Composite pencil lead and preparation method thereof

A composite material and pen core technology, applied in the field of pen core manufacturing, can solve problems such as fast consumption, blurred diffusion, and small binding force, and achieve the effects of long storage time, good stability, and high lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

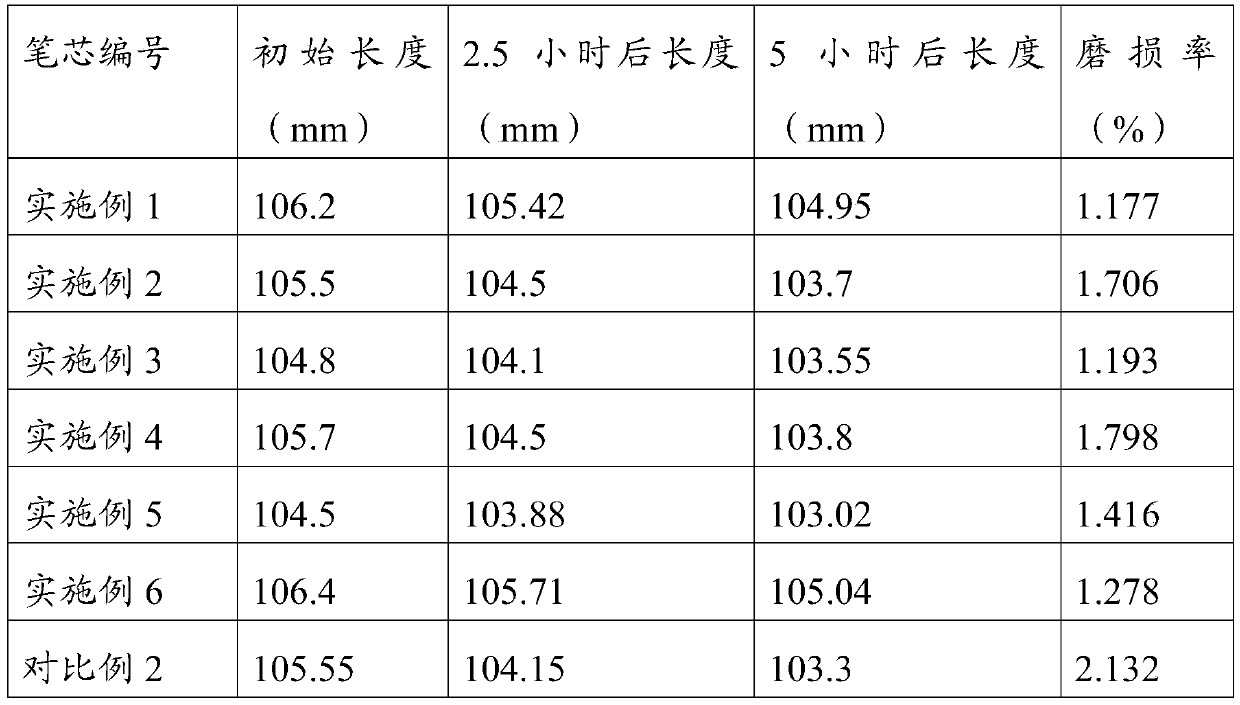

Examples

Embodiment 1

[0031] A composite material pen core, its raw materials include 76 parts of graphite powder, 17 parts of bisphenol A type unsaturated polyester resin, 3 parts of asphalt, 0.1 part of bismuth powder and 0.9 part of indium powder in parts by mass.

[0032] The present invention also provides a preparation method for the above-mentioned composite material pen core, comprising the following steps:

[0033] Step 1: First mix the raw materials evenly according to the proportion, preheat for 3 hours under vacuum conditions, the preheating temperature is 150°C, and then calcine under the protection of carbon at 310°C;

[0034] Step 2: The calcined material is injection molded, and then annealed at 115° C. for 2.5 hours to obtain a rough composite material pen core.

Embodiment 2

[0036] A composite material pen core, its raw materials include 67 parts of graphite powder, 14 parts of bisphenol A type unsaturated polyester resin, 8 parts of pitch, 3 parts of bismuth powder, 0.5 part of indium powder, 0.1 part of gallium powder, 0.1 part of Copper oxide powder.

[0037] The raw materials include 80 parts of graphite powder, 12 parts of bisphenol A unsaturated polyester resin, 6 parts of pitch, 1.2 parts of bismuth powder, 0.8 parts of indium powder, 0.9 parts of gallium powder, 0.3 parts of copper oxide powder, 0.3 parts of Methoxy polyethylene glycol, 0.2 parts of carbon black.

[0038] The present invention also provides a preparation method for the above-mentioned composite material pen core, comprising the following steps:

[0039] Step 1: First mix the raw materials evenly according to the proportion, preheat for 6 hours under vacuum conditions, the preheating temperature is 200°C, and then calcine under the protection of carbon at 340°C;

[0040] ...

Embodiment 3

[0042] A composite material pen core, its raw materials include 90 parts of graphite powder, 12 parts of bisphenol A type unsaturated polyester resin, 5 parts of pitch, 0.7 part of bismuth powder, 1 part of indium powder, 0.5 part of methoxy poly ethylene glycol.

[0043] The present invention also provides a preparation method for the above-mentioned composite material pen core, comprising the following steps:

[0044] Step 1: First mix the raw materials evenly according to the proportion, preheat for 3 hours under vacuum conditions, the preheating temperature is 280°C, and then calcine under the protection of carbon at 330°C;

[0045] Step 2: The calcined material is injection molded, and then annealed at 110° C. for 3 hours to obtain a rough composite material pen core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com