0.03 part of hydroxyethyl methyl cellulose ether, and 0.4 part of sulfonated melamine superplasticizer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com