Nitrogen-doped three-dimensional nano porous carbon/porous graphene composite material and preparation method thereof

A technology of porous graphene and nanoporous carbon, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as low conversion efficiency and reduced graphene electronic conductivity, and achieve wide applicability and high specific surface area , the effect of high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

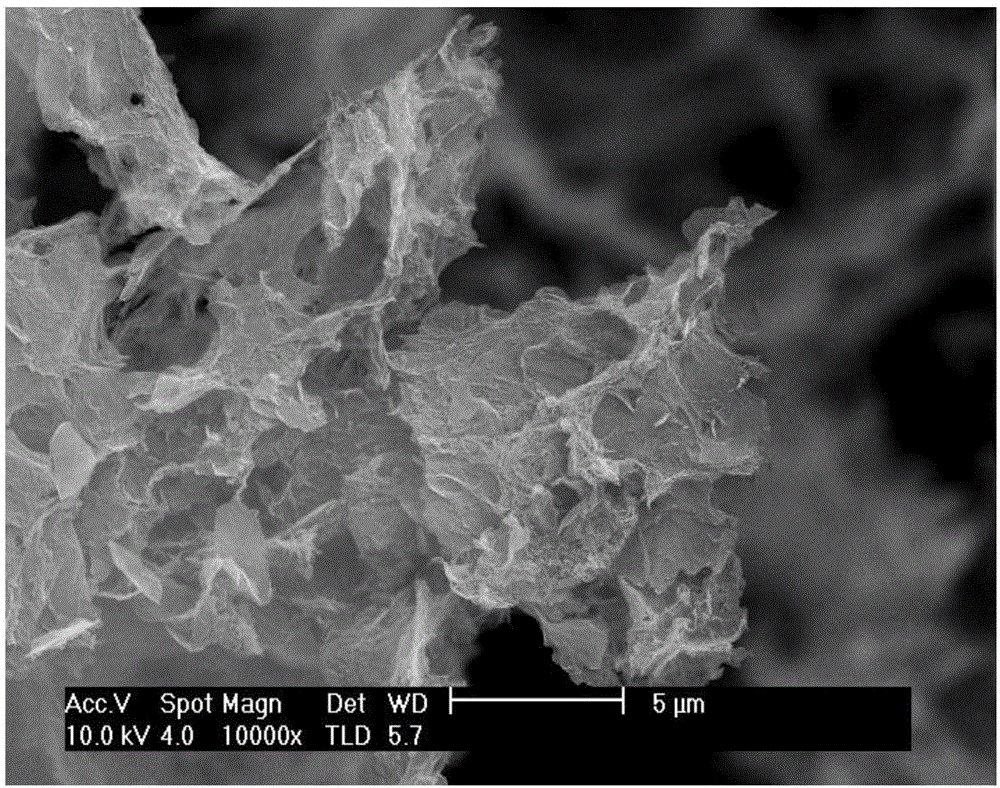

Embodiment 1

[0025] 3.2ml 5mg ml -1 Add 6.4ml of methanol to the GO aqueous solution, then add 12ml of methanol solution containing 0.36g of zinc nitrate hexahydrate and 20ml of methanol solution containing 0.8g of 2-methylimidazole, stir for 3 hours and centrifuge to obtain GO / ZIF gray precipitate; Dissolve in 20ml of ethanol, add 10ul 40% hydrofluoric acid as etchant, mix well, transfer the mixed solution to a 50ml reactor and heat to 180°C for 6h hydrothermal reaction; the obtained ZIF / porous graphene The three-dimensional structure was transferred to a petri dish, washed with ethanol until the pH value was neutral, then frozen at -50°C for 6 hours, and freeze-dried for 12 hours; the dried ZIF / porous graphene three-dimensional structure was transferred to a tube furnace and heated in argon Keep at 800°C for 3 hours under protection, ZIF is carbonized to form porous carbon supported on the surface of graphene sheets in a three-dimensional structure, at the same time, nitrogen doping in Z...

Embodiment 2

[0027] 0.8ml 5mg ml -1 Add 6.4ml methanol to the GO aqueous solution, then add 12ml methanol solution containing 0.1g zinc nitrate hexahydrate and 20ml methanol solution containing 0.5g 2-methylimidazole, stir for 2h and centrifuge to get GO / ZIF gray precipitate; Dissolve in 10ml of ethanol, add 5ul 40% hydrofluoric acid as an etchant, mix well, transfer the mixed solution to a 50ml reactor and heat to 180°C for 3h of hydrothermal reaction; the obtained ZIF / porous graphene The three-dimensional structure was transferred to a petri dish, washed with ethanol until the pH value was neutral, then frozen at -50°C for 6 hours, and then freeze-dried for 6 hours; the dried ZIF / porous graphene three-dimensional structure was transferred to a tube furnace and heated in argon Keep at 500℃ for 1h under protection, ZIF is carbonized to form porous carbon supported on the surface of graphene sheets in a three-dimensional structure, and nitrogen doping in ZIF enters the graphene network duri...

Embodiment 3

[0029] 6.4ml 5mg ml -1 Add 6.4ml of methanol to the GO aqueous solution, then add 12ml of methanol solution containing 0.6g of zinc nitrate hexahydrate and 20ml of methanol solution containing 1g of 2-methylimidazole, stir for 6 hours and centrifuge to obtain GO / ZIF gray precipitate; re-dissolve after fully washing To 30ml of ethanol, add 50ul 40% hydrofluoric acid as an etchant, mix well, transfer the mixed solution to a 50ml reactor and heat to 180°C for 12h of hydrothermal reaction; the obtained ZIF / porous graphene three-dimensional The structure was transferred to a petri dish, washed with ethanol until the pH value was neutral, then frozen at -50°C for 12 hours, and then freeze-dried for 24 hours; the dried ZIF / porous graphene three-dimensional structure was transferred to a tube furnace, under the protection of argon Keep at 1000°C for 6 hours, ZIF is carbonized to form porous carbon supported on the surface of graphene sheets in the three-dimensional structure, and nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com