Sizing material for sealing gasket, sealing gasket, preparation method of sealing gasket and plate heat exchanger comprising sealing gasket

A technology for sealing gaskets and rubber materials, applied in the field of sealing rubber, can solve the problems of poor fluidity, uneven thickness of sealing gaskets, easy tearing when demoulding, etc., and achieves good fluidity, which is conducive to industrialized large-scale production and easy to remove. mod effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] According to one aspect of the present invention, a kind of preparation method of above-mentioned sealing gasket, described preparation method comprises the following steps:

[0085] Mixing EPDM rubber, dendritic polymer, vulcanizing agent and optional auxiliary agent to obtain a mixed rubber, and then vulcanizing the mixed rubber to obtain a sealing gasket.

[0086] The preparation method of the sealing gasket provided by the invention, the preparation method first mixes EPDM rubber, dendritic polymer, vulcanizing agent and optional auxiliary agent to obtain the mixed rubber, and then vulcanizes the mixed rubber , to get the sealing gasket. The preparation method has the advantages of simple preparation process, easy control of processing flow, and favorable industrialized large-scale production.

[0087] In a preferred embodiment of the present invention, the kneading method is as follows: the EPDM rubber is first masticated and then mixed with dendritic polymer, vul...

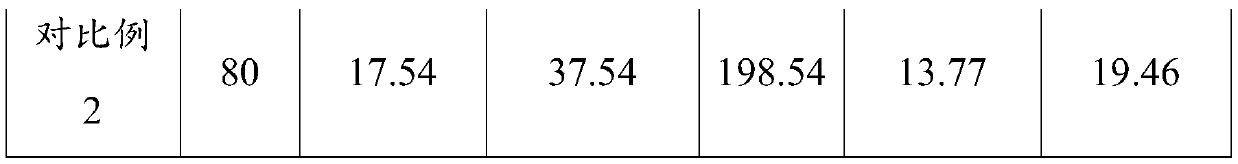

Embodiment 1

[0107] A sealing gasket, the sealing gasket is prepared from a rubber compound for the sealing gasket, and the rubber compound for the sealing gasket is made from the following raw materials:

[0108] 80 parts of EPDM rubber, 55 parts of PUREX brand HS22 carbon black, 35 parts of natural gas semi-reinforced carbon black, 2 parts of zinc oxide, 4 parts of vulcanizing agent DHBP-45, 0.5 parts of crosslinking agent TM-60, antioxidant 0.2 part of DFC-34, 6 parts of antioxidant MMB and 1 part of dendritic polymer;

[0109] The preparation method of the sealing gasket is as follows:

[0110] (1) Open mill plastication: Weigh the EPDM rubber by the number of parts, adjust the roll distance of the open mill to 1mm, and thinly pass the EPDM material on the open mill for 5 times to make triangular bags;

[0111] (2) Kneading by kneader: park the masticated EPDM material for 12 hours, add it to the kneader, and add the rest of the raw materials according to the corresponding components,...

Embodiment 2

[0117] A sealing gasket, the sealing gasket is prepared from a rubber compound for the sealing gasket, and the rubber compound for the sealing gasket is made from the following raw materials:

[0118] 120 parts of EPDM rubber, 75 parts of PUREX brand HS22 carbon black, 35 parts of natural gas semi-reinforced carbon black, 8 parts of zinc oxide, 9 parts of vulcanizing agent DHBP-45, 5 parts of crosslinking aid TM-60, antioxidant 5 parts of DFC-34, 0.4 part of antioxidant MMB and 6 parts of dendrimer;

[0119] The preparation method of the sealing gasket is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com