Liposome, preparation method thereof, liposome assembly and carrier liposome complex

A liposome and liposome technology, which is applied in the field of liposome assemblies and liposome complexes, can solve the problems of low drug utilization, low drug concentration, and lack of selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

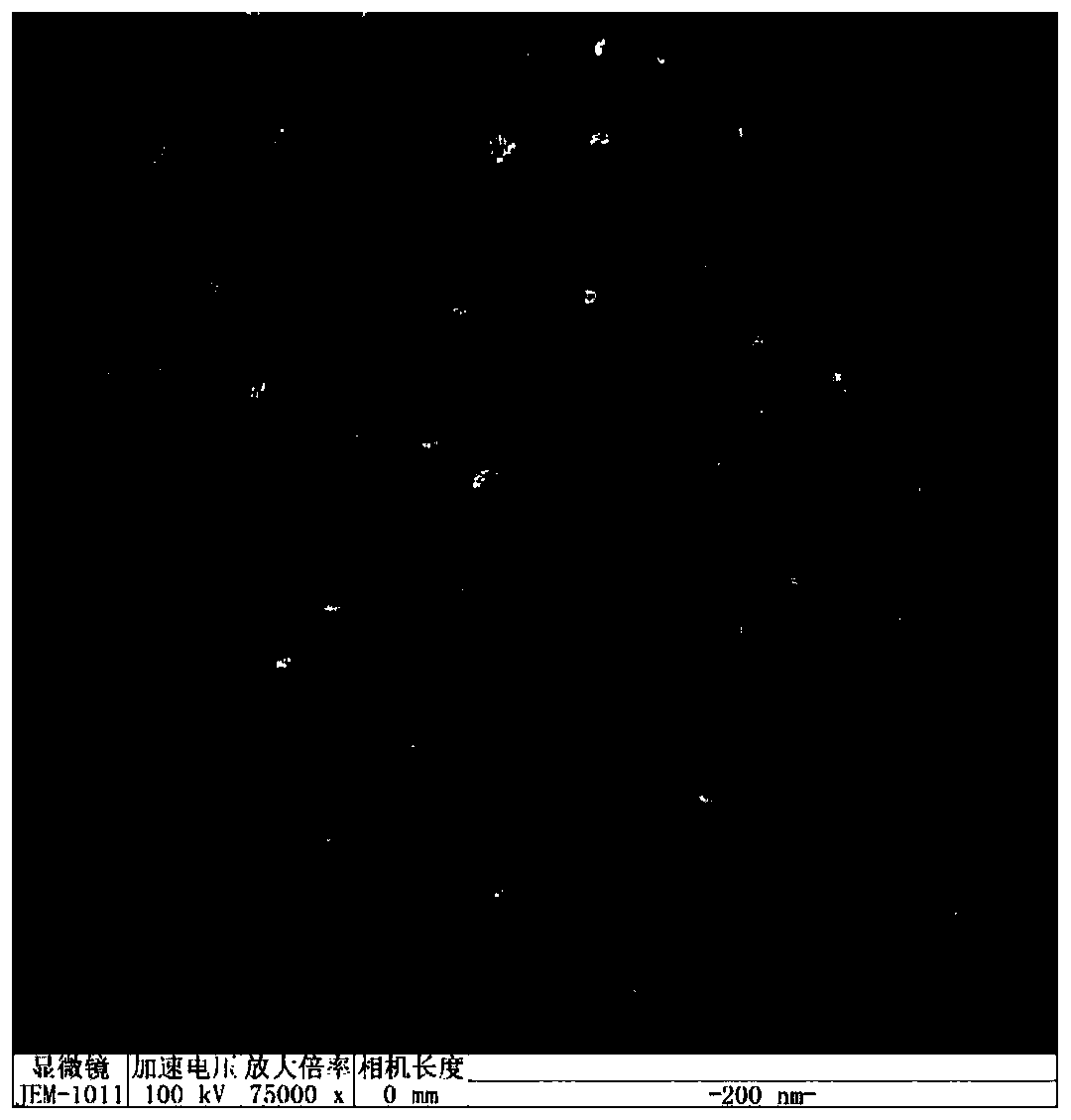

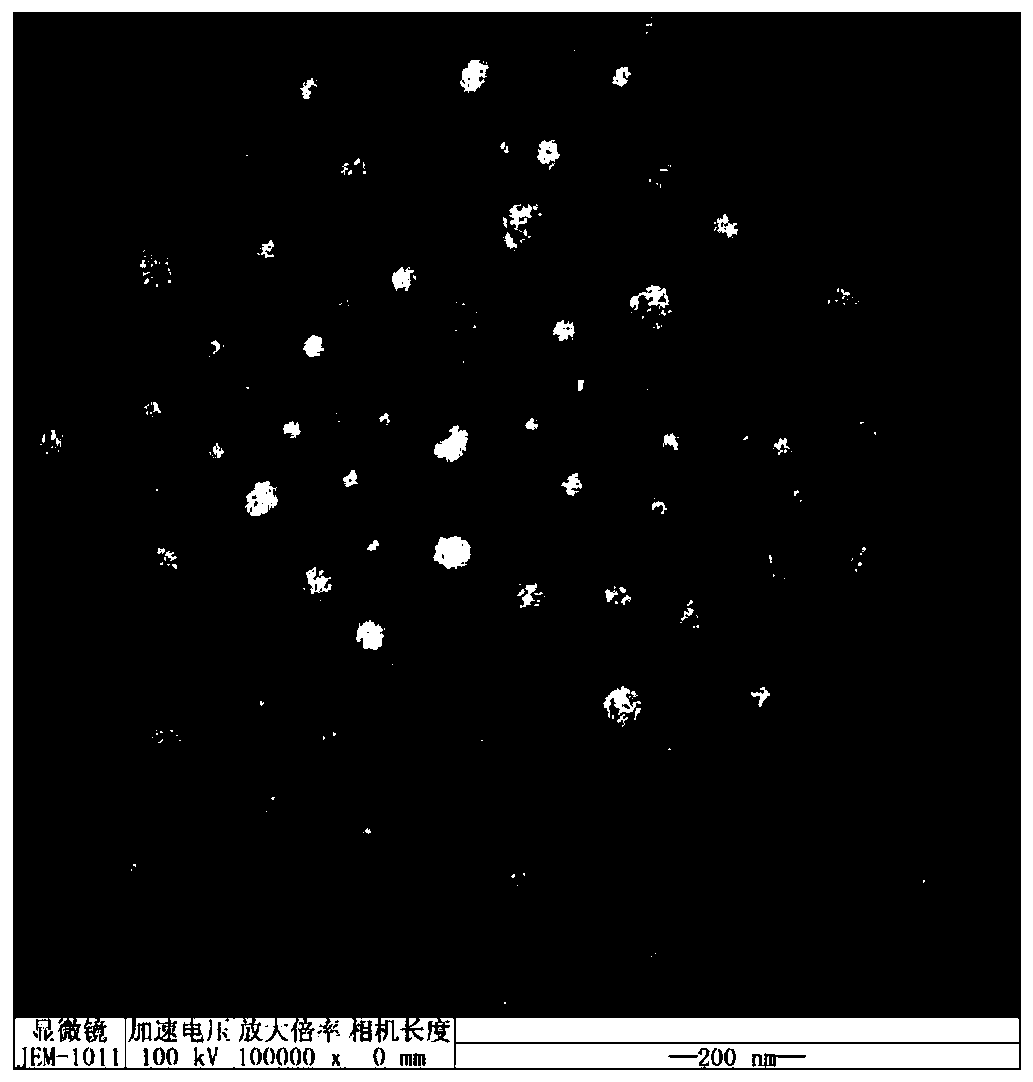

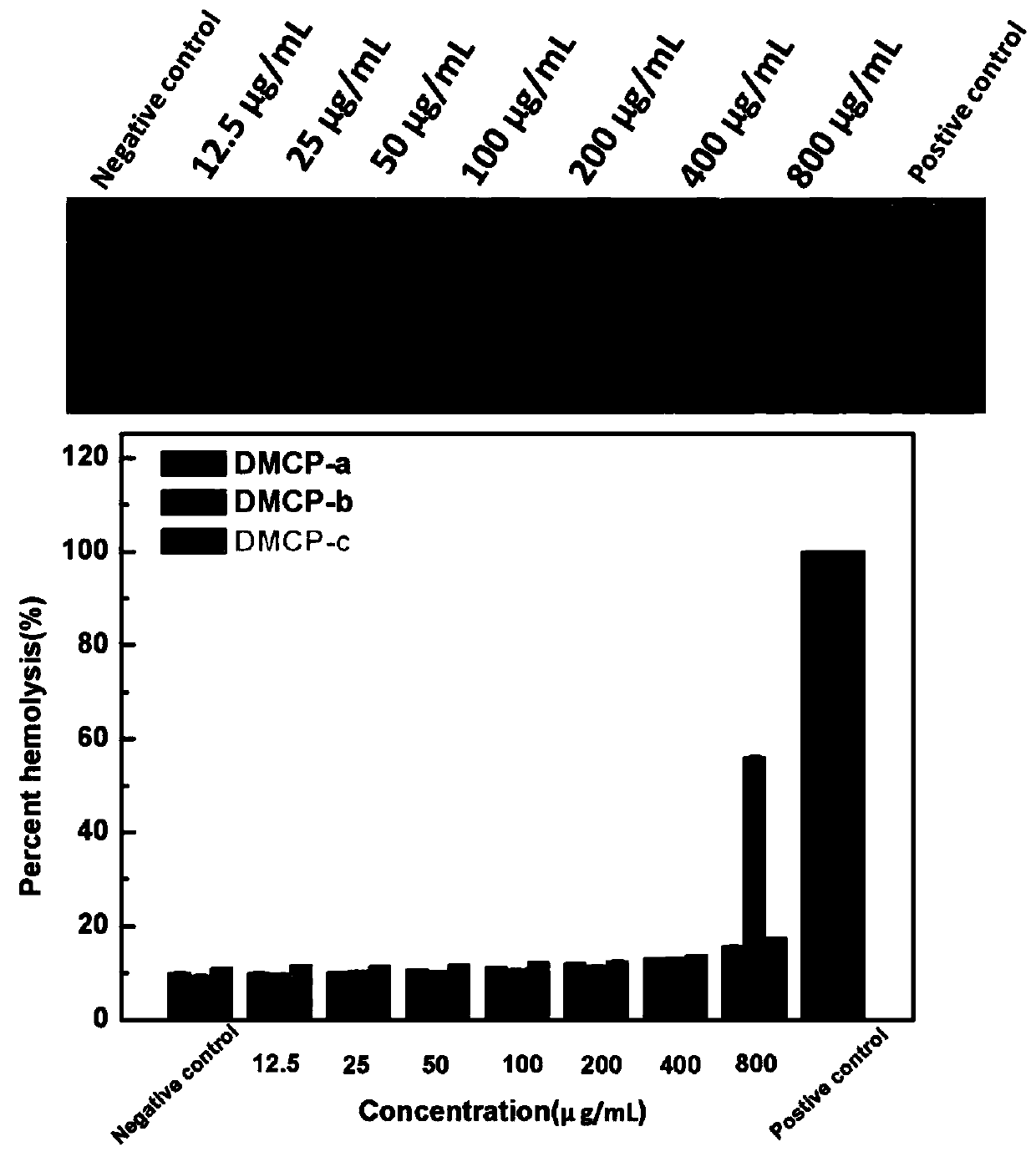

Image

Examples

preparation example Construction

[0124] According to the present invention, the first preparation method of the liposome comprises the following steps:

[0125] a) compound A 1 -COOH, Compound A 2 -COOH is reacted with 1,2-propanediol derivative X-1 to obtain compound Y-1;

[0126] b) reacting the phospholane compound X-2 with the dimethylamine compound X-3 to obtain the compound Y-2;

[0127] c) reacting the compound Y-1 with the compound Y-2 to obtain liposomes represented by formula (I);

[0128] The steps a) and b) have no order limitation;

[0129]

[0130] in,

[0131] A 1 and A 2 Independently selected from hydrocarbyl C x h 2x+y ; x is an integer from 5 to 35, and y is 1, -1, -3, -5, -7, -9 or -11;

[0132] no 1 , n 2 , L 1 and L 2 The options are as follows:

[0133] no 1 =0,n 2 =0,L 1 and L 2 Linked to form -(CH 2 ) n3 -, n 3 1 to 4. Among them, L 1 and L 2 There are no special restrictions on the type of the two reacting to form -(CH 2 ) n3 - can be, for example, L 1 f...

Embodiment 1~13

[0202] The preparation of embodiment 1~13 compound Y-1

[0203]

Embodiment 1~3

[0205] Add 56g of hexadecanoic acid (0.22mol), 12g of N,N-dimethylamino-1,2-propanediol (0.1mol) into a 500mL reaction flask, add 300mL of dichloromethane, stir well and add 27.8g of N, N'-diisopropylcarbodiimide (DIC) (0.22mol) and 0.2g 4-dimethylaminopyridine (DMAP), after fully stirring and reacting at room temperature for 24h, filtered, and the solid obtained after the filtrate rotary distillation was further recombined Through crystallization and purification, 54 g of the product was obtained with a yield of 96.8%.

[0206] According to the above preparation process, the difference is that 62 g of oleic acid and 61 g of octadecatrienoic acid (both 0.22 mol) were used to replace 56 g of hexadecanoic acid in the above preparation process. The yield and product structure of the obtained product are shown in Table 1.

[0207] The productive rate and structure of table 1 embodiment 1~3

[0208]

[0209]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com