A Microscale Special-shaped Charge Method Based on Electrostatic Template

A micro-scale, powder-charging technology, applied in the field of micro-charges, can solve problems such as difficulty in realizing irregular-shaped powder charges, difficulty in ensuring charge consistency, and unreliable charge density, and achieves easy construction, high filling efficiency, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

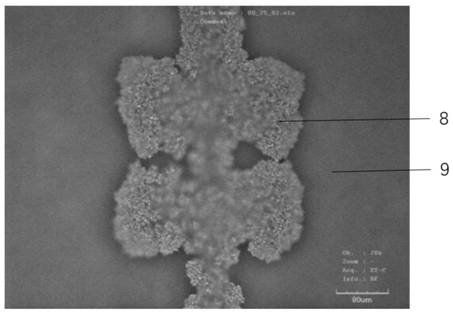

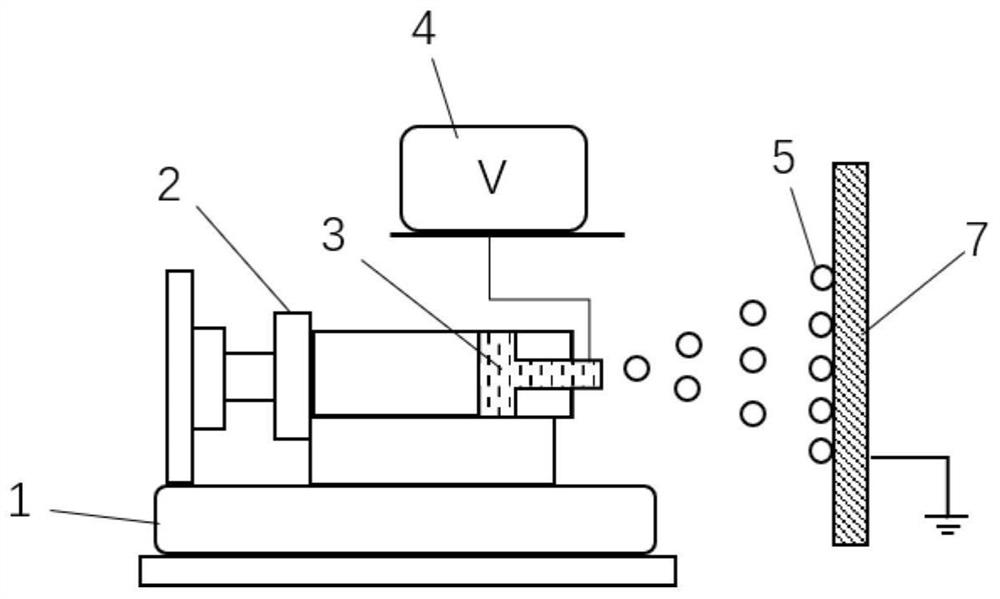

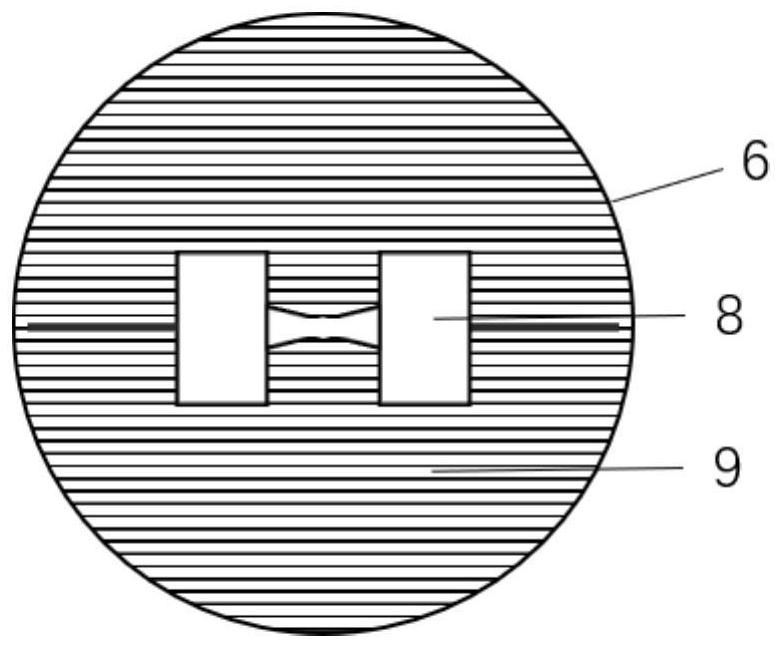

[0045] combine figure 1 , 2 , 4, an electrostatic spraying device comprising a micro-injection pump 1, a syringe 2, an electrostatic spray precursor liquid 3, a high-voltage power supply 4, an electrostatic spray product 5, a special-shaped charge template 6, and a conductive substrate for the flow rate control of the precursor liquid for electrostatic spraying 7, wherein the special-shaped charge template is divided into an electric field conducting part 8 and an electric field insulating part 9

[0046] The micro-scale special-shaped charge method based on the electrostatic template can be completed by the following steps:

[0047] Weigh 15mg of nitrocellulose and add 4ml of ethanol:ether=3:1 (volume ratio) solvent, place on a magnetic stirrer and stir at 600rpm for 1h until the nitrocellulose is completely dissolved to obtain a nitrocellulose solution.

[0048] Weigh 107.45mg of nano-Al powder and 477.55g of nano-copper oxide powder, add them to the prepared nitrocellulose ...

Embodiment 2

[0051] combine figure 1 , 3 , an electrostatic spraying device, comprising a micro-injection pump 1 for controlling the flow rate of a precursor solution for electrostatic spraying, a syringe 2, an electrostatic spray precursor solution 3, a high-voltage power supply 4, an electrostatic spray product 5, a special-shaped charge template 6, and a conductive substrate 7 , wherein the special-shaped charge template is divided into an electric field conducting part 8 and an electric field insulating part 9

[0052] The micro-scale special-shaped charge method based on the electrostatic template can be completed by the following steps:

[0053] Weigh 15mg of nitrocellulose and add 4ml of ethanol:ether=3:1 (volume ratio) solvent, place on a magnetic stirrer and stir at 600rpm for 1h until the nitrocellulose is completely dissolved to obtain a nitrocellulose solution.

[0054] Weigh 107.45mg of nano-Al powder and 477.55g of nano-copper oxide powder, add them to the prepared nitrocel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com