Preparation method of iron-based amorphous coating

An iron-based amorphous and coating technology, which is applied in coatings and metal material coating processes, can solve problems such as complex processes, cumbersome processes, and slow application processes, and achieve accurate technical parameters, improve coating quality, and enhance The Effect of Amorphous Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

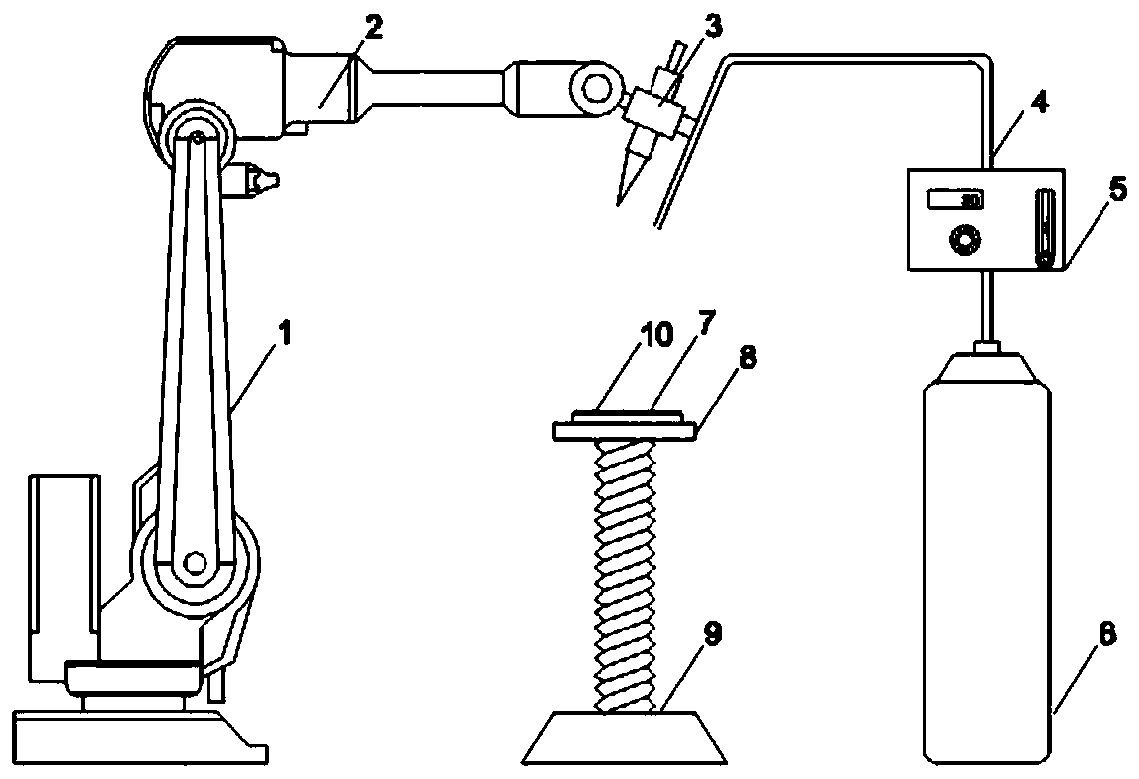

[0050] figure 1 As shown, it is the state diagram of laser cladding welding on the surface of stainless steel plate. The position and connection relationship of each part must be correct and the installation should be firm.

[0051] The laser welding machine is vertical, the middle part of the laser welding machine is the support arm 1, the upper right part of the support arm 1 is the working arm 2, and the right end of the working arm 2 is equipped with a laser cladding welding torch 3, an argon gas pipe 4, an argon The gas pipe 4 is connected to the argon gas bottle 6, and a powder feeder 5 is arranged between the argon gas pipe and the argon gas bottle; The upper part is a stainless steel plate 7, and the upper part of the stainless steel plate 7 is an amorphous coating 10.

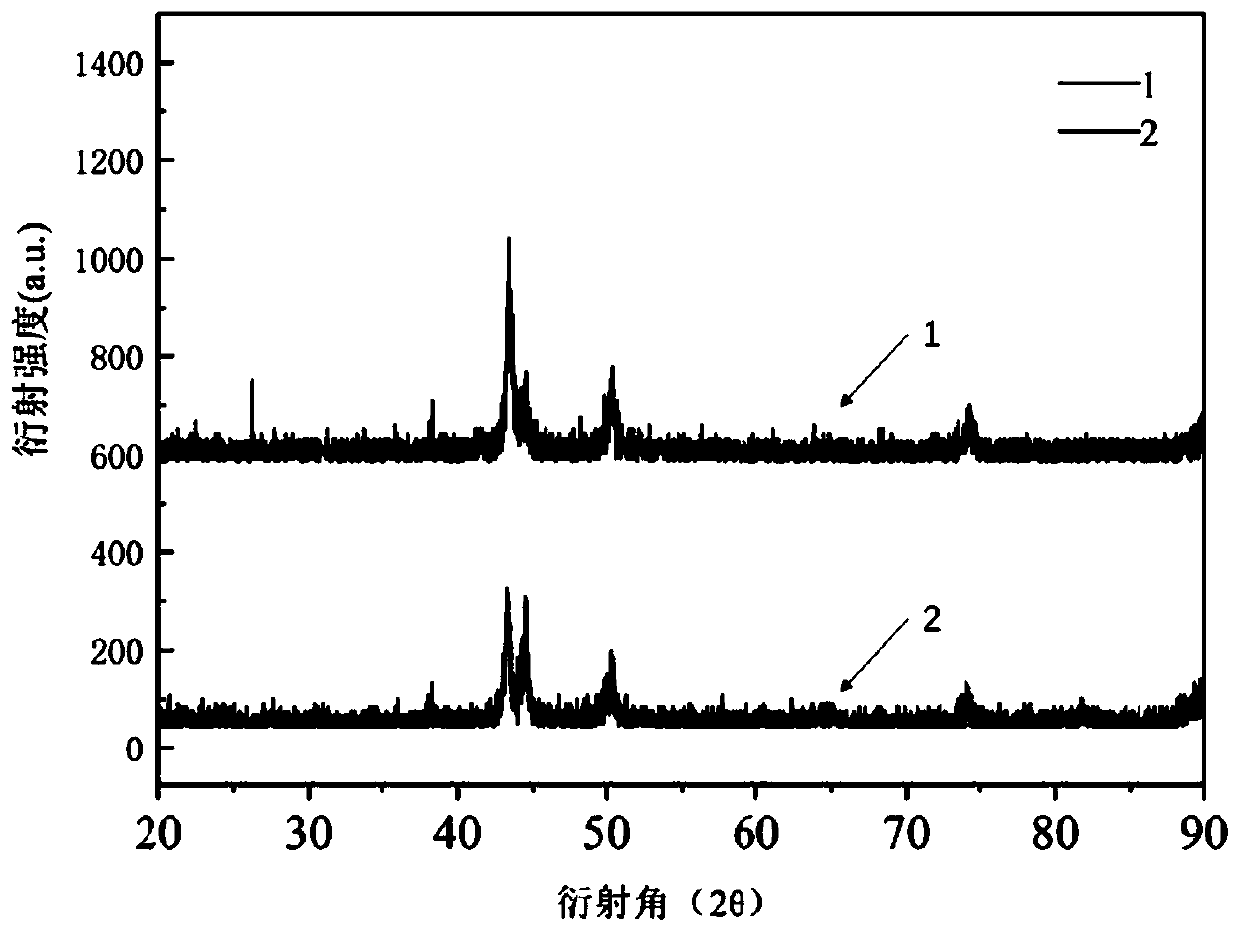

[0052] figure 2 As shown, it is the XRD pattern of the iron-based amorphous coating. Curve 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com