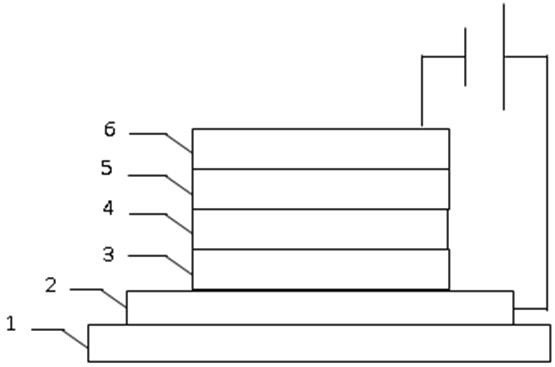

A kind of nanometer material and its preparation method and quantum dot light-emitting diode

A technology of quantum dot luminescence and nanomaterials, which is applied in the field of quantum dot light-emitting devices, can solve the problem of low hole transmission efficiency, achieve the effects of improving hole transmission efficiency, simple preparation method, and improving luminous efficiency and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: The following uses ammonium molybdate, concentrated nitric acid, and ammonium sulfide to prepare nanomaterials as an example for detailed introduction.

[0058] (1) Add 1 g of ammonium molybdate to 20 mL of water, wait for complete dissolution, add 3 mL of concentrated nitric acid, and stir for 30 min. Then transferred to the hydrothermal reactor, at 200 o C for 24 h, followed by cooling and washing (washing twice with water, once with absolute ethanol), at 50 o Drying at C yields MoO 3 nanoparticles;

[0059] (2) The dried MoO 3 Nanoparticles were ultrasonically dispersed in 20 mL of a mixed solution of water and ethanol (the volume ratio of water and ethanol was 2:3), until a homogeneous MoO 3 After the nanoparticle dispersion, 0.1 g of ammonium sulfide was added, and the dispersion was transferred to a hydrothermal reactor, at 200 o C for 24 h, followed by cooling and washing (washing twice with water, once with absolute ethanol), at 50 o Dry at C...

Embodiment 2

[0060] Embodiment 2: The following takes the preparation of nanomaterials by using sodium molybdate, concentrated sulfuric acid and thiourea as an example to introduce in detail.

[0061] (1) Add 1 g of sodium molybdate to 20 mL of water, wait for complete dissolution, add 3 mL of concentrated sulfuric acid, and stir for 30 min. Then transferred to the hydrothermal reactor, at 200 o C for 24 h, followed by cooling and washing (washing twice with water, once with absolute ethanol), at 50 o Drying at C yields MoO 3 nanoparticles;

[0062] (2) The dried MoO 3 Nanoparticles were ultrasonically dispersed in 20 mL of a mixed solution of water and ethanol (the volume ratio of water and ethanol was 2:3), until a homogeneous MoO 3 After the nanoparticle dispersion, 0.1 g of thiourea was added, and the dispersion was transferred to a hydrothermal reactor, at 200 o C for 24 h, followed by cooling and washing (washing twice with water, once with absolute ethanol), at 50 o Dry at C t...

Embodiment 3

[0063] Embodiment 3: The following takes the preparation of nanomaterials by using potassium molybdate, concentrated hydrochloric acid and thioacetamide as an example to introduce in detail.

[0064] (1) Add 1 g of potassium molybdate to 20 mL of water, wait for complete dissolution, add 3 mL of concentrated hydrochloric acid, and stir for 30 min. Then transferred to the hydrothermal reactor, at 200 o C for 24 h, followed by cooling and washing (washing twice with water, once with absolute ethanol), at 50 o Drying at C yields MoO 3 nanoparticles;

[0065] (2) The dried MoO 3 Nanoparticles were ultrasonically dispersed in 20 mL of a mixed solution of water and ethanol (the volume ratio of water and ethanol was 2:3), until a homogeneous MoO 3 After the nanoparticle dispersion, add 0.1 g of thioacetamide, and transfer the dispersion to a hydrothermal reaction kettle, at 200 o C for 24 h, followed by cooling and washing (washing twice with water, once with absolute ethanol), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com