High-alkali coal pretreatment system and high-alkali coal pretreatment method using electrodynamic sodium removal

A high-alkali coal and electric power technology, applied in the field of high-alkali coal pretreatment system, can solve the problems of reducing ash melting point, reducing boiler efficiency, pipe bursting, etc., to improve grade and utilization efficiency, enhance removal effect, and ensure moisture. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

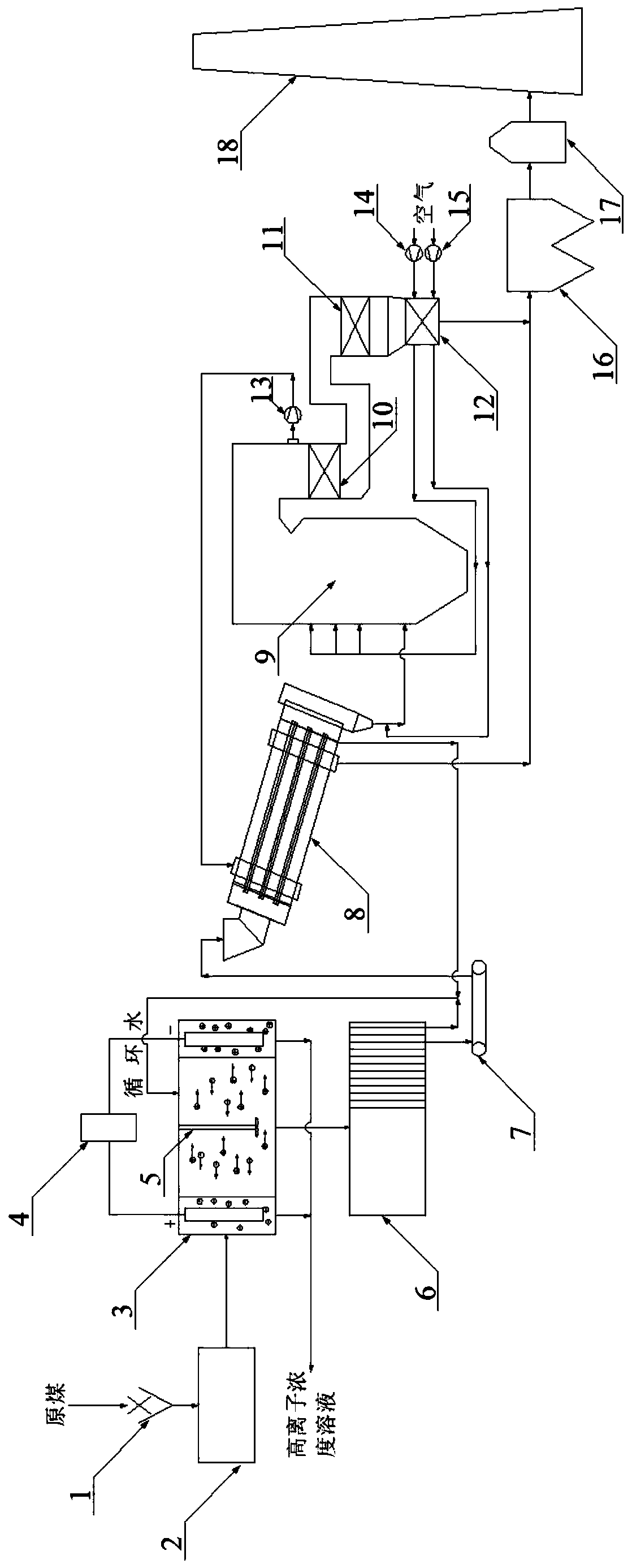

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

[0032] see figure 1 , a high-alkali coal pretreatment system for electrodynamic desodiumization provided by the present invention, including a crusher 1, a coal mill 2, an electrolytic cell 3, a power distribution cabinet 4, a stirring device 5, a filter press 6, and a scraper conveyor Machine 7, drum dryer 8, furnace 9, economizer 10, SCR denitrification device 11, air preheater 12, high temperature induced draft fan 13, primary fan 15, secondary fan 14, dust collector 16, desulfurization device 17 and chimney 18.

[0033]After raw coal enters the crusher 1, it passes through the coal mill 2 to pulverize, and then enters the mixing chamber of the electrolytic cell 3 to form a uniform coal-water slurry under the action of the stirring device 5. At the same time, DC voltage is connected between the cathode and anode electrodes, and the water The cations such as sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com