Preparation method of composite material with high dielectric constant and low dielectric loss

A technology of high dielectric constant and composite materials, which is applied in the field of preparation of three-phase dielectric composite materials, can solve the problems of polymer flexibility damage, affect the application effect of materials, increase the cost of materials, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

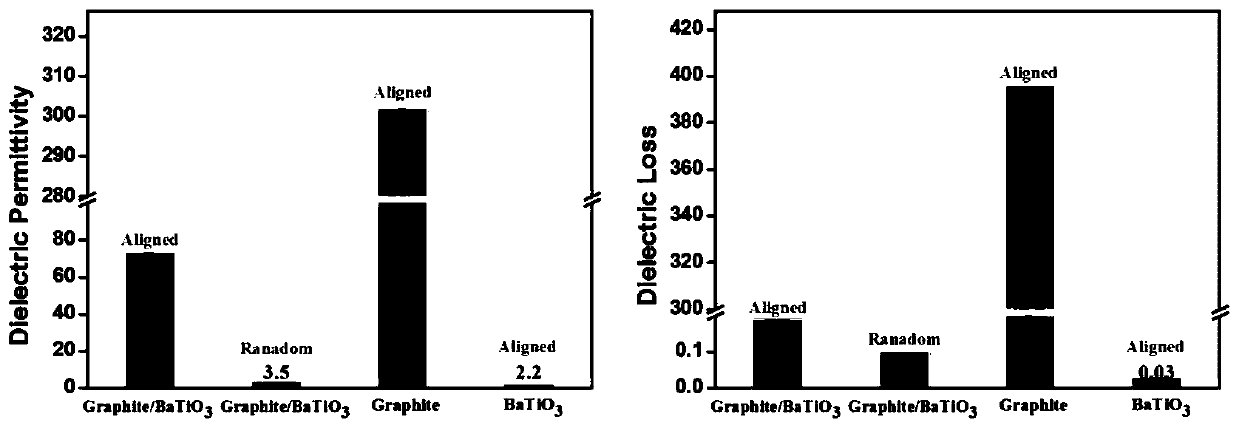

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments. The described embodiments are only preferred embodiments of the present invention, and are not used to limit the present invention. Various modifications and changes are possible in the present invention. Any modification, equivalent replacement, improvement, etc., made within the spirit and principle of the present invention shall be included in the protection scope of the present invention.

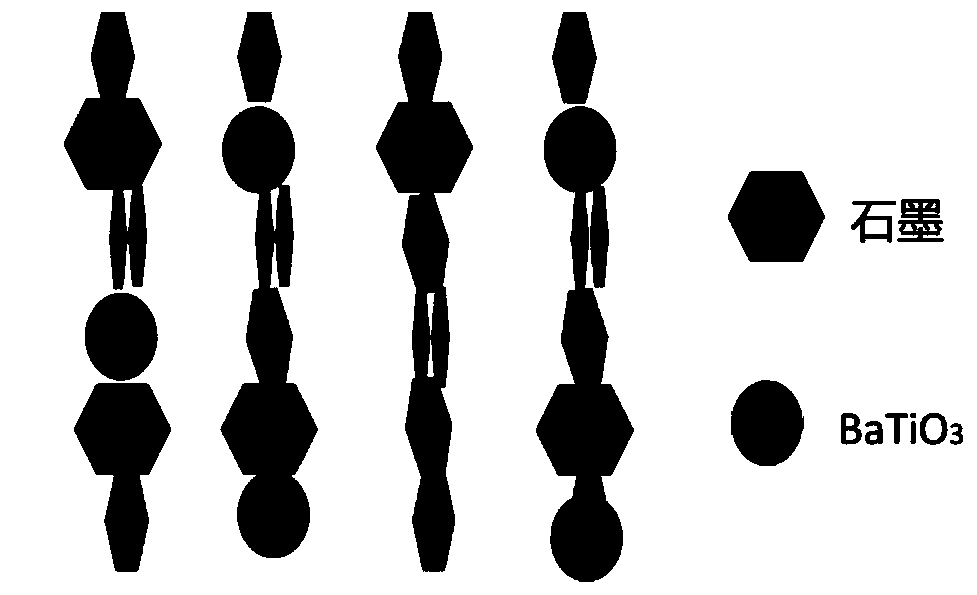

[0020] In this embodiment, 12000 mesh graphite is used as the conductive filler, barium titanate is used as the ceramic filler, the matrix is Dow Corning 184 polydimethylsiloxane (PDMS), and the selected external field is an electric field.

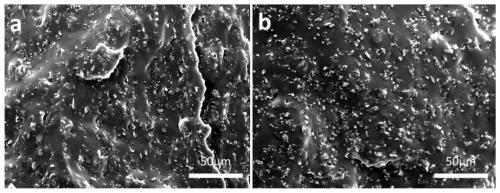

[0021] A graphite / barium titanate / PDMS mixture with 2.5% graphite mass fraction and 5% barium titanate mass fraction was prepared. In order to achieve uniform mixing and remove bubbles, a non-interventional homogenizer was used for 3min stirring trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com