Direct methanol fuel cell capable of improving utilization rates of catalysts and preparation method thereof

A methanol fuel cell, utilization rate technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as catalyst inoperability, proton inability to transfer, battery performance degradation, etc., and achieve the effect of high catalyst utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

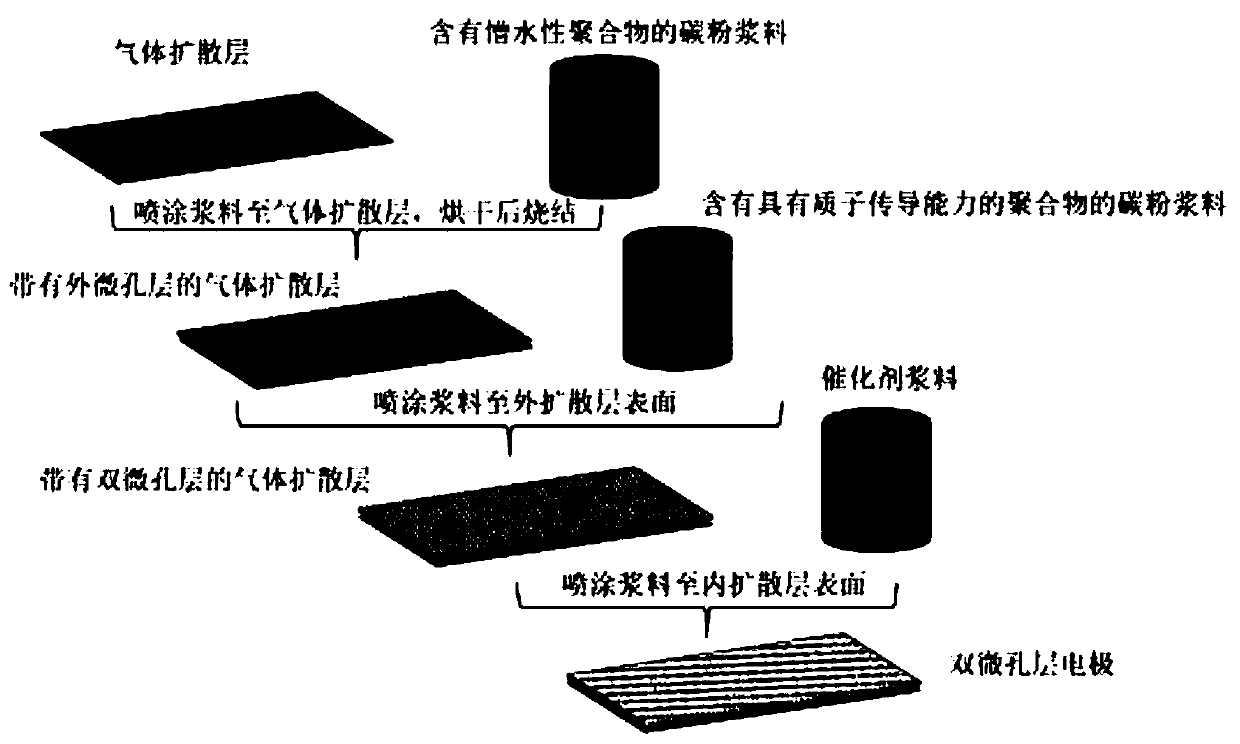

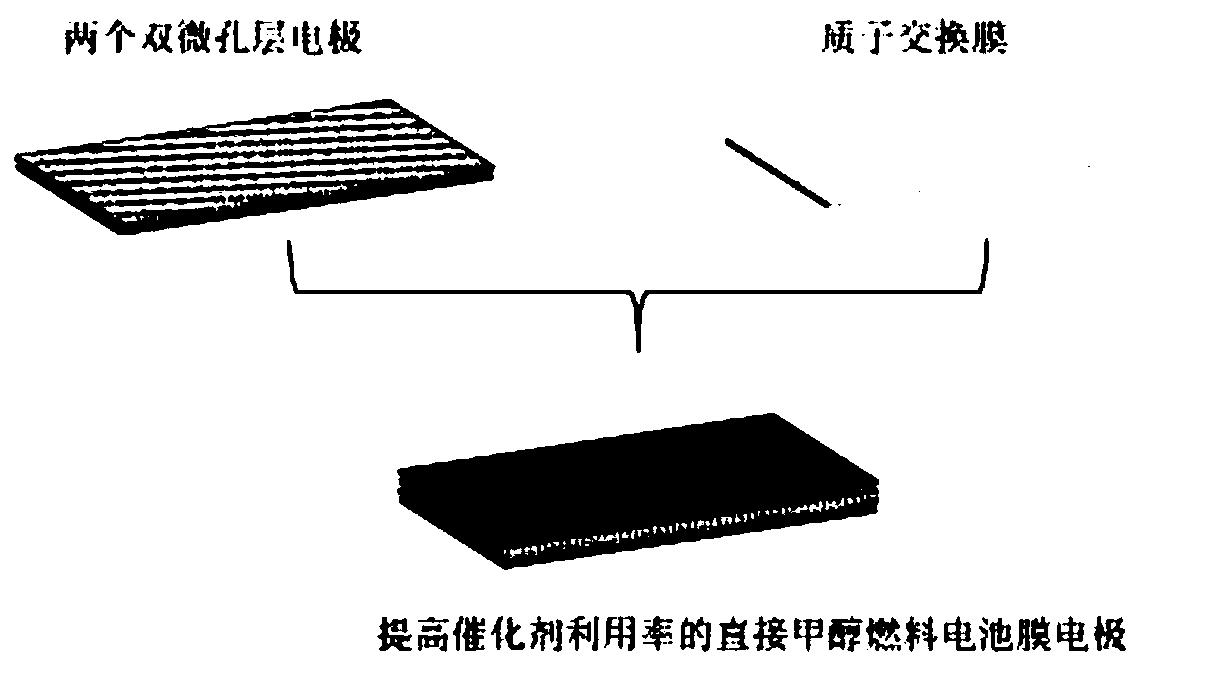

[0059] press figure 2 The shown process and process are used to prepare direct methanol fuel cell electrodes and membrane electrodes with improved catalyst utilization, and conduct discharge tests. The main steps are as follows:

[0060] (1) Preparation of electrodes

[0061] A carbon paper containing polytetrafluoroethylene (PTFE) is used as a diffusion layer, and a microporous layer 2 containing PTFE is coated on the hydrophobic diffusion layer, wherein the content of PTFE is 15 wt.%. The outer microporous layer is coated with a microporous layer 3 containing Nafion, in which the Nafion content is 30 wt.%. Prepare the catalyst slurry in an appropriate ratio and use isopropanol as the solvent. Pt Ru / C is used as a catalyst on the anode side, and Pt / C is used as a catalyst on the cathode side. The catalyst slurry is sprayed on the microporous layer 3 containing Nafion to form a catalyst layer.

[0062] (2) Treatment of proton exchange membrane

[0063] Place the membrane in 5wt.% H...

Embodiment 2

[0069] The direct methanol fuel cell membrane electrode of the catalyst utilization rate of the present invention is tested under the conditions of high concentration of methanol and dry oxygen. First, the double microporous layer electrode was prepared according to the same procedure as in Example 1.

[0070] The obtained membrane electrode assembly and the sealing gas cushion were assembled in a single cell for testing. The test conditions were as follows: battery operating temperature 60℃, normal pressure, anode fuel 2M methanol (flow rate 3ml min -1 ), the cathode inlet is dry oxygen (flow rate is 199ml min -1 ). Limit current density up to 500.21mA cm -2 , The maximum power density reaches 76.29mW cm -2 Compared with Comparative Example 2, Example 2 is increased by 41.01%.

Embodiment 3

[0072] The direct methanol fuel cell membrane electrode of the catalyst utilization rate of the present invention is tested under the conditions of low concentration of methanol and humidified oxygen. First, the double microporous layer electrode was prepared according to the same procedure as in Example 1.

[0073] The obtained membrane electrode assembly and the sealing gas cushion were assembled in a single cell for testing. The test conditions were as follows: the battery operating temperature was 60℃, normal pressure, and the anode fuel was 0.5M methanol (flow rate is 3ml min -1 ), the cathode intake is humidified oxygen (relative humidity is 60%, flow rate is 199ml min -1 ). Limit current density up to 135.05mA cm -2 , The maximum power density reaches 29.12mW cm -2 Compared with Comparative Example 3, Example 3 is improved by 97.38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com