Phosphogypsum-based fabricated exterior wallboard and preparation method thereof

A technology for phosphogypsum and exterior wall boards, which is applied in the field of building wall materials, can solve the problems of low strength, limited application, and high water absorption, and achieves the effects of low water absorption, reduced building weight, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

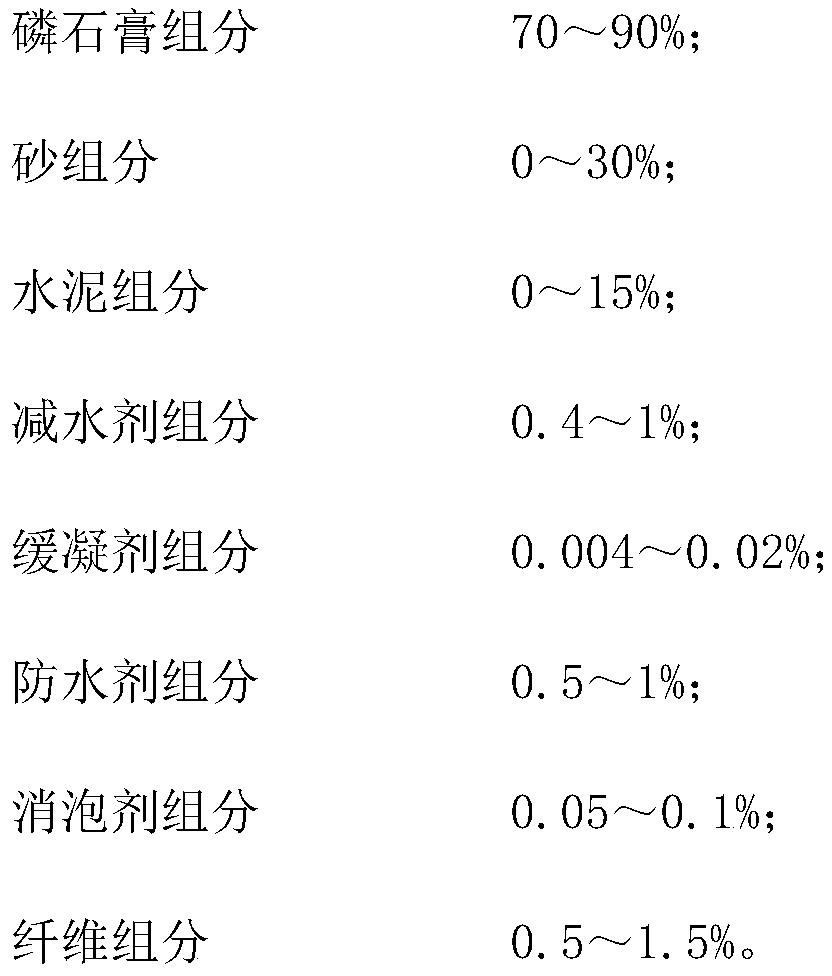

[0016] The phosphogypsum-based fabricated exterior wallboard provided in this embodiment includes phosphogypsum components, sand components, cement components, water reducing agent components, retarder components, waterproofing agent components, defoamer components and fiber component; here, the water reducing agent component uses polycarboxylate water reducing agent, the retarder component adopts protein gypsum retarder, and the waterproofing agent component adopts silicone waterproofing agent, such as silicone oil waterproofing agent; The foaming agent component adopts silicone defoamer; the fiber component adopts alkali-resistant glass fiber with a length of 2-5 cm. The weight percent of each component is:

[0017]

[0018] Weigh the required phosphogypsum component, sand component, cement component, water reducer component, retarder component and waterproofing agent component according to the weight percentage of the above-mentioned components and mix them to obtain the...

Embodiment 2

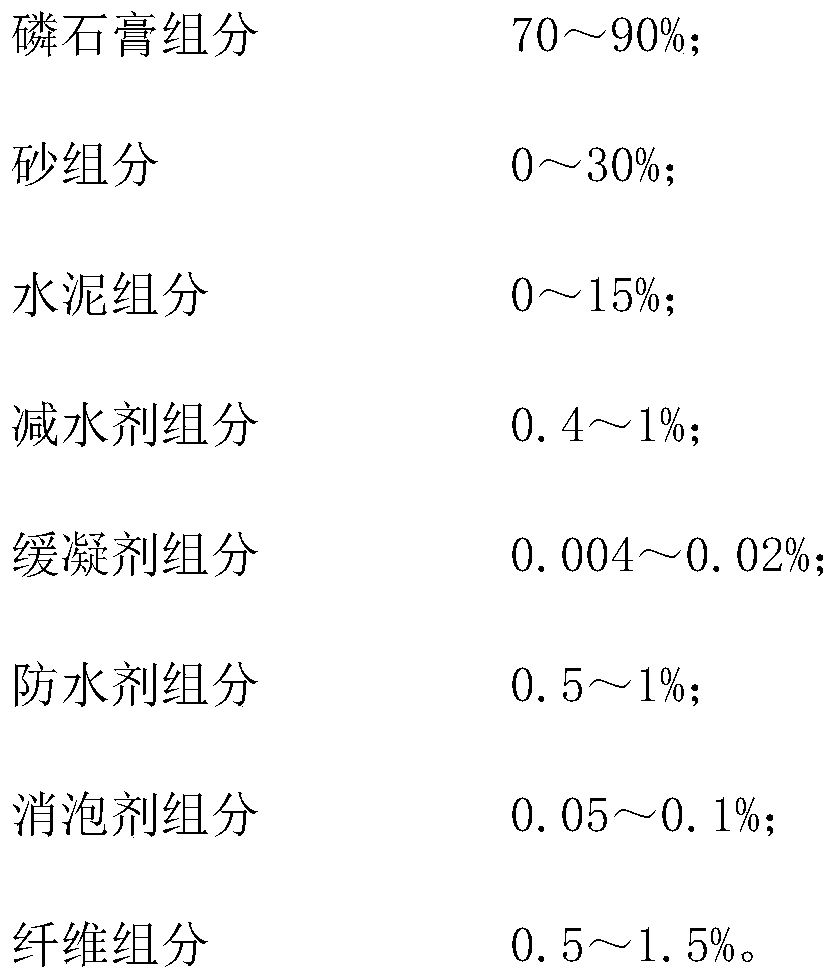

[0021] The phosphogypsum-based fabricated exterior wallboard provided in this embodiment includes phosphogypsum components, sand components, cement components, water reducing agent components, retarder components, waterproofing agent components, defoamer components and fiber component; here, the water reducing agent component uses polycarboxylate water reducing agent, the retarder component adopts protein gypsum retarder, and the waterproofing agent component adopts silicone waterproofing agent, such as silicone oil waterproofing agent; The foaming agent component adopts silicone defoamer; the fiber component adopts alkali-resistant glass fiber with a length of 2-5 cm. The weight percent of each component is:

[0022]

[0023] Weigh the required phosphogypsum components, sand components, cement components, water reducer components, retarder components, waterproofing agent components, defoamer components and fibers according to the weight percentage of the above components ...

Embodiment 3

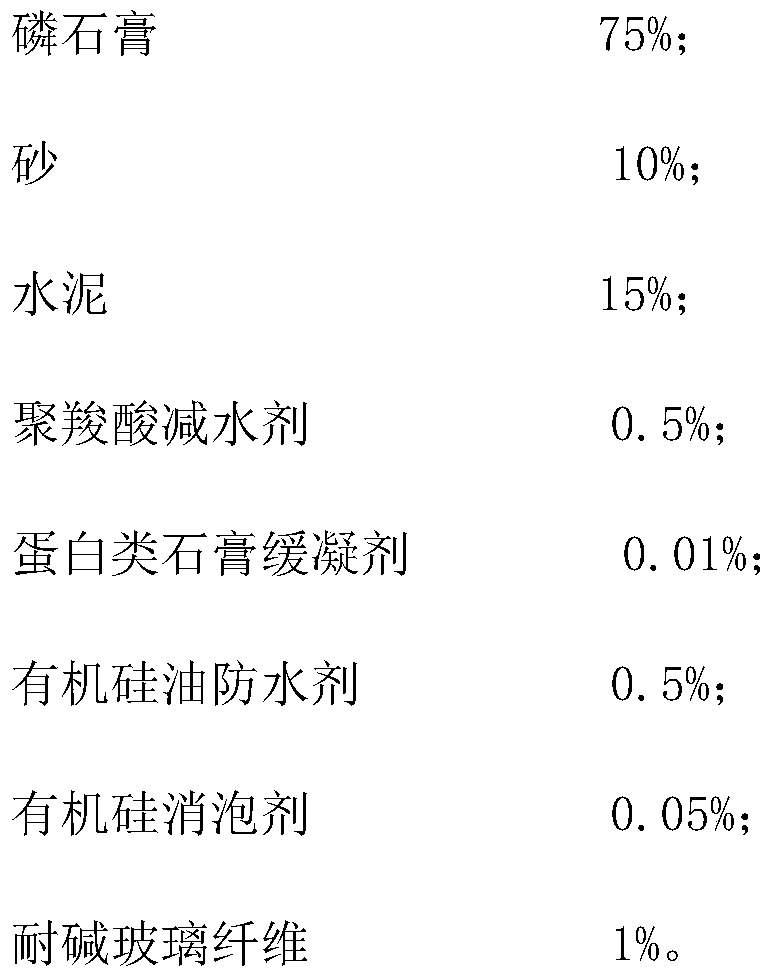

[0026] The phosphogypsum-based fabricated exterior wallboard provided in this embodiment includes phosphogypsum components, sand components, cement components, water reducing agent components, retarder components, waterproofing agent components, defoamer components and fiber component; here, the water reducing agent component uses polycarboxylate water reducing agent, the retarder component adopts protein gypsum retarder, and the waterproofing agent component adopts silicone waterproofing agent, such as silicone oil waterproofing agent; The foaming agent component adopts silicone defoamer; the fiber component adopts alkali-resistant glass fiber with a length of 2-5 cm. The weight percent of each component is:

[0027]

[0028] Weigh the required phosphogypsum components, sand components, cement components, water reducing agent components, retarder components, waterproofing agent components, defoaming agent components, fiber Mix the components to obtain mixed ash. The water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com