Multi-component quality control method for callicarpa nudiflora

A quality control method, the technology of naked flower purple pearl, applied in the direction of measuring device, material separation, material analysis, etc., can solve the problems such as the complex composition of naked flower purple pearl traditional Chinese medicine, which is not enough to fully control the quality of naked flower purple pearl medicinal materials, and achieve Good precision and reproducibility, simple operation, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

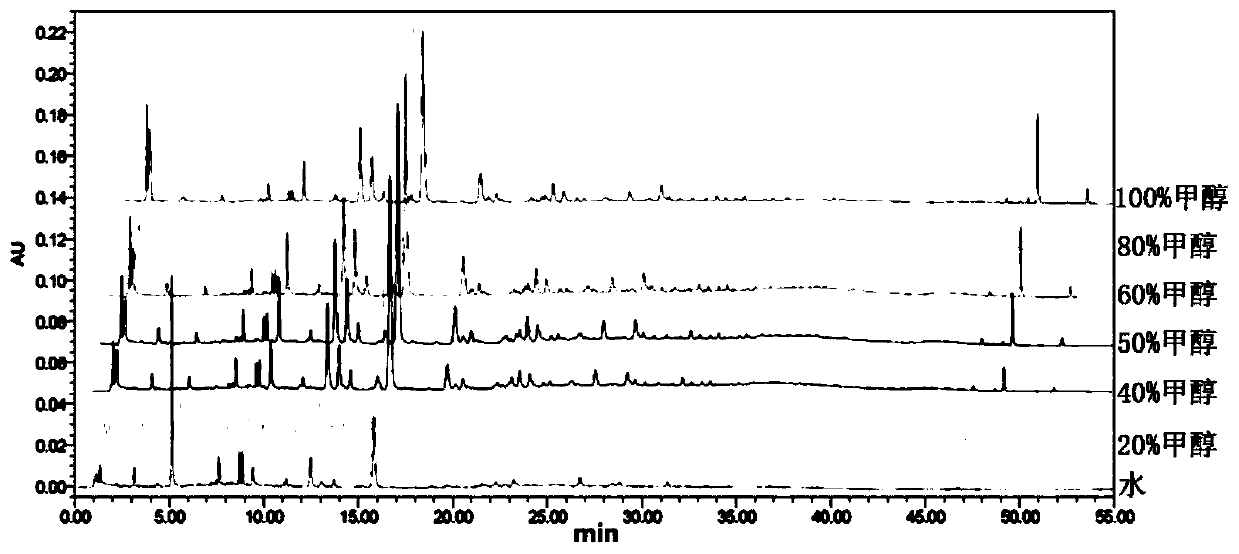

[0032] Take a sample of Auranthus nudiflora and pulverize it, pass through a 40-mesh sieve, accurately weigh 0.5 g of the sample powder, 7 parts in total, place them in conical flasks with stoppers, add pure water, 20% methanol aqueous solution, 40% methanol aqueous solution, 50% methanol water solution, 60% methanol water solution, 80% methanol water solution, 25mL of pure methanol, weighed, ultrasonicated for 45min, allowed to cool to 100%, and the corresponding solvent was used to make up for weight loss, shake well, pass through a 0.22μm microporous membrane, and take the continuation The filtrate was used as the test solution. Using Agilent 1200Infinity high resolution fast liquid chromatography; Agilent Eclipse Plus-C 18 The RRHD column has an outer diameter of 2.1 mm×column length of 150 mm, and a packing diameter of 1.8 μm. The mobile phase is (A) 0.1% aqueous formic acid and (B) acetonitrile, and the gradient elution is as follows:

[0033] time (minutes) ...

Embodiment 2

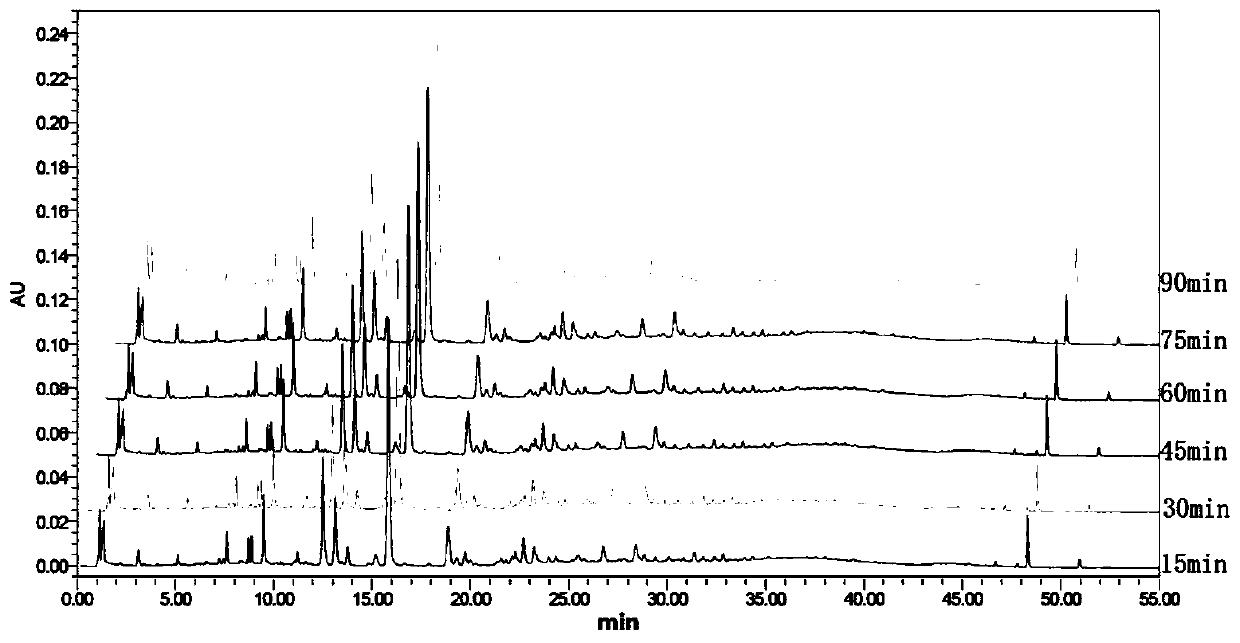

[0037] Take a sample of Nadiflora purple pearl and crush it, pass it through a 40-mesh sieve, accurately weigh 0.5g of the sample powder, a total of 6 parts, place them in a stoppered conical flask, add 25mL of 80% methanol aqueous solution, weigh, and weigh the 6 parts of the sample respectively. Sonicate for 15min, 30min, 45min, 60min, 75min, 90min, let cool, make up for the weight loss with 80% methanol, shake well, pass through a 0.22μm microporous membrane, and take the subsequent filtrate as the test solution. Using Agilent 1200Infinity high resolution fast liquid chromatography; Agilent Eclipse Plus-C 18 The RRHD column has an outer diameter of 2.1 mm×column length of 150 mm, and a packing diameter of 1.8 μm. The mobile phase is (A) 0.1% aqueous formic acid and (B) acetonitrile, and the gradient elution is as follows:

[0038] time (minutes) Mobile phase (v / v%) time (minutes) Mobile phase (v / v%) 0~5min 8%~14%B 30~40min 22%~30%B 5~15min 14~1...

Embodiment 3

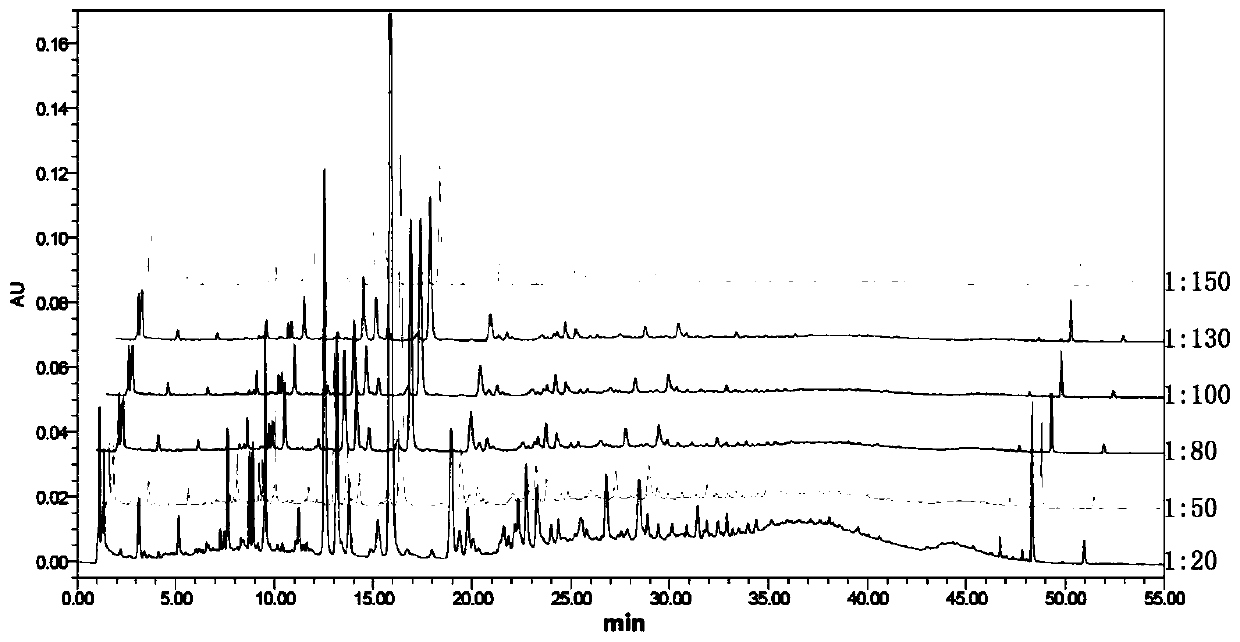

[0042] Take a sample of Auranthus nudiflora and crush it, pass it through a 40-mesh sieve, accurately weigh 0.5 g of the sample powder, a total of 6 parts, place them in conical flasks with stoppers, add 10 mL of 80% methanol aqueous solution, 25 mL, 40 mL, 50 mL, Weigh 65mL and 75mL, sonicate for 45min, let cool, make up for weight loss with 80% methanol, shake well, pass through a 0.22μm microporous membrane, and take the subsequent filtrate as the test solution. Using Agilent 1200Infinity high resolution fast liquid chromatography; Agilent Eclipse Plus-C18 The RRHD column has an outer diameter of 2.1 mm×column length of 150 mm, and a packing diameter of 1.8 μm. The mobile phase is (A) 0.1% aqueous formic acid and (B) acetonitrile, and the gradient elution is as follows:

[0043] time (minutes) Mobile phase (v / v%) time (minutes) Mobile phase (v / v%) 0~5min 8%~14%B 30~40min 22%~30%B 5~15min 14~18%B 40~45min 30%~50%B 20~30min 18%~22%B 45~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com