Charging contact structure and preparation method thereof

A charging contact and electrolytic metal technology, which is applied to contact parts, electrical components, printed circuits, etc., can solve the problems that the coating cannot be charged, the coating is electrolyzed, and the static test of artificial sweat cannot pass the salt spray test, etc., so as to improve the flatness and smoothness, solve high temperature demagnetization, and facilitate SMT to the effect of printed circuit board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In the second aspect, the embodiment of the present invention provides a method for preparing the charging contact structure described in the first aspect of the embodiment of the present invention, including: selecting the magnet substrate with specific specifications; performing electroplating on the surface of the magnet substrate, Forming a coating layer; performing hole sealing treatment on the surface of the coating layer to obtain a magnet base material with a coating layer; performing magnetization treatment on the magnet base material with a coating layer to obtain a charging contact structure.

[0052] In a further embodiment, the preparation method of the charging contact structure further includes: SMT the magnet substrate with the coating into the printed circuit board, and then perform magnetization treatment on the magnet substrate with the coating, Get the charging contact structure.

[0053] In this embodiment, the sealing treatment refers to sealing th...

Embodiment 1

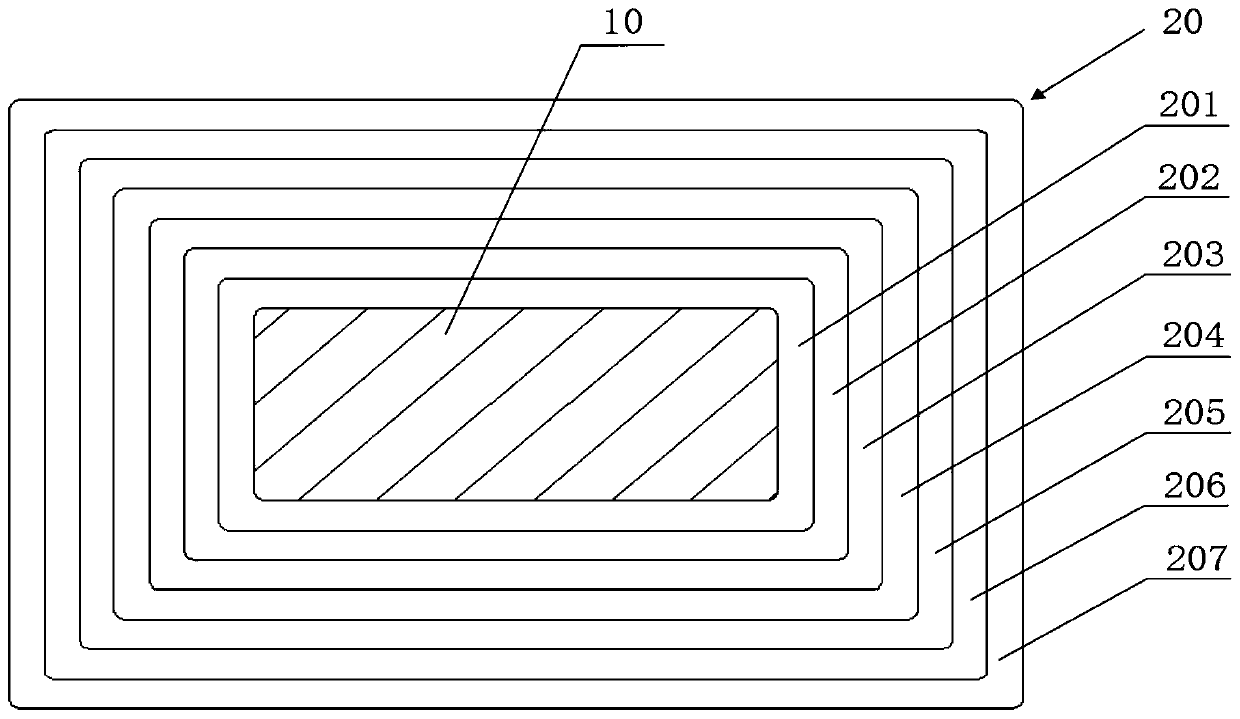

[0056] figure 1 It is a schematic diagram of the coating on NdFeB in Example 1 of the present invention. A charging contact structure, comprising: NdFeB 10, the surface of NdFeB 10 is covered with a coating 20; the coating 20 is in turn from the inside to the outside of a pyro copper coating 201, an acid copper layer 202, a CuSnZn coating 203, a Pd coating 204, The first Au plating layer 205 , the RhRu alloy plating layer 206 and the second Au plating layer 207 . The thickness of the burnt copper plating layer 201 is 8μ-10μ, the thickness of the acid copper layer 202 is 18μ-20μ, the thickness of the CuSnZn plating layer 203 is 2μ-4.5μ, the thickness of the Pd plating layer 204 is 0.6μ-0.75μ, the first Au plating layer 205 The thickness of the RhRu alloy plating layer 206 is 0.75μ-1μ, the thickness of the second Au plating layer 207 is 0.125μ-0.25μ, and the second Au plating layer 207 is the plating layer after sealing treatment.

[0057] A method for preparing a charging con...

Embodiment 2

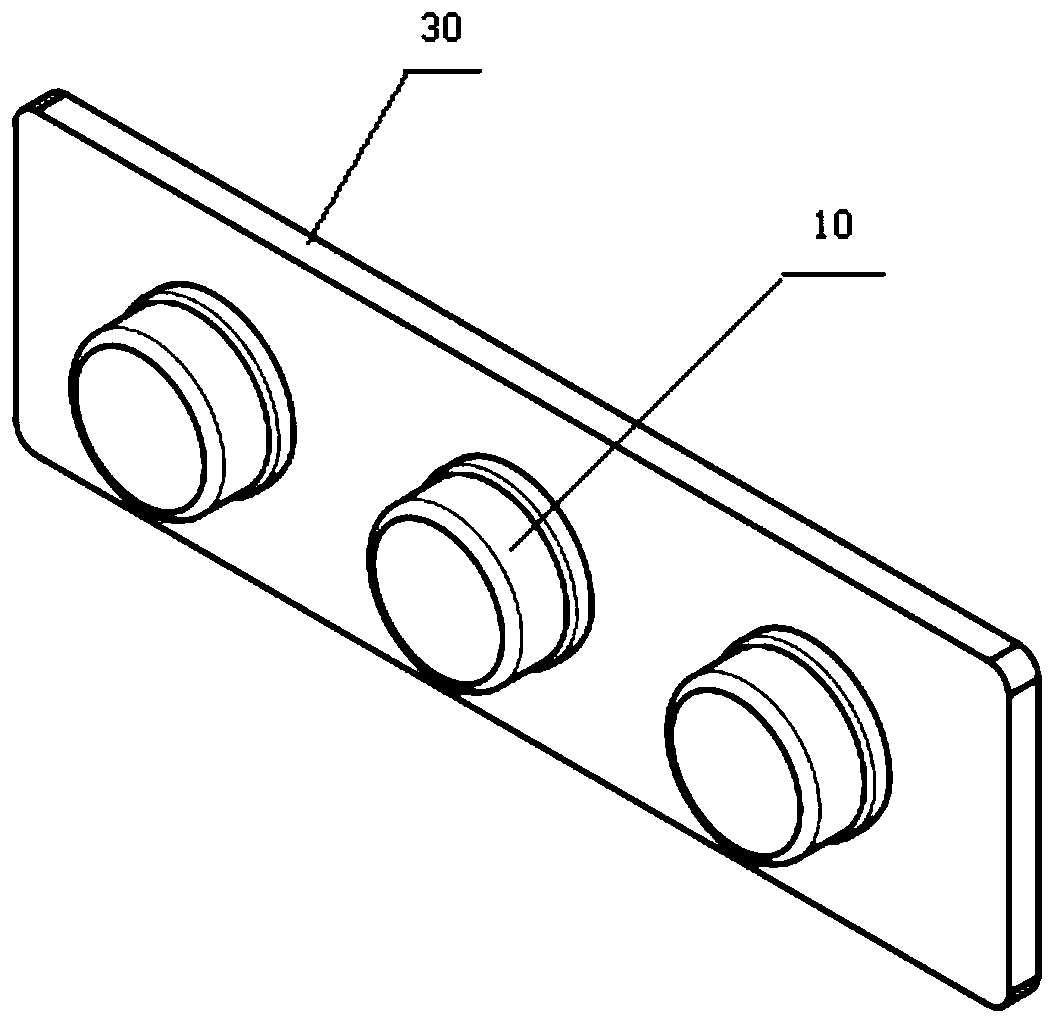

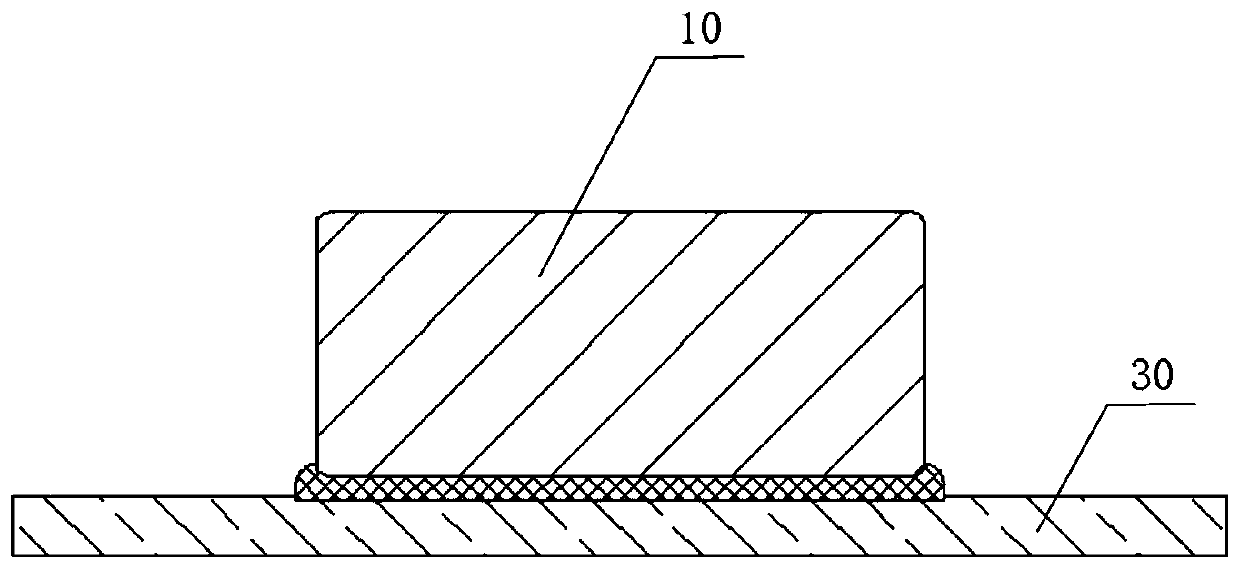

[0073] figure 2 It is a schematic diagram of the charging contact structure in Embodiment 2 of the present invention; image 3 It is a cross-sectional view of the charging contact structure in Embodiment 2 of the present invention. A charging contact structure, comprising: NdFeB 10 and a printed circuit board 30, the NdFeB 10 is connected to the printed circuit board 30 by surface mounting; the surface of the NdFeB 10 is covered with a coating 20; the coating 20 is from the inside to the The outer layers are pyro-copper coating 201 , acid copper coating 202 , CuSnZn coating 203 , Pd coating 204 , first Au coating 205 , RhRu alloy coating 206 and second Au coating 207 . The thickness of the burnt copper plating layer 201 is 8μ-10μ, the thickness of the acid copper layer 202 is 18μ-20μ, the thickness of the CuSnZn plating layer 203 is 2μ-4.5μ, the thickness of the Pd plating layer 204 is 0.6μ-0.75μ, the first Au plating layer 205 The thickness of the RhRu alloy plating layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com