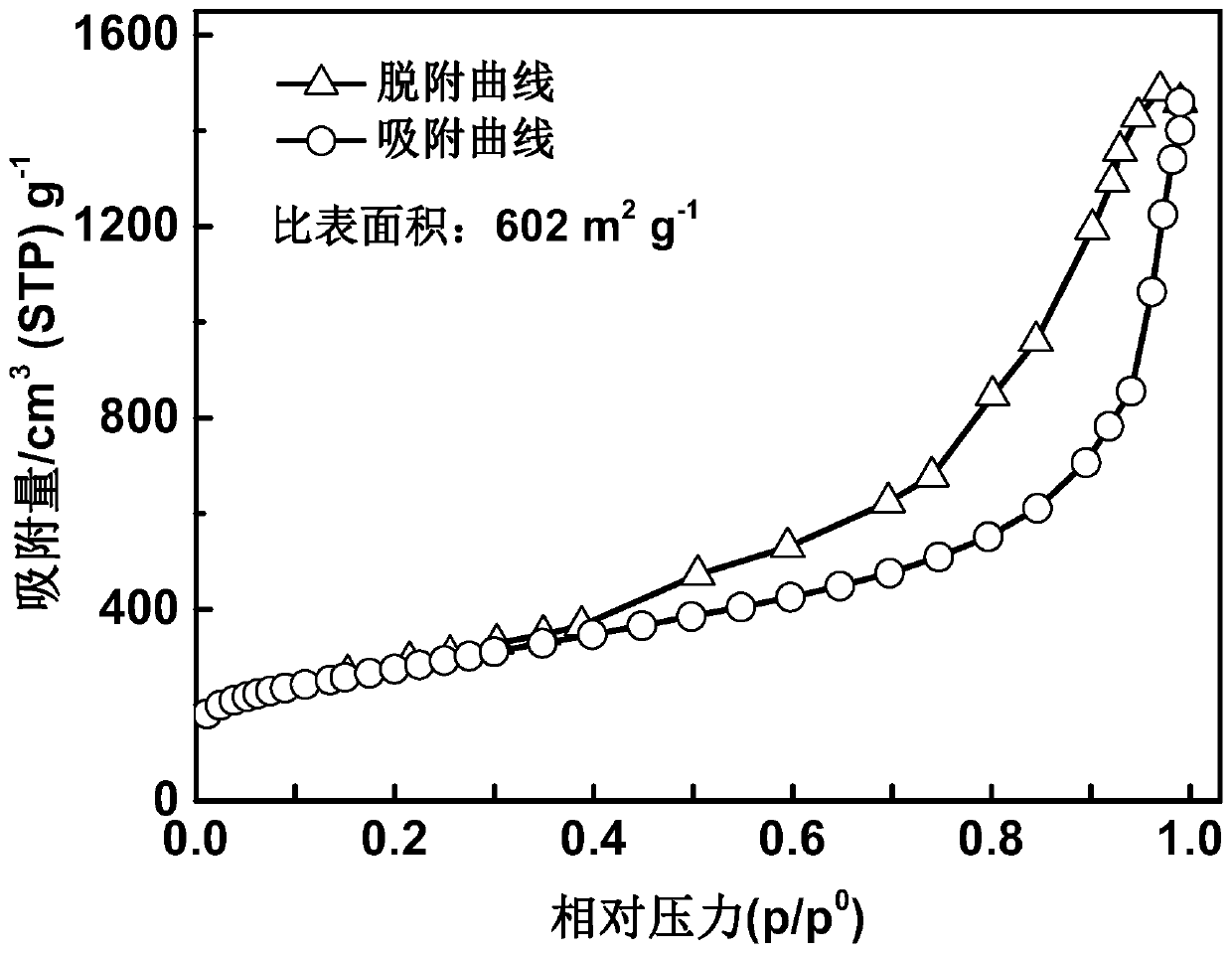

Boron-nitrogen co-doped porous graphene as well as preparation method and application thereof

A porous graphene, co-doping technology, applied in the preparation/separation of ammonia, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as low preparation efficiency, harsh pore-making conditions, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of boron-nitrogen co-doped porous graphene catalyst, comprising the steps of:

[0058] (1) Place the quartz boat with 100 mg of graphene in the heating zone of the tube furnace, heat the steam generator to 150°C, turn on the pure water peristaltic pump, and feed water vapor and argon, the flow rate of water vapor is 0.05 mL / min, the flow rate of argon gas is 50mL / min, heat treatment is carried out by raising the temperature, the heating rate is 20 ℃ / min, the temperature of heat treatment is 800 ℃, and the time of heat treatment is 1 h. During this process, water vapor Accompanied by the Ar atmosphere entering the heating zone of the tube furnace, it reacts with graphene to produce in-plane nanopores. At the same time, water vapor has weak oxidizing properties, and can functionalize the edges of the pores to obtain porous graphene. The porous graphene The pore size is 8.9 nm;

[0059] (2) in NH 3 In a mixed atmosphere with Ar, the porous graphene (...

Embodiment 2

[0071] A preparation method of boron-nitrogen co-doped porous graphene catalyst, comprising the steps of:

[0072] (1) Place the quartz boat with 100 mg of graphene in the heating zone of the tube furnace, heat the steam generator to 150°C, turn on the pure water peristaltic pump, and feed water vapor and argon, the flow rate of water vapor is 0.015 mL / min, the flow rate of argon gas is 50 mL / min, heat treatment is carried out by raising the temperature, the heating rate is 5 ℃ / min, the temperature of heat treatment is 800 ℃, and the time of heat treatment is 1 h. Steam enters the heating zone of the tube furnace with the Ar atmosphere to react with graphene to generate in-plane nanopores. At the same time, water vapor has weak oxidizing properties and can functionalize the edges of the pores to obtain porous graphene. The porous graphene The average pore diameter is 8.1 nm;

[0073] (2) in NH 3 In a mixed atmosphere with Ar, the porous graphene (50 mg) described in step (1)...

Embodiment 3

[0085] A preparation method of boron-nitrogen co-doped porous graphene, comprising the steps of:

[0086] (1) Place the quartz boat with 100 mg of graphene in the heating zone of the tube furnace, heat the steam generator to 150°C, turn on the pure water peristaltic pump, and feed water vapor and argon, the flow rate of water vapor is 0.05 mL / min, the flow rate of argon gas is 50 mL / min, heat treatment is carried out by raising the temperature, the heating rate is 5 ℃ / min, the temperature of heat treatment is 800 ℃, and the time of heat treatment is 1 h. During this process, water vapor Accompanied by the Ar atmosphere entering the heating zone of the tube furnace, it reacts with graphene to produce in-plane nanopores. At the same time, water vapor has weak oxidizing properties, and can functionalize the edges of the pores to obtain porous graphene. The porous graphene The average pore size is 9.3 nm;

[0087] (2) in NH 3 In a mixed atmosphere with Ar, the porous graphene (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com