An alkaline all-position co 2 Gas shielded flux cored wire

A flux-cored welding wire, all-position technology, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of no strength results, etc., and achieve the effects of small spatter, improved efficiency, and good weld bead formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

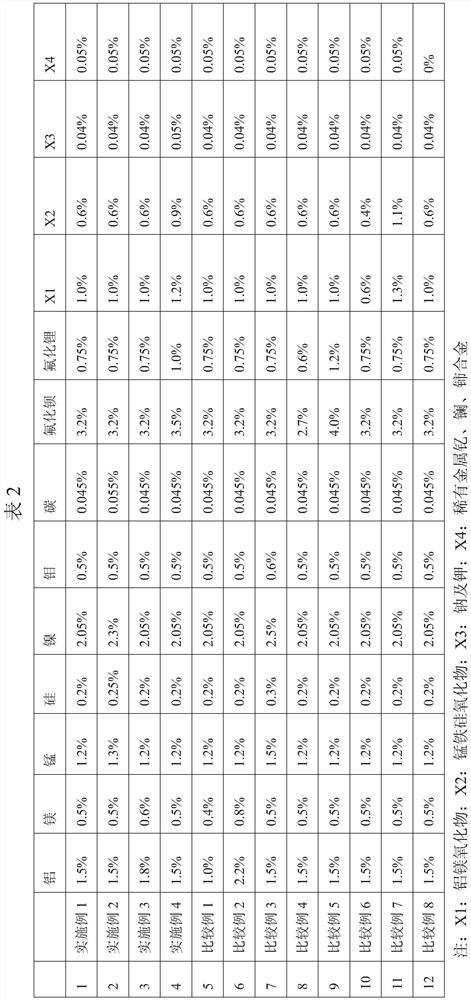

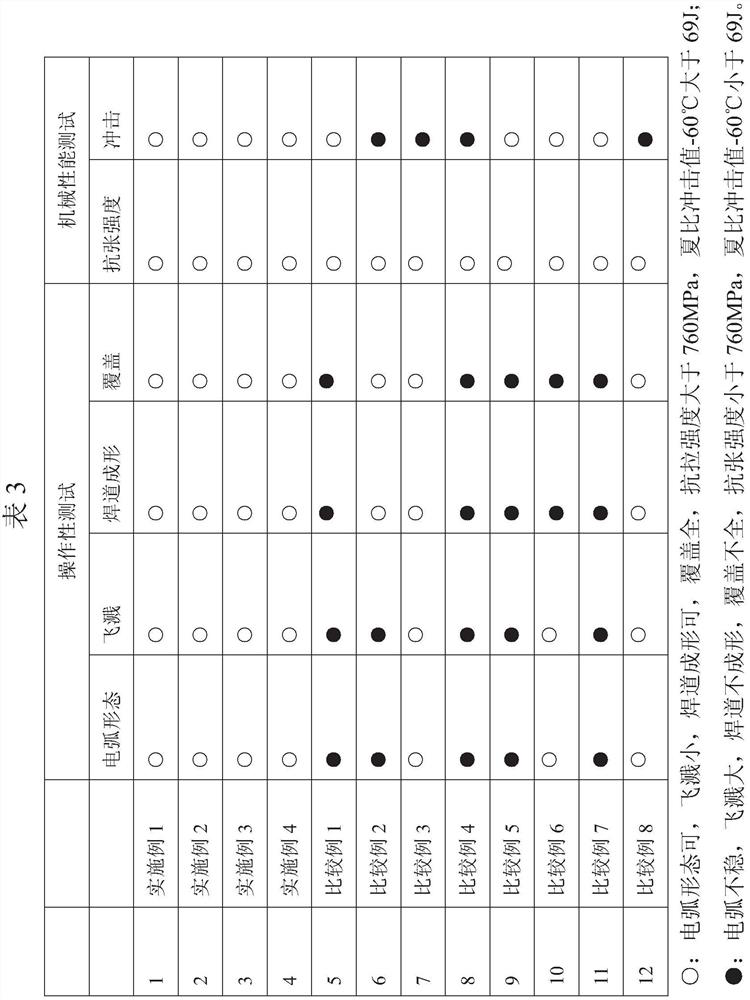

[0029] The technical solutions of the present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these examples.

[0030] The present invention is composed of a steel strip and a drug core, and the drug core is wrapped in the steel strip, and the steel strip components (% by weight) are shown in Table 1.

[0031] Table 1

[0032] C Si mn Al 0.010-0.030 0.01-0.03 0.10-0.30 0.005~0.035 P S Fe 0.005-0.010 0.005-0.010 margin

[0033]The weight percentages of the components in the steel strip and the flux core are as follows: aluminum 1.2%-2.0%, magnesium 0.45%-0.7%, manganese 1.05%-1.4%, silicon 0.18%-0.28%, nickel 1.95%-2.40%, Molybdenum 0.45%-0.55%, carbon 0.035%-0.058%, aluminum magnesium oxide 0.7%-1.3%, manganese iron silicon oxide 0.5%-1%, barium fluoride 2.8%-3.8%, lithium fluoride 0.65%- 1.05%, sodium and potassium less than 0.065%, rare metal yttrium, lant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com